48 MS 261, MS 261 C

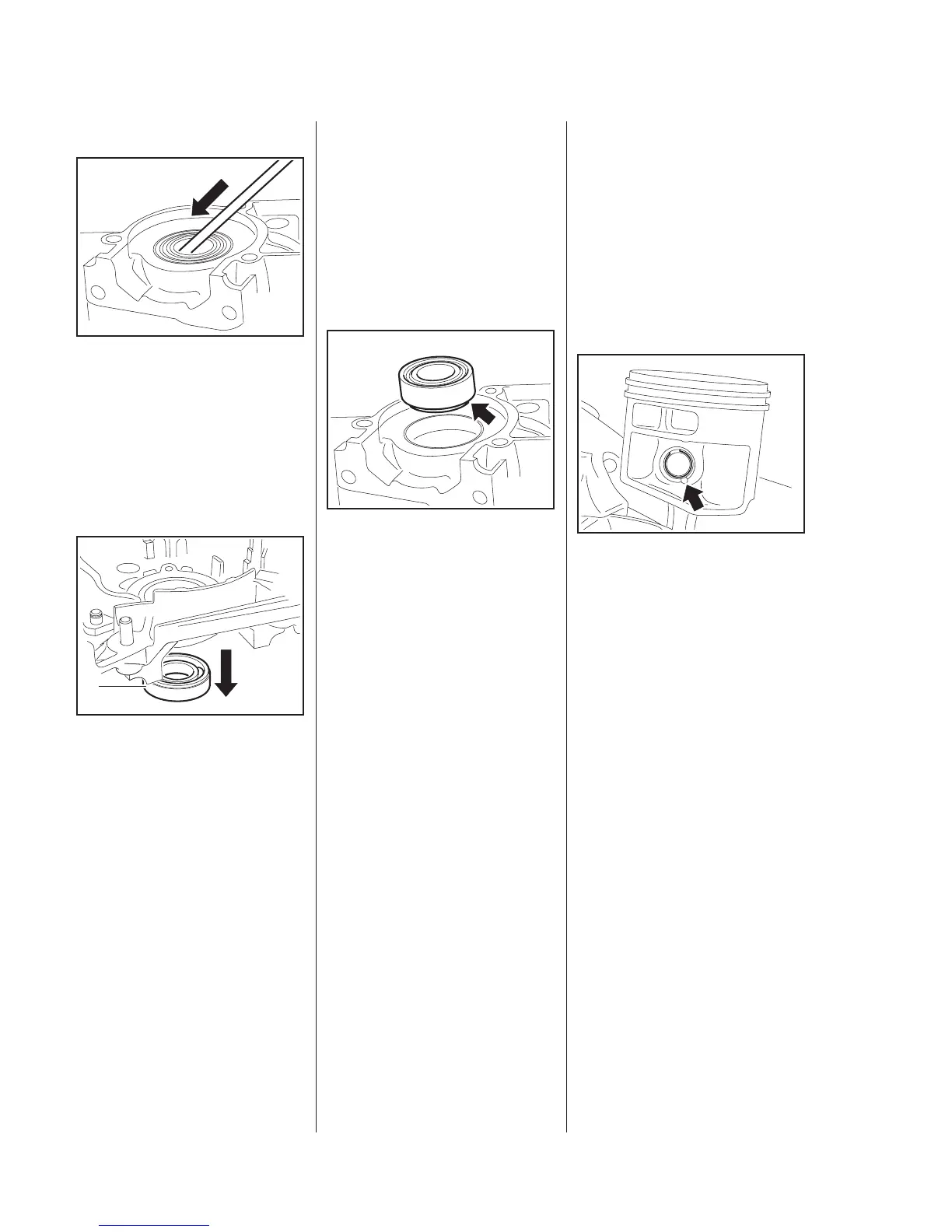

Clutch side of crankcase

: Use a punch to carefully drive out

the oil seal.

– Check and clean the crankcase

or replace if necessary.

– If this half of the crankcase is in

order, install a new ball bearing.

– Heat the area of the bearing seat

to about 160°C (320°F).

The bearing (1) drops out as soon

as this temperature is reached.

5902RA149 TG5902RA150 TG

1

Installing

As the bearing seat in the clutch half

of the crankcase has no locating

face, the oil pump must be installed

first

– the oil pump serves as a locating

face.

– Install the oil pump, b

11.3

– Heat the area of the bearing seat

to about 160°C (320°F).

– Position the ball bearing so that

the centering ring (arrow) points

toward the oil pump.

: Push the ball bearing home as far

as stop (oil pump).

