40 Series 4180 Powerhead

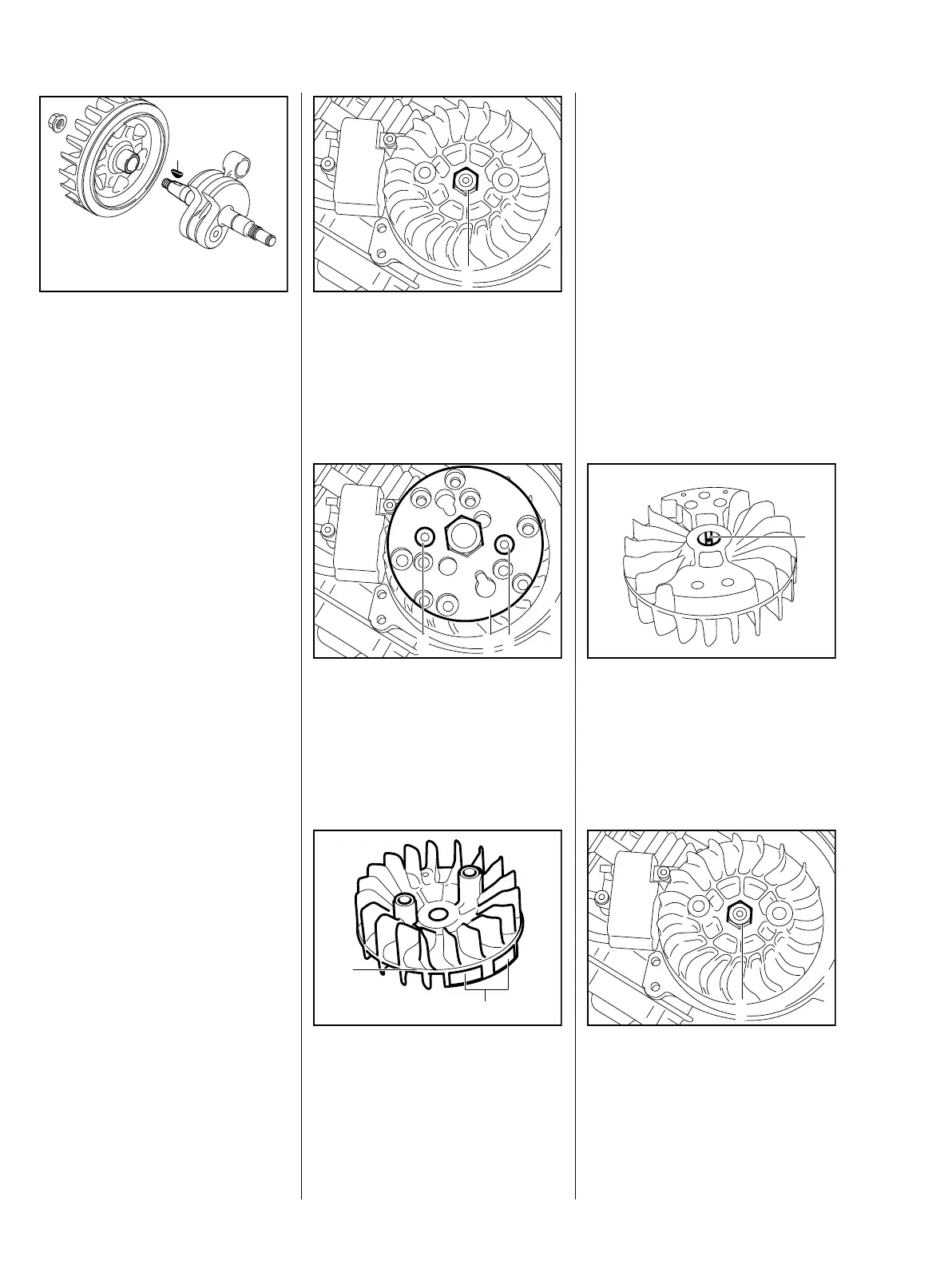

: Crankshaft (1) and flywheel (2)

are an interference fit.

The crankshaft and flywheel are

pressed together with such force

that the flywheel cannot turn on the

crankshaft.

For this reason the mating

surfaces must be free from

grease and oil.

The conical interference fit ensures

the flywheel is exactly centered, and

runs smoothly with a minimum of

runout.

: The key (3) is used only to

position the flywheel in relation to

the crankshaft (correct ignition

timing).

: The nut (4) pushes the flywheel

(2) onto the crankshaft (1) to

achieve the required interference

fit.

– Remove the clutch, b 7.6.1

: Remove the hex. nut (1).

