Working safely with cut-off machines

English

15

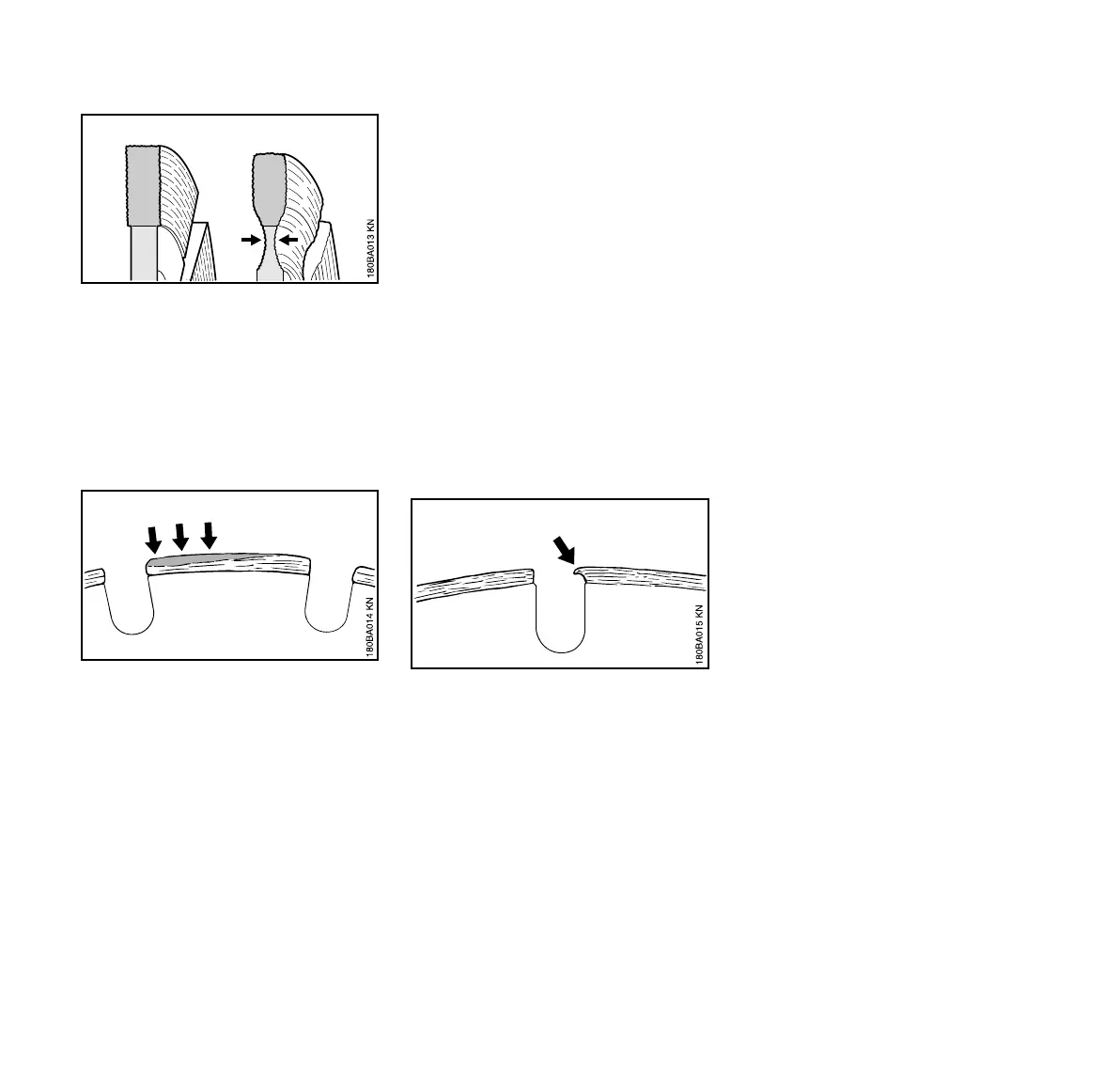

Undercut

Do not cut into the base course

(frequently chipped stones and gravel)

when cutting roadway pavement –

cutting in chipped stones and gravel is

revealed by light-colored dust –

excessive undercut may occur as a

result – Danger of shattering!

