10 | WPL E | WPL COOL WWW.STIEBEL-ELTRON.COM

INSTALLATION

PREPARATIONS

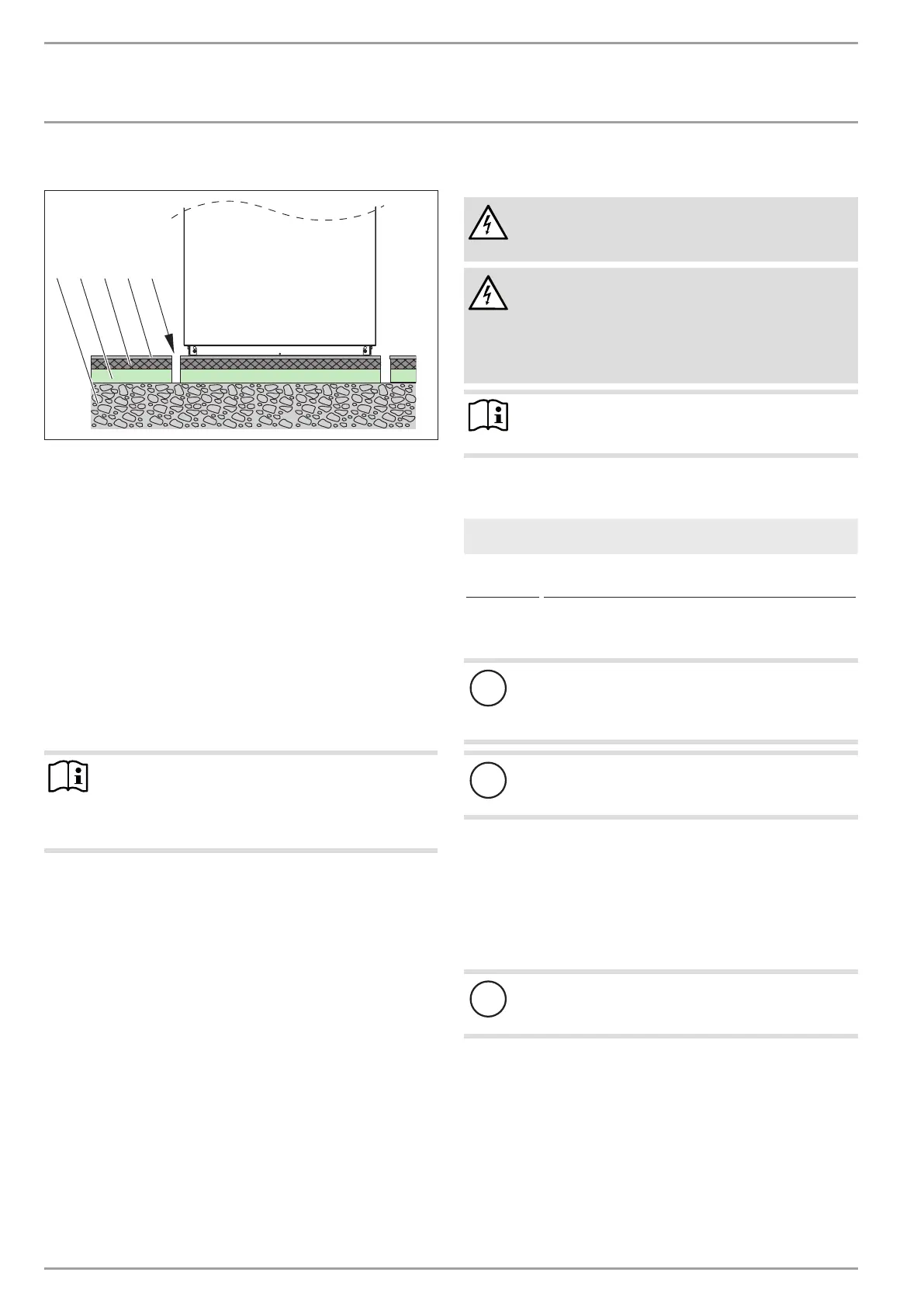

9.3.2 Internal installation

1 2 3 54

26�03�01�1466

1 Concrete base

2 Impact sound insulation

3 Floating screed

4 Floor covering

5 Recess

Isolate the mounting surface around the heat pump by re-

cesses. After completing the installation, seal these recesses

with a water-impervious and sound insulating material, such

as silicone for example.

Observe the following information:

- Connect the heating circuit flow and return lines via flexible

pressure hoses. Suitable pressure hoses are listed in chapter

"Appliance description / Required accessories for internal

installation".

- Protect all pipe fixings and wall transitions with anti-vibra-

tion insulation.

Note

For details of the dimensions and positions of the air

intake and discharge apertures, as well as the outlets for

hydraulic lines and power cables, see chapter "Specifica-

tion / Dimensions and connections / Internal installation".

9.4 Electrical installation

DANGER Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

DANGER Electrocution

Only use a permanent connection to the power supply.

The appliance must be able to be separated from the

power supply by an isolator that disconnects all poles

with at least 3 mm contact separation. This requirement

can be met by contactors, circuit breakers, fuses etc.

Note

The specified voltage must match the mains voltage. Ob-

serve the type plate.

Route cables with the following cross-sections in accordance with

the respective fuse rating:

Fuse protec-

tion

Conductor cross-section

16 A

2.5 mm²

1.5 mm² with only two live wires and routing on a wall or in

an electrical conduit on a wall.

The electrical data is given in the "Specification" chapter. The BUS

cable requires a cable J-Y (St) 2x2x0.8mm².

!

Damage to the appliance and environment

Provide separate fuses/MCBs for the 3 power circuits of

the appliance, the control unit and the electricemer-

gency/booster heater.

!

Damage to the appliance and environment

Provide common fuses/MCBs for the control cable of the

appliance and the heat pump manager.

9.5 Buffer cylinder

A buffer cylinder is recommended to ensure trouble-free appli-

ance operation.

The buffer cylinder is not only installed to provide hydraulic sepa-

ration of the flow rates in the heat pump circuit and the heating

circuit, but also as an energy source for defrosting.

!

Damage to the appliance and environment

A buffer cylinder with diffusion-proof insulation is es-

sential for cooling mode.

Loading...

Loading...