15

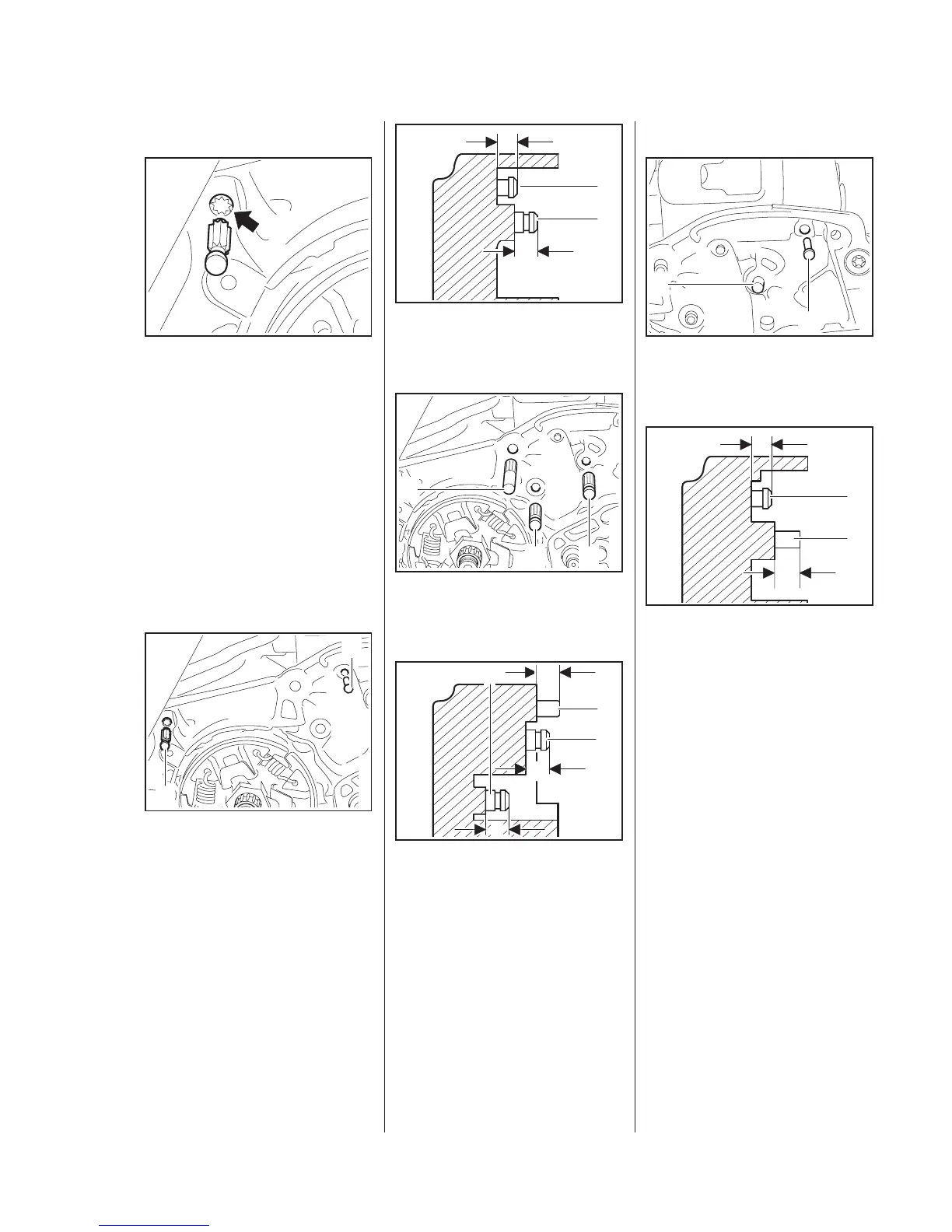

: Position the new pin in the

bore (arrow) so that the knurling

on the pin meshes with the

existing knurling in the bore.

Turn pin back and forth as

necessary.

The pins must be driven home

squarely.

: Drive home the pins (1 and 2) as

specified below.

