26 Series 4180 Powerhead

– Adjust engine idle speed with the

aid of a tachometer,

b

3.1;

note that there is an ignition

spark on every revolution of

the crankshaft.

– Check idling behavior by opening

the throttle several times. Make

sure engine idles and

accelerates smoothly.

If the engine stops while idling:

– Turn the idle speed screw

clockwise until the attachment

begins to run. Then turn the

screw back one quarter of a turn

from that position

If the attachment runs while the

engine is idling:

– Turn idle speed screw

counterclockwise until the

attachment stops running. Then

turn the screw about another

quarter turn in the same direction.

A slight correction of the setting of

the high speed screw (H) may be

necessary (no further than stop) if

engine power is not satisfactory

when operating at high altitude, sea

level or after changing the

attachment.

– Turn the high speed screw H

clockwise (leaner) at high altitude

or counterclockwise (richer) at

sea level.

The limiter caps only need to be

removed from the screws if it is

necessary to replace the high speed

screw (H) or low speed screw (L),

clean the carburetor or carry out the

basic setting, b

6.4.1.

Remove the limiter caps to carry out

the basic setting:

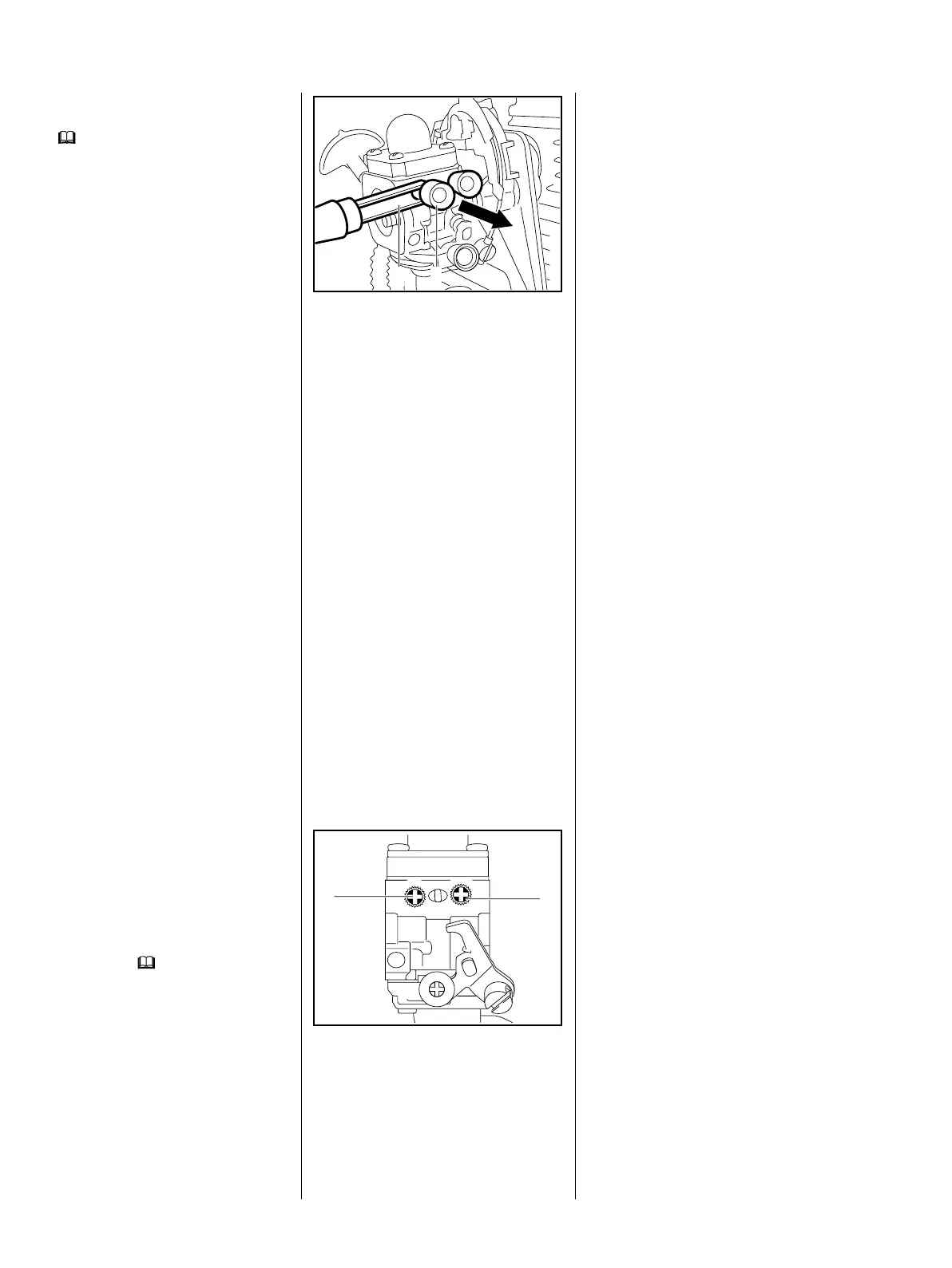

: Push the puller

5910 890 4501 (1), with the

groove facing the limiter cap,

between the limiter cap (2) and

carburetor body.

