© STIHL Inc., Virginia Beach, VA 2013 US/STR

confidential

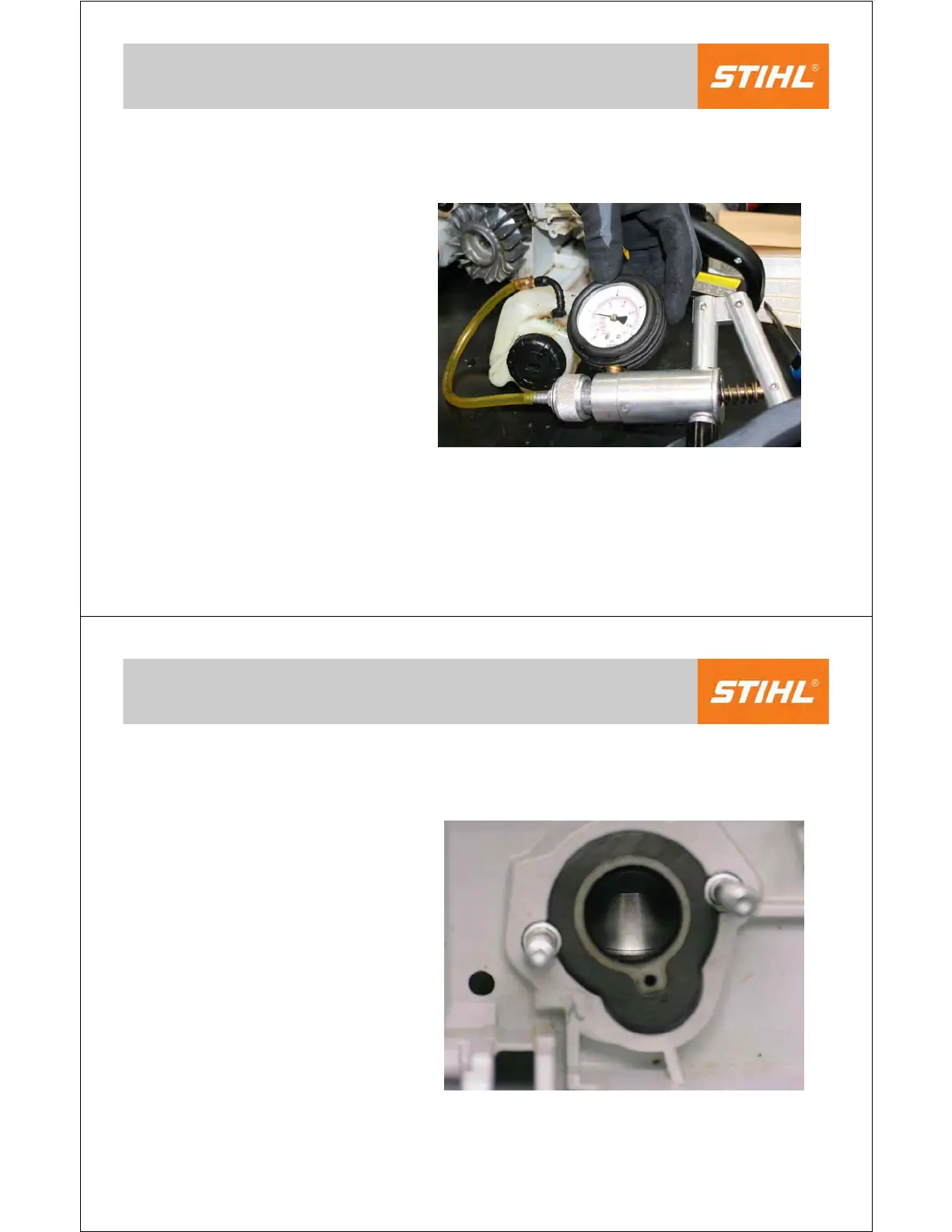

23. Vacuum Test Tank Vent

Reverse the tester into

vacuum mode and pump

hard and fast to see the

needle indicates that

some negative pressure

is present in the tank

Stop pumping and watch

the gauge and the

needle should move

back up towards zero

rapidly

If the needle does not

leak back to zero quickly

the tank vent must be

replaced and then re-test

© STIHL Inc., Virginia Beach, VA 2013 US/STR

