Daily cleaning and maintenance

31.10.2002 \\Docuserver\ba\Master\Ba_eng\UM\044_60\UM_A+S\Tglrein.fm 16

VCM 44

6. Daily cleaning and maintenance

After production has been ended, cleaning the VCM 44 should should restore it to a germ-free

condition ready for use. The frequency and intensity of cleaning and disinfection required de-

pend fundamentally on the degree of contamination arising from the production process.

6.1 Cleaning procedure

Cleaning may be carried out manually with scrubbing brushes or with the assistance of ma-

chine functions according to the following table. High pressure hoses should not be used.

Cleaning, disinfection and sterilization are basic requirements of every process in

the food production industry and technology. Additionally, thorough cleaning ex-

tends the life of the machine and in particular the seals considerably. Complete in-

structions for the cleaning and disinfection processes are to be found in the technical

appendix. (See ” Cleaning and disinfection” on page 26.)

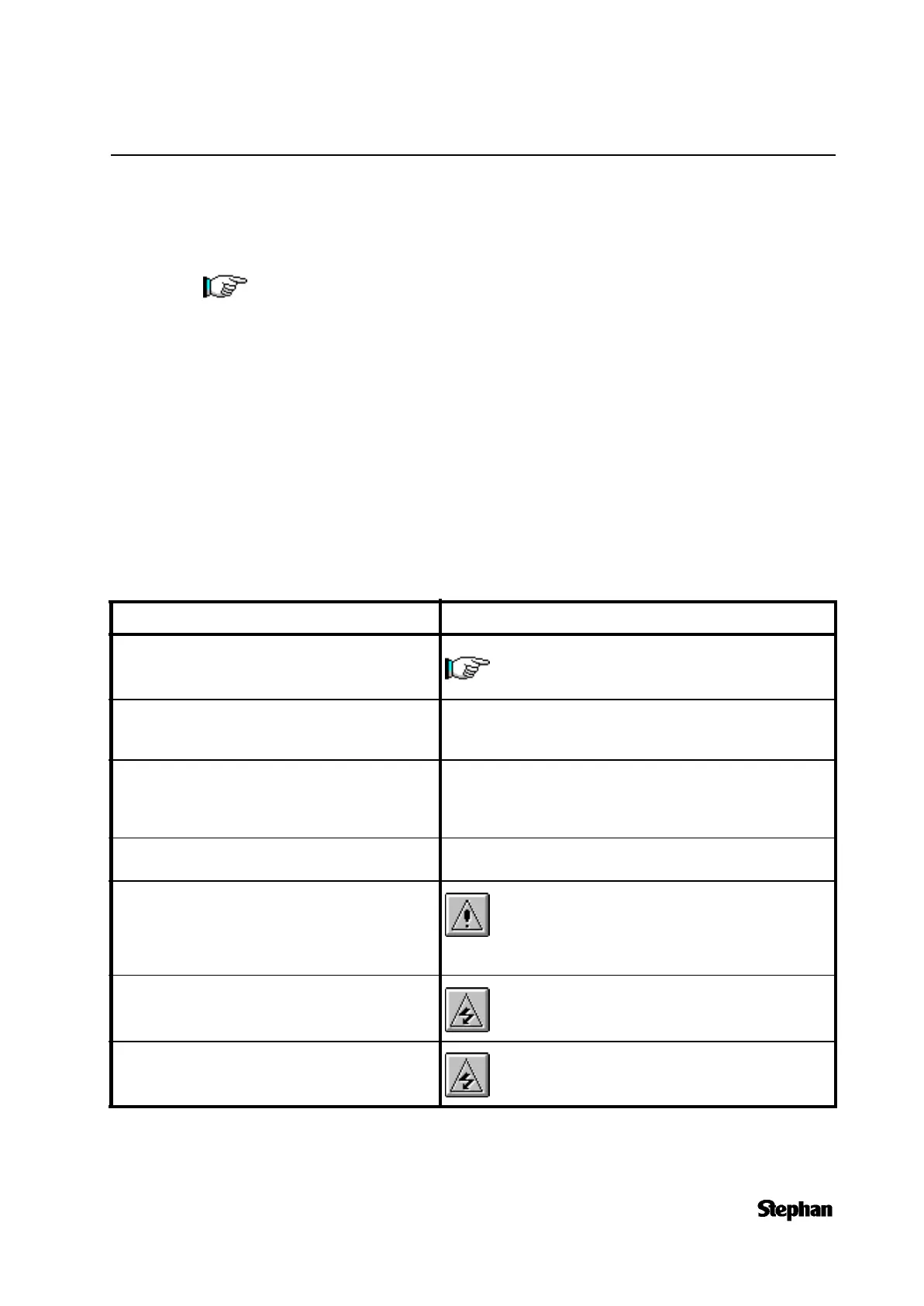

What to do first.. ...and then carry out and double check!

Fill bowl to 2/3 full with warm water and add neutral

detergent with disinfectant action.

.

Fatty contamination is removed by water tempera-

tures over the melting point of fat (50°C).

Close and lock lid.

Turn mixing baffle slowly clockwise.

Switch on main motor at low revs. to start with and

then run for ca. 2-3 minutes at highest speed.

During the removal of protein-containing dirt with wa-

ter over 60°C, coagulated protein may burn in on sur-

faces and should therefore quickly be removed with

the appropriate cleaning materials.

Open toggle seal, open lid, tip and empty bowl.

Rinse with clean water.

manual

Wait until the cleaning water has come to rest to avoid

splash danger.

Remove working insert from the motor shaft and

clean working inserts separately.

Clean the drill holes of the working insert should be

cleaned with a bottle brush.

Remove lid seal from the lid nut, clean and replace.

Take care when handling blades and working inserts.

Never put bare hands into a full bowl. Concealed

blades carry a high risk of cuts and injury.

Lacquered machine parts should be cleaned with a

sponge and mild soapy water.

Never spray down motor, motor casing, switching

cabinet etc., with water or cleaning solutions.

Use only a dry cloth to clean the electric equipment. Electric equipment should only ever be cleaned dryly.

Loading...

Loading...