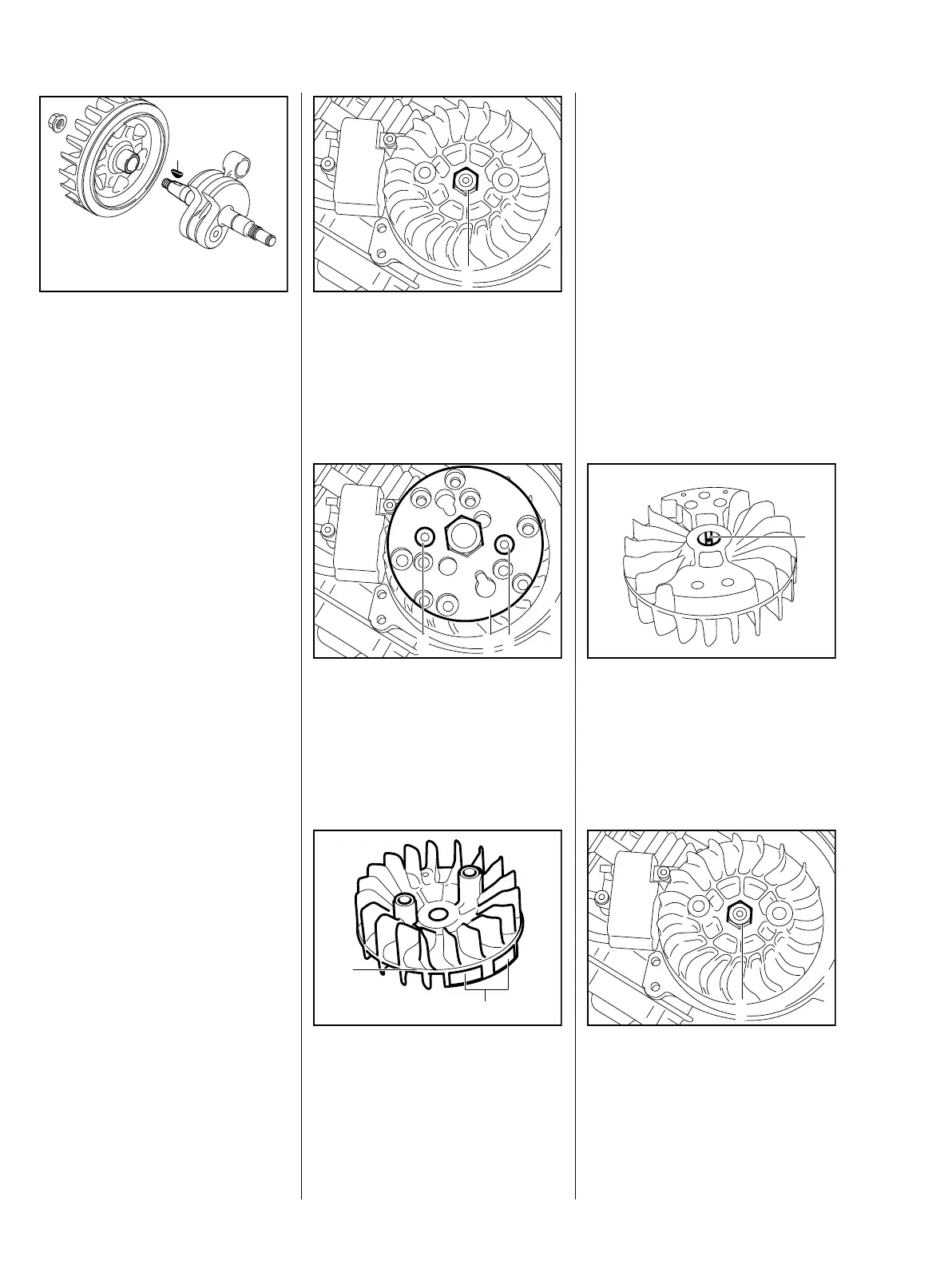

: Mount puller (1) 4119 890 4501

to the flywheel with M6 x 25

screws (2 and 3), and pull off the

flywheel.

: There must be no signs of cracks

or other damage on the flywheel

(1) and magnet poles (2).

If this is the case, install a new

flywheel.

Installing the flywheel

– Clean the stub of the crankshaft

and the flywheel hub bore with a

standard commercial, solvent-

based degreasant containing no

chlorinated or halogenated

hydrocarbons, b 12

– Check Woodruff key or integrally

cast key for damage and replace

key or flywheel if necessary.

: Fit the flywheel in position.

Make sure it is properly seated.

Key (1) in flywheel must engage

slot in crankshaft stub.

: Fit the hex. nut (1) and tighten it

down firmly, b 3.4

– Install the clutch, b 7.6.2

7.7 Flywheel

Loading...

Loading...