5902RA075 TG5902RA076 TG

1

2

: Pin (1) a = about 2.9 - 3.3 mm

Pin (2) b = about 4.3 - 4.7 mm

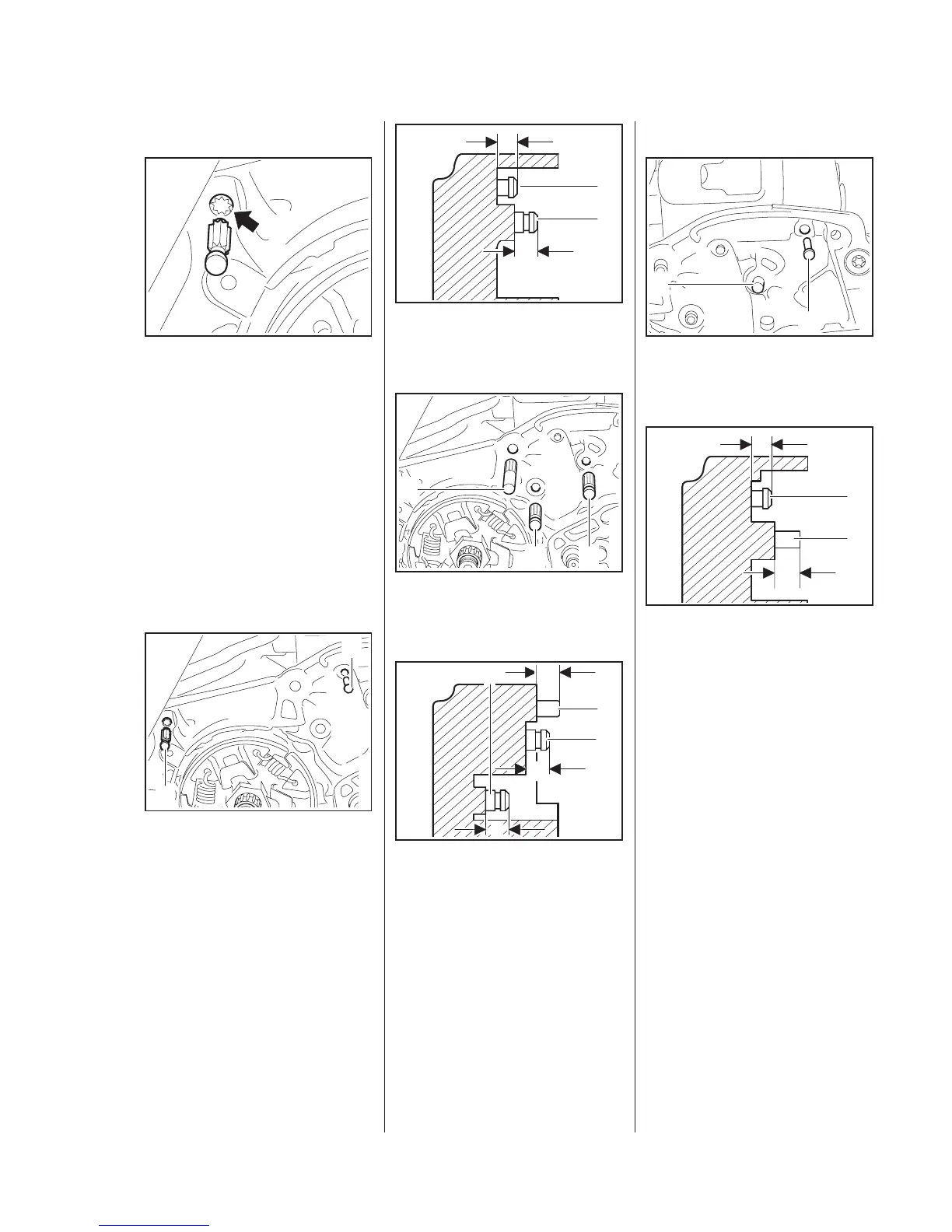

: Drive home the pins (3, 4 and 5)

as specified below.

: Pin (3) a = about 10.3 - 10.5 mm

Pin (4) b = about 4.6 - 4.8 mm

Pin (5) c = about 5.1 - 5.3 mm

a

b

0001RA061 TG

1

2

5902RA077 TG

4

3

5

a

c

b

3

4

5

0001RA063 TG

Machines with QuickStop Super

: Drive home the pins (5 and 6) as

specified below.

: Pin (5) b = about 5.9...6.1 mm

Pin (6) a = about 2.9...3.3 mm

– Reassemble all other parts in the

reverse sequence.

– Lubricate the brake and cam

levers, b

Loading...

Loading...