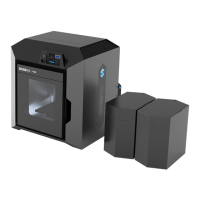

The Stratasys F3300 3D Printer is a multi-extruder Fused Deposition Modeling (FDM) system designed for smart manufacturing environments. It represents the first product in the new F3000 series platform, aiming to deliver leading FDM performance in terms of throughput, part quality, and reliability. The F3300 is engineered to produce jigs, fixtures, and production parts that surpass expectations in build time, cost, and quality. It also offers users enhanced return on investment (ROI) through features like traceability, data analytics, and future expansion capabilities, providing advanced 3D printing for intelligent industrial performance.

Technical Specifications:

- Build Area: The printer boasts a maximum build area of 600 x 600 x 800 mm (23.6 x 23.6 x 31.5 inches), allowing for the creation of large parts.

- Dimensions (Uncrated):

- Width: 203.2 cm (80 inches)

- Depth: 162.6 cm (64 inches)

- Height (Without light tower): 218.4 cm (86 inches)

- Height (With light tower): 236.2 cm (93 inches)

- Weight:

- Crated: 1724 kg (3800 lbs)

- Uncrated: 1360 kg (3000 lbs)

- Power Requirements:

- Dedicated circuit: 50 Hz/60 Hz (47 to 63 Hz)

- Phase: 3-phase, 5-wire wye (L-L-L-N-G)

- Voltage: 208VAC

- Current: 30A circuit

- Input voltage tolerance: ±10% from nominal (187 to 229VAC)

- Peak operating current: 23A

- Leakage (touch) current: <1.0mA (under all conditions)

- The system requires a disconnecting means that is readily accessible and within sight of the printer during operation, with connection methods including cord and plug attachment or direct wiring. Installation must comply with all applicable electrical codes.

- Compressed Air Requirements:

- Supply pressure: 90-110 psi

- Minimum flow: 13 SCFM

- Temperature: Less than 35°C (95°F)

- Condition: Non-lubricated, non-condensing

- Connection: Dimensional standard A-A-59439, 3/8” Body Size (also conforms to ISO 6150-B-15 standard).

- DIN ISO 8573-1 Quality: Particles Class 4, Humidity and liquid water Class 4, Oil Class 2.

- LAN Connection:

- Type: 100 base T, Ethernet protocol, RJ45 connector

- Cable: One 4.57 m (15 foot) CAT6, 10/100 base T cable supplied.

- Configuration: Functions in either DHCP or Static IP configurations.

- Environmental Requirements:

- Operating Temperature: 15°C to 30°C (60°F to 86°F)

- Operating Relative Humidity: 20% to 80% non-condensing

- Storage Temperature: 0°C to 35°C (32°F to 95°F)

- Storage Relative Humidity: 20% to 90% non-condensing

- Material Storage Temperature: 13°C to 30°C (55°F to 86°F)

- Material Storage Relative Humidity: Less than 70%

- Altitude: Shall not exceed 3000 m (9843 ft)

- Noise Emission (Acoustic): <65dBA when idle and when building.

- Air quality conditions must be free of excessive solid particulates (conductive or non-conductive) and airborne oils to prevent system damage.

Usage Features:

- Integrated Tool Changer: The F3300 features an integrated tool changer with capacity for four extruders, enhancing versatility and efficiency in material handling.

- Heated Material Bays: Four heated material bays ensure optimal material conditions for consistent print quality.

- Automatic Calibration: The printer includes automatic calibration capabilities, simplifying setup and ensuring accuracy.

- Large Touchscreen Graphical User Interface: A large touchscreen provides an intuitive and user-friendly interface for operation and monitoring.

- Internal Cameras: Two internal cameras allow for remote monitoring of the printing process, providing convenience and oversight.

- Software Integration: The printer is designed to work with GrabCAD Print and/or Insight software packages for preparing build files. A separate computer workstation is required for this purpose.

- Vibration Consideration: The F3300 printers are capable of generating vibrations depending on part build geometry and material characteristics. This should be considered when locating the printer near vibration-sensitive equipment.

Maintenance Features:

- Minimum Operational Clearances:

- Side Clearance: Minimum 91.4 cm (36 inches) on each side for proper air circulation and maintenance access.

- Rear Clearance: Minimum 91.4 cm (36 inches) for maintenance access and opening doors.

- Front Clearance: Minimum 127 cm (50 inches) for opening oven and electronics bay doors.

- Overhead Clearance: Minimum 50.8 cm (20 inches) for fully opening top hinged covers.

- Site Preparation Guide: The comprehensive guide provides detailed instructions for selecting an appropriate location, unpacking, and preliminary setup, including:

- Crate Inspection: Instructions to inspect the shipping crate for damage before opening.

- Required Tools: Lists basic hand tools, a utility knife, a forklift with specific fork length, a ladder, and requires two or more people for moving.

- Moving the Crated Printer: Emphasizes the need for a forklift or pallet jack due to the printer's weight (1724 kg / 3800 lbs) and provides designated lifting locations.

- Unpacking Procedures: Step-by-step instructions for removing crate panels, screws, protective bags, foam pieces, and shipping blocks, with warnings for careful handling.

- Stabilizing Foot Adjustment: Detailed steps for raising, lowering, and adjusting the printer's stabilizing feet to ensure stability.

- Internal Shipping Material Removal: Guidance on removing light tower, foot panels, cardboard, and shipping blocks from the gantry and oven enclosure.

- Electrical Service Connection: Instructions for routing the power cable and connecting wires to the line filter, emphasizing that a licensed electrician must perform all wiring and comply with electrical codes.

- Installation Checklist: A checklist summarizing electrical, environmental, and required installation tasks to ensure readiness.

The F3300 is delivered with a Welcome Kit containing documentation on how to download the user guide and common tools for printer maintenance. The design prioritizes ease of installation and ongoing serviceability through clear access points and detailed instructions.