WWW.STIEBEL-ELTRON.COM WPL E | WPL COOL| 13

INSTALLATION

APPLIANCE INSTALLATION

10.3 Heating water connection

!

Damage to the appliance and environment

The heating system to which the heat pump is connected

must be installed by a qualified contractor in accordance

with the water installation drawings that are part of the

technical guides.

Thoroughly flush the pipework before connecting the heat

pump. Debris, such as rust, sand or sealant can impair the

operational reliability of the heat pump.

Connect the heat pump on the heating water side. Check for

tightness.

Connect the flexible pressure hoses to the connectors.

The pressure hoses must be at least 1 metre long.

Structure-borne noise is largely prevented by the anti-vibration

construction of the heat pump and by the flexible pressure hoses,

which act as anti-vibration mounts.

10.3.1 Oxygen diffusion

!

Damage to the appliance and environment

In underfloor heating systems with plastic pipes that are

permeable to oxygen, avoid open vented heating systems

or steel pipework.

With permeable plastic underfloor heating system pipes or open

vented heating systems, oxygen diffusion can cause corrosion of

steel components if steel radiators or steel pipes are used.

The products of corrosion, e.g. rusty sludge, can settle inside the

heat pump condenser and can result in loss of output through

reduction of the cross-section, or in a heat pump shutdown.

10.4 Second heat source

For dual mode systems, always connect the heat pump into the

return of the second external heat source, e.g. oil boiler.

10.5 Filling the heating system

10.5.1 Water quality

A fill water analysis must be available prior to charging the sys-

tem. This may, for example, be requested from the relevant water

supply utility.

!

Material losses

To avoid damage as a result of scaling, it may be neces-

sary to soften or desalinate the fill water. The fill water

limits specified in chapter "Specification / Data table"

must always be observed.

Recheck these limits 8-12 weeks after commission-

ing and as part of annual system maintenance.

Note

With conductivity of >1000μS/cm, desalination treatment

is recommended in order to avoid corrosion.

Note

Suitable appliances for water softening and desalinating,

as well as for charging and flushing heating systems, can

be obtained via trade suppliers.

Note

If you treat the fill water with inhibitors or additives, the

same limits as for desalination apply.

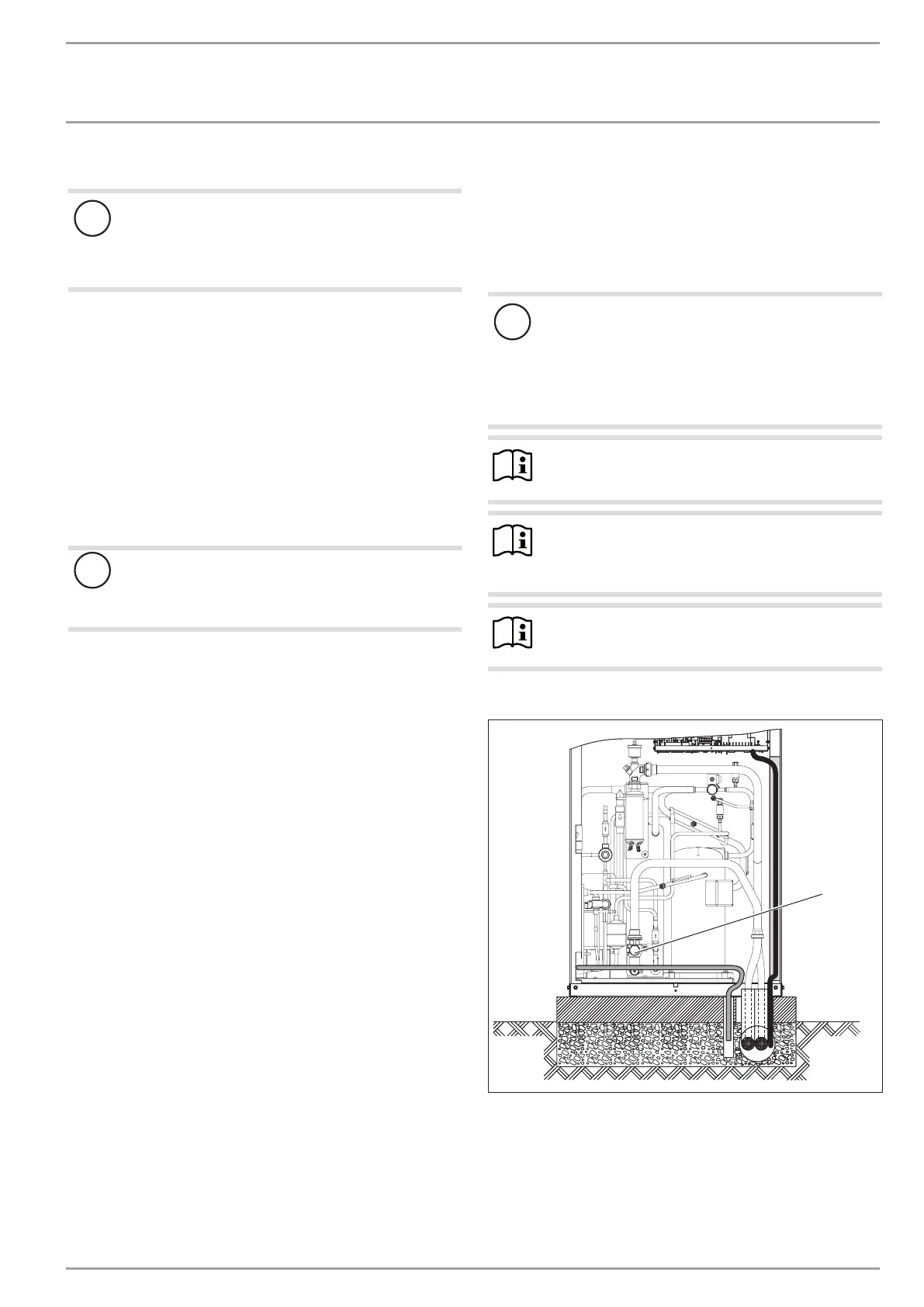

10.5.2 Filling the heating system

26�03�01�0958�

1

1 Drain

Fill the heating system via the drain.

After filling the heating system, check the connections for

tightness (visual and physical inspection).

Loading...

Loading...