This operation must be carried out

quickly because the bearing

absorbs heat and begins to expand.

– Check that ball bearing is

properly seated. If necessary,

use press arbor 1118 893 7200 to

carefully press the bearing fully

home until it butts against the oil

pump.

– Remove the oil pump,

11.3

– Install the crankshaft,

6.6

– Install the oil seals,

6.3

– Reassemble all other parts in the

reverse sequence.

5902RA151 TG

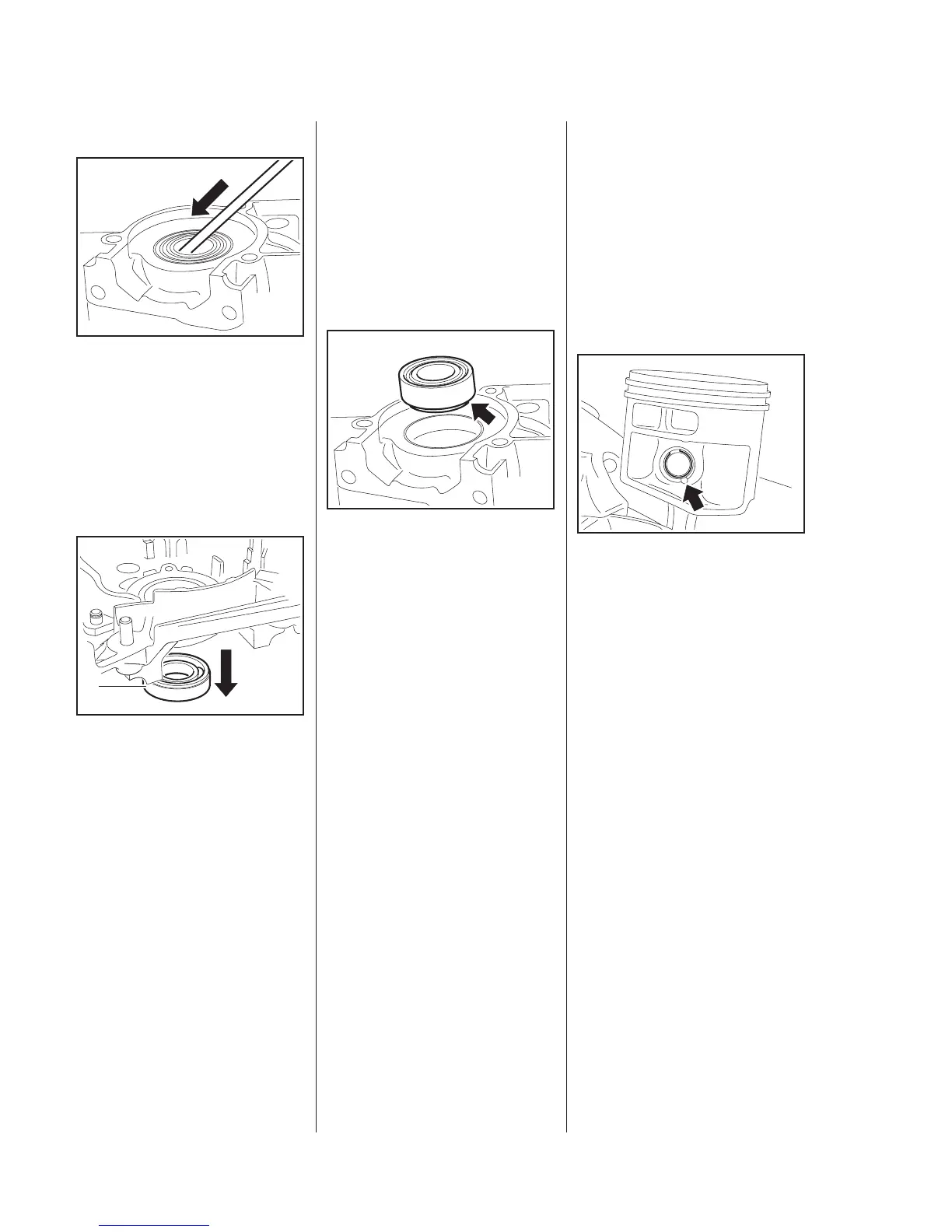

6.7 Piston

Before removing the cylinder,

decide whether or not the

crankshaft has to be removed as

well, b

6.6

– Remove the cylinder,

6.5

It is not necessary to remove the

snap ring at the clutch side.

: At the ignition side, apply a

suitable tool to the recess (arrow)

and ease the hookless snap ring

out of the piston boss.

5902RA152 TG

Loading...

Loading...