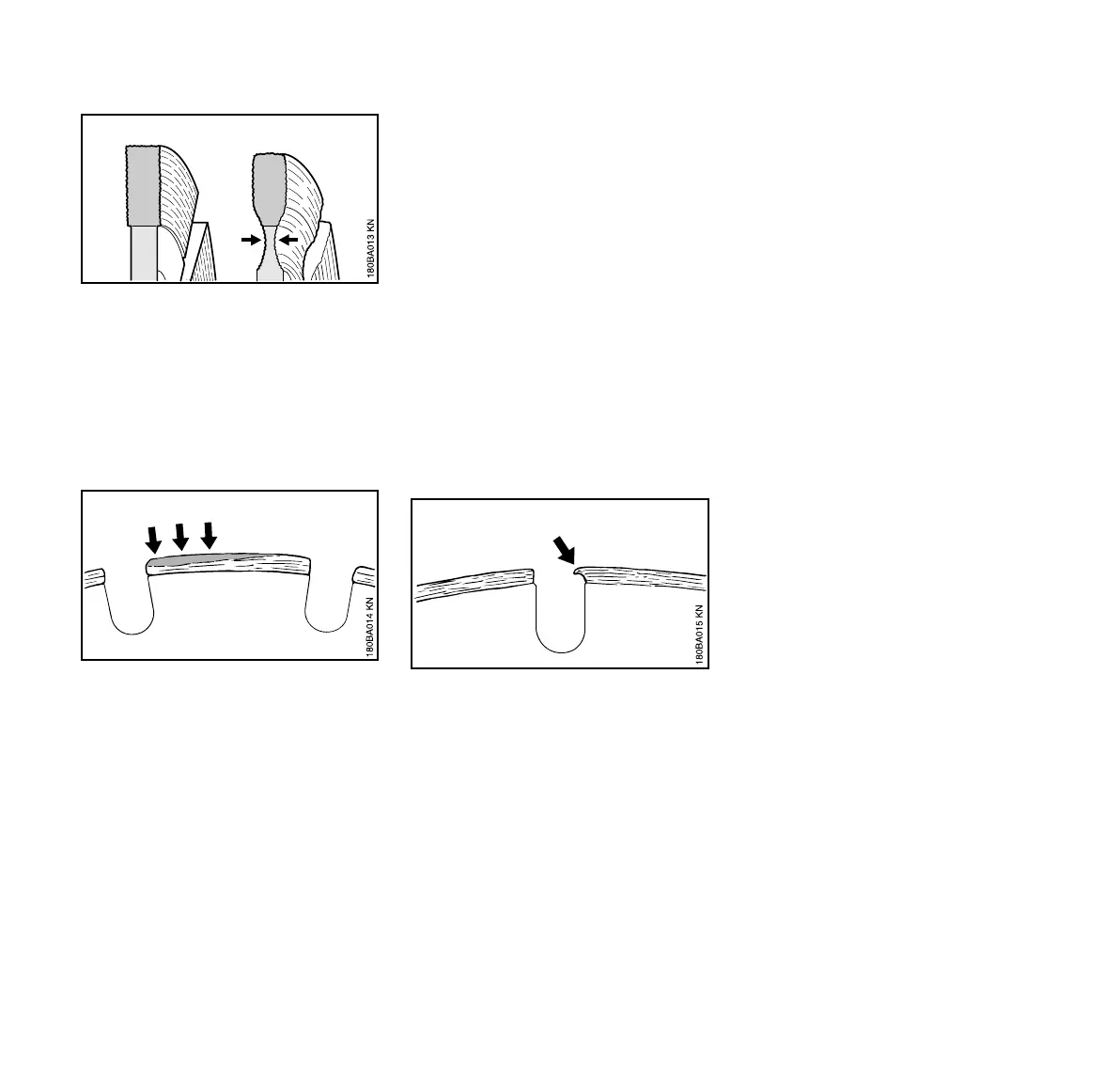

Built-up edges, sharpen

Built-up edges take the form of a light

gray deposit on the tops of the diamond

segments. This deposit on the segments

clogs the diamonds and blunts the

segments.

Built-up edges can form:

– when cutting extremely hard

materials, e. g., granite

– with incorrect handling, e. g.,

excessive feed effort

– if excessively large cross-sections

are cut without pendulum cutting

(movement back and forth in the

cutting plane)

Built-up edges increase vibration,

reduce cutting performance, and cause

formation of sparks.

At the first signs of built-up edges,

immediately "sharpen" the diamond

cutting wheel – to do this, briefly cut

through abrasive material such as

sandstone, aerated concrete or asphalt.

Addition of water prevents the formation

of built-up edges.

If work continues with dull segments,

these may soften due to the high heat

generated – the parent wheel is

annealed and its strength is

compromised – this can lead to stresses

that are clearly recognizable by

gyrations of the cutting wheel. Do not

continue to use the cutting wheel – Risk

of accident!

Loading...

Loading...