confidential

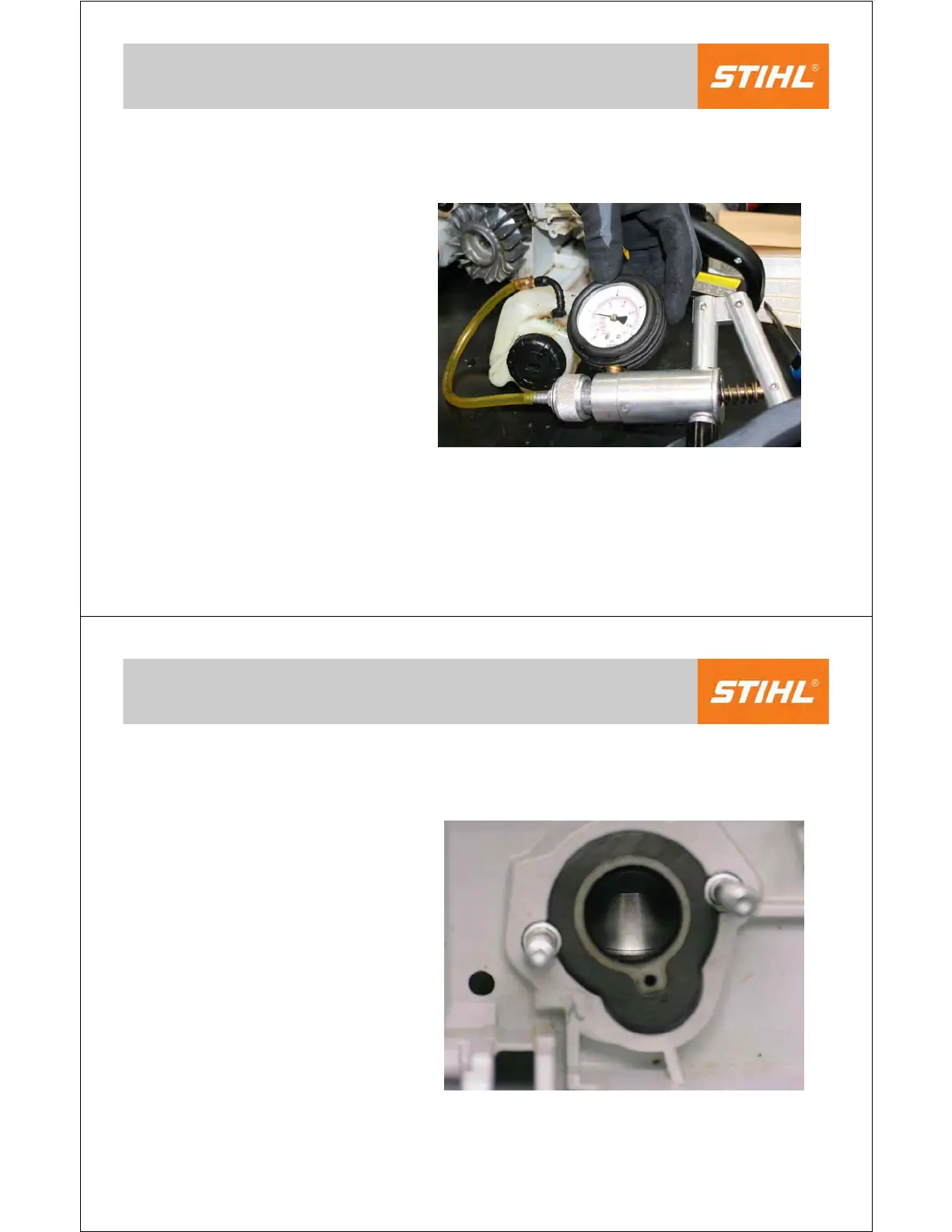

24. Inspect Intake Side Of Piston

With the carb removed

look through the inlet port

and rotate the crankshaft

to inspect the intake side

of the piston

The machine marks

should be present on a

piston in good condition

Scoring or a dull gray

appearance would

indicate lack of

lubrication, dirt ingestion,

or possibly other

problems that would

prevent the engine from

running properly

Loading...

Loading...