Pull sealing

tape back

Remove the plug

New

thumbwheel

Remove insert

The text in brackets refers to the corresponding user guide

chapter. [Chapter Number]

TIP COMPATIBILITY [2]

IDENTIFYING TIPS [3]

PLATEN VACUUM [4]

Make sure the vacuum indicator on the Operator Touchscreen

is green and showing that a small or large build sheet is in

place on the platen.

USING BUILD SHEETS [4]

Use clear build sheet for ABS-based, ASA, PC, PC-ABS, ST130.

Use smoky gray build sheet for ULTEM resin, PPSF, Antero.

Use green tinted build sheet for Nylon-based materials.

INSTALLING CANISTERS [4]

Remove the anti-rotation plug from side of canister before

use. Seal hole with sealing tape. Make sure the rubber

shipping insert is removed from the thumbwheel door

before building. Do not remove rubber shipping insert until

the canister is loaded into the canister bay.

Storing Canisters

Always replace the rubber shipping insert when storing a

partially used canister. Store canister vertically (as if it is

installed in a system) or cross-winding of the filament

on the inner spool may result.

CHANGING TIPS OR MATERIAL TYPE [4]

1. Remove the used build sheet from platen.

2. Clean the oven and tip wipe assembly.

3. Inspect the tip wipe assembly.

4. From the Build Screen, select Material/Tools and then select

Tips/Materials Change. Follow the screen prompts to

change tips.

The Tip Wizard will guide you through the process.

108313-0009_REV_C

The system automatically does the following:

- Unloads model and support

- Waits for oven to stabilize

- Performs Auto Z Zero Calibration

- Performs Auto Tip Calibration

- Loads model and support material*

- Builds a Calibration Job*

* Requires button to be pressed by user and then user

placement to build the calibration box.

7. Select the circle next to the desired tip. A black dot in the

center indicates which tip is selected.

AUTO COOLDOWN FEATURE [4]

This option acts as an energy saver when PC, PC-ABS, ULTEM

resin, or PPSF materials are being used. It also helps to prevent

parts from cracking when building large, thick parts using PPSF.

After building completes, the oven gradually cools to the standby

temperature. Wait until the PPSF parts are cool before removing

them from the oven. To use this feature go to the Administrator

screen, select System Default and then set Auto Cool Oven

to On or after the job.

STABILIZING OVEN [4]

When changing material type or using Auto Cool-Down, allow

oven temperatures to stabilize before calibration and system

use. Oven stabilization times are as follows:

Table 1-3: Oven Stabilization Times (Software V.3.27 and later*)

5. When changing liquefier tips.

Note: Worn tips cause part quality issues and can lead to loss

of extrusion. Always replace tips when prompted (reset

tip odometers).

Make sure

tip is fully

inserted into

block

6. When changing material type:

- Remove the canisters. If removing a partially used

canister, you must remove it immediately (within ten

seconds) after separating drive block from canister; otherwise

the filament is forced into the canister, making it unusable.

- Seal the canisters and store vertically.

- Insert new canisters and turn the thumbwheel to put

the canister in the “Ready”

state (flashing LED).

- If the removed tips are to be

re-used later, record material

type and volume.

- Make sure that you insert the

tip fully into the heater block.

Note: If material type is changed, the tips MUST be changed.

Do not use the same tip for different material types.

- Select Review Materials to Load and choose materials to load.

- Select Menu to continue.

All unused model and support

tips are interchangeable -

EXCEPT for Soluble

Release (SR) support tips.

Once a tip is used, it is

committed to that material

type and is no longer

interchangeable.

Tip size is imprinted on

the top side of the plate

(T12, T14, T16, T20)

The Soluble Release

support tip is shorter

than standard tips.

Tip size is imprinted on

the top side of the plate

(T12SR20, T12SR30,

T12SR100).

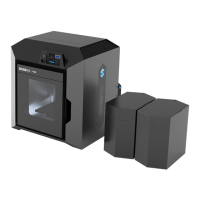

QUICK REFERENCE CARD

Fortus 900mc/F900

Table 1-2: Slice Height

Model Tip Slice Heigh t

T12

0.007 in. (0.178 mm)

T20 0.013 in. (0.330 mm)

T14

0.010 in. (0.254 mm)

T16, T16A, T20C, T20D

0.010 in. (0.254 mm)

T20B 0.013 in. (0.330 mm)

T40A 0.020 in. (0.508 mm)

Table 1-1: Available Tips

Material Model Tip Support Tip

ABSi*

ABS-M30

ABS-M30i

ABS-ESD7

T12, T16, T20

T12, T16, T20

T12, T16

T12SR20*

T12SR20* /

T12SR30

T12SR30

ASA T10, T12, T16, T20

T12SR30

Nylon 12

PC

PC-ABS

PC

PC-ISO

PPSF

TM

ULTEM 9085 resin

T12, T16, T20

T12, T16, T20

T12, T16, T20

T16, T20

T12

T16

T16, T16A, T20

T12SR100

T12SR100

T12SR20* / T12SR100

T16

T12

T16

T16

ULTEM 1010 resin

T14, T20

T16

T40A

T20B

ST130 T20B

T20

T40A

T20

Nylon 6 T16, T20

T12SR100

0.005 in. (0.127 mm)

T10

Nylon 12CF T20C

T12SR100

ANT 800NA T20D

T16

* For oven stabilizing times prior to software V.3.27, please consult

the appropriate user guide.

ANT 840CN03 T20D

T16

* Available on Fortus 900mc only, not F900

ULTEM™, 9085, and 1010 are trademarks of SABIC, its affiliates or subsidiaries.

Oven Stabilization

Times (Hours)

All ABS, ASA, ST130

& Nylons

PC & ULTEM 9085

resin & Antero

All ABS, ASA,

ST130 &

Nylons

PC & ULTEM

9085 resin &

Antero

Loading...

Loading...