18 TS 350

Mounting the abrasive Wheel

The engine must be switched off and the arbor blocked

before mounting or removing the abrasive wheel. To do

this, push the locking pin squarely through the hole in the

V-belt guard. If one of the V-belt pulley spokes is in the

way, use the combination wrench to turn the arbor until the

locking pin can be inserted.

Slacken off and remove the M 10 hex. head screw with the

combination wrench (17 mm) and take it off the arbor

together with the front thrust washer.

The cutting wheel can now be pulled off the arbor and

taken out of the guard. This operation is made easier if the

blade guard is turned so that its lower edge is vertical.

Before fitting the new abrasive wheel, check that the rear

thrust washer is positioned so that the notch in its center

hole engages over the lug on the arbor.

Mount the new abrasive wheel in the reverse sequence to

that described above. Make sure that the locking tab on

the front thrust washer engages in one of the two slots in

the arbor. Use combination wrench to securely tighten the

M 10 hex. head screw.

Pay attention to arrows for direction of rotation when fitting

a diamond abrasive wheel.

If a wider kerf is required (e. g. for installing induction

loops in road surfaces), two diamond abrasive wheels

can be used side by side. In such a case it is essential to

ensure that the segments of both wheels are positioned

exactly next to one another.

Important! Two composite wheels must never be used

simultaneously, for they may break and cause injuries

as they wear down unevenly.