VA

21

: Pry off the cap (2). If the limiter

cap is stuck on the adjusting

screw, turn the puller over so that

its groove faces the carburetor

body. Pry off the limiter cap.

The basic setting must be carried

out after removing the limiter caps.

Do not re-install used caps because

they may have been damaged

during the removal process.

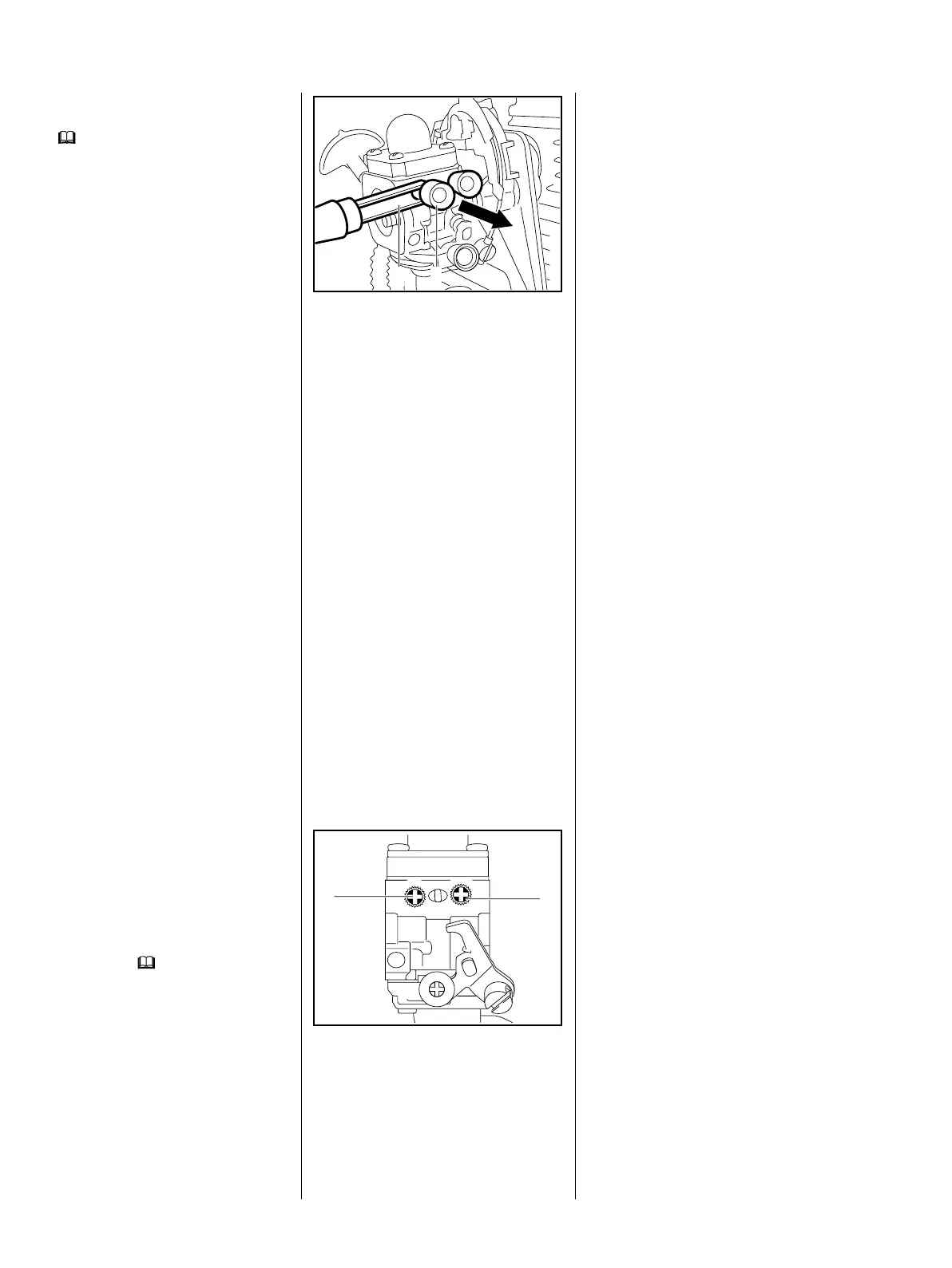

: Carefully screw the high speed

screw H (1) and low speed

screw L (2) clockwise down onto

their seats.

VA

2

1

The basic setting is carried out with

the high speed screw H and the low

speed screw L as follows:

FS 90; FC 90, 95; KM 90

(C1Q-S110)

– Open the high speed screw H

3 1/2 turns counterclockwise.

– Open the low speed screw L

1 1/4 turns counterclockwise.

FS/FC/KM 100, 110; HT 100, 101

(C1Q-S72, C1Q-S81, C1Q-S88)

– Open the high speed screw H

2 turns counterclockwise.

– Open the low speed screw L

3 turns counterclockwise.

FS/KM 130; HT 130, 131

(C1Q-S98)

– Open the high speed screw H

4 turns counterclockwise.

– Open the low speed screw L

2 3/8 turns counterclockwise.

FS/KM 130; HT 131

(C1Q-S114) Brazil only

– Open the high speed screw H

2 1/2 turns counterclockwise.

– Open the low speed screw L

2 5/8 turns counterclockwise.

6.4.1 Basic Setting

Loading...

Loading...