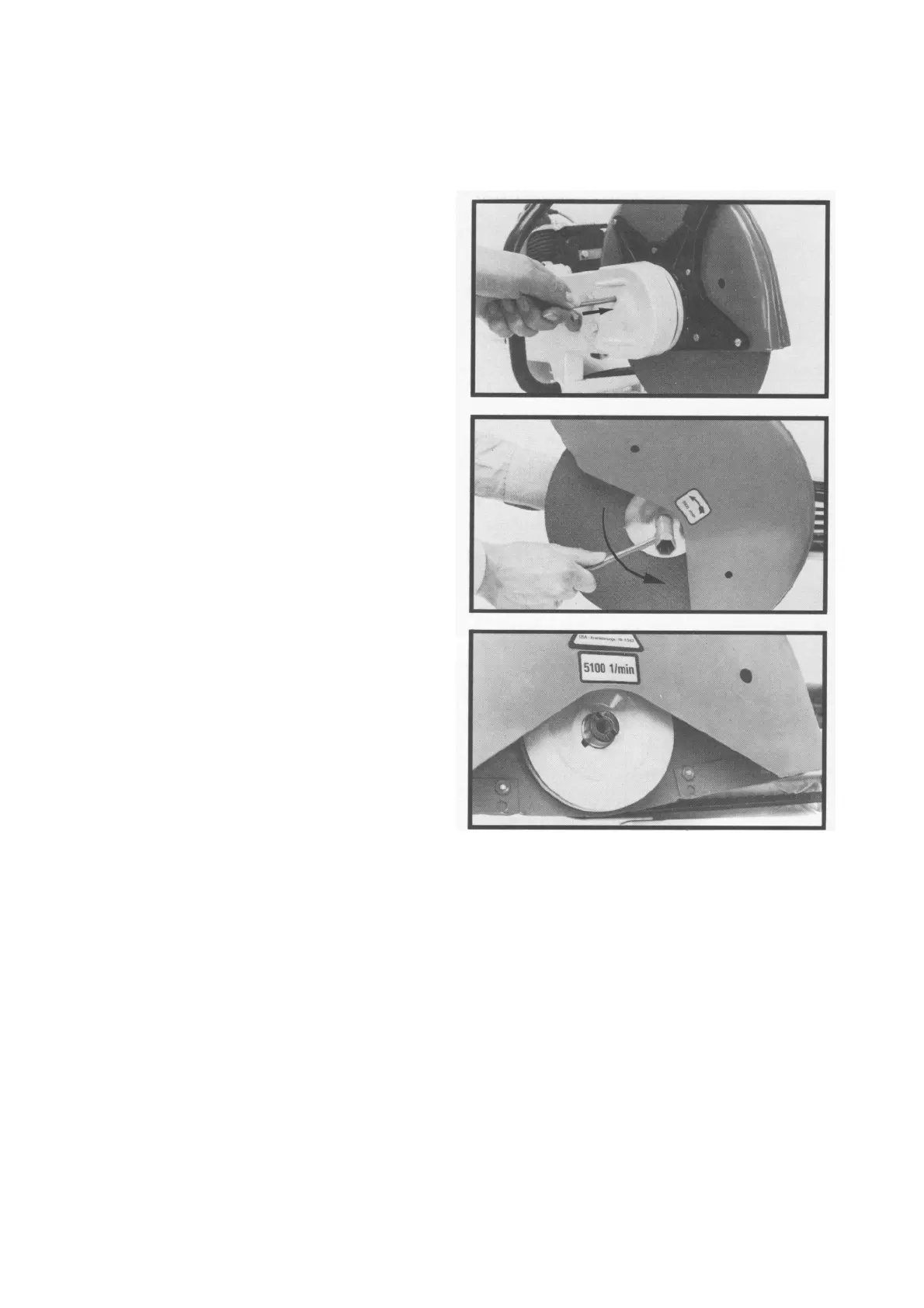

Top: Blocking the arbor

Center: Removing hex. head screw

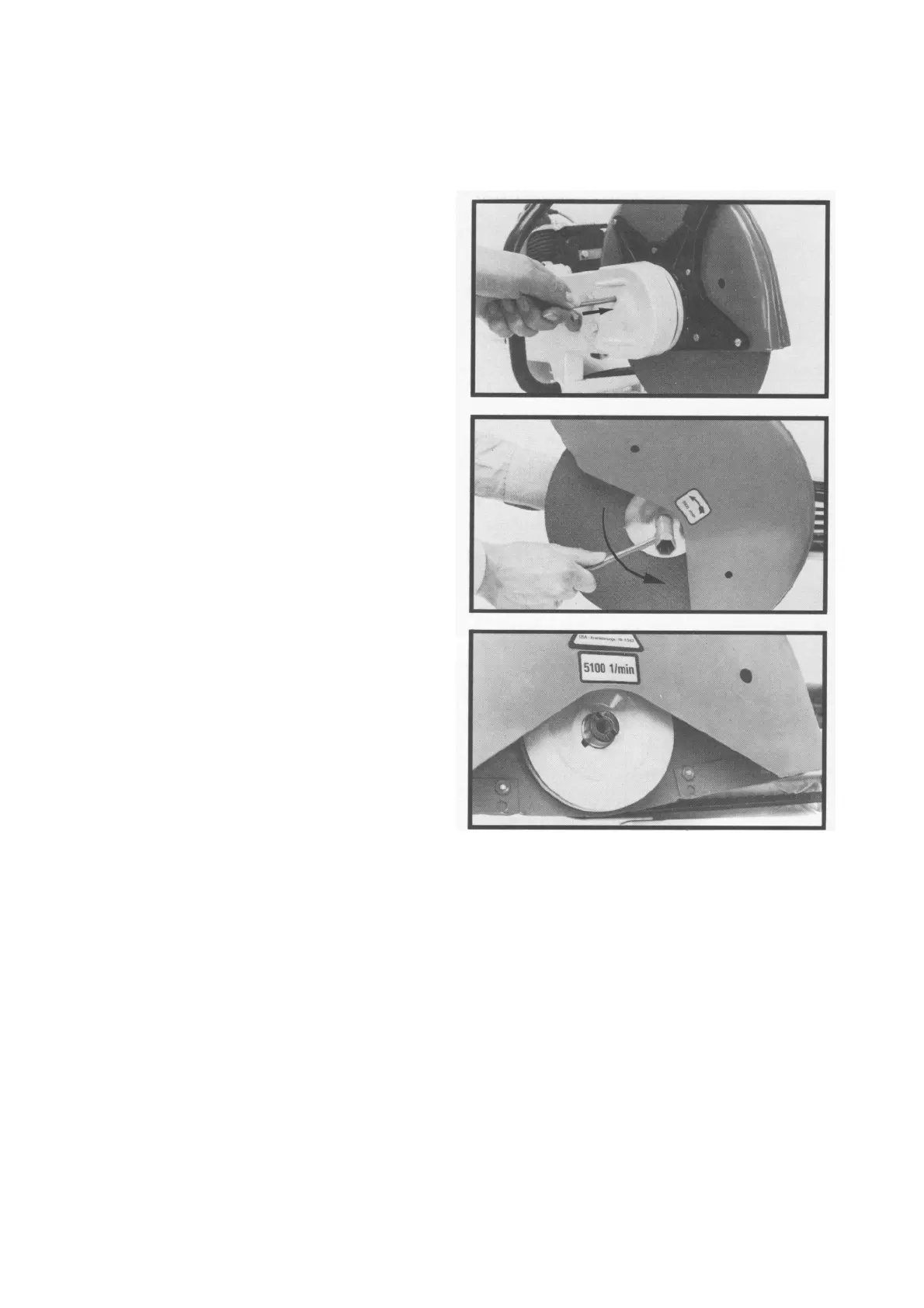

Bottom: Rear thrust washer correctly positioned

Loading...

Loading...