Machine with or without thread trimmer:

The machine requires a needle position and depending on the sewing drive,

possibly also a reference position.

Reference position:

The reference position must be set in such a way, that the point of the

needle in direction of the insertion stitch closes with the right (inner) edge

of the needle slide plate.

Needle position (with stop in and outside the seam (Fig. 4)):

The needle position must be set in such a way, that when the machine is

stopped, the hook of the thread knife catches the thread loop lying over

the looper securely without touching the looper.

Notes for sewing drives which have two needle positions:

The above mentioned needle position is position 2 at the sewing drive.

It is essential that position 1 is set with consultation of the operating

instructions of the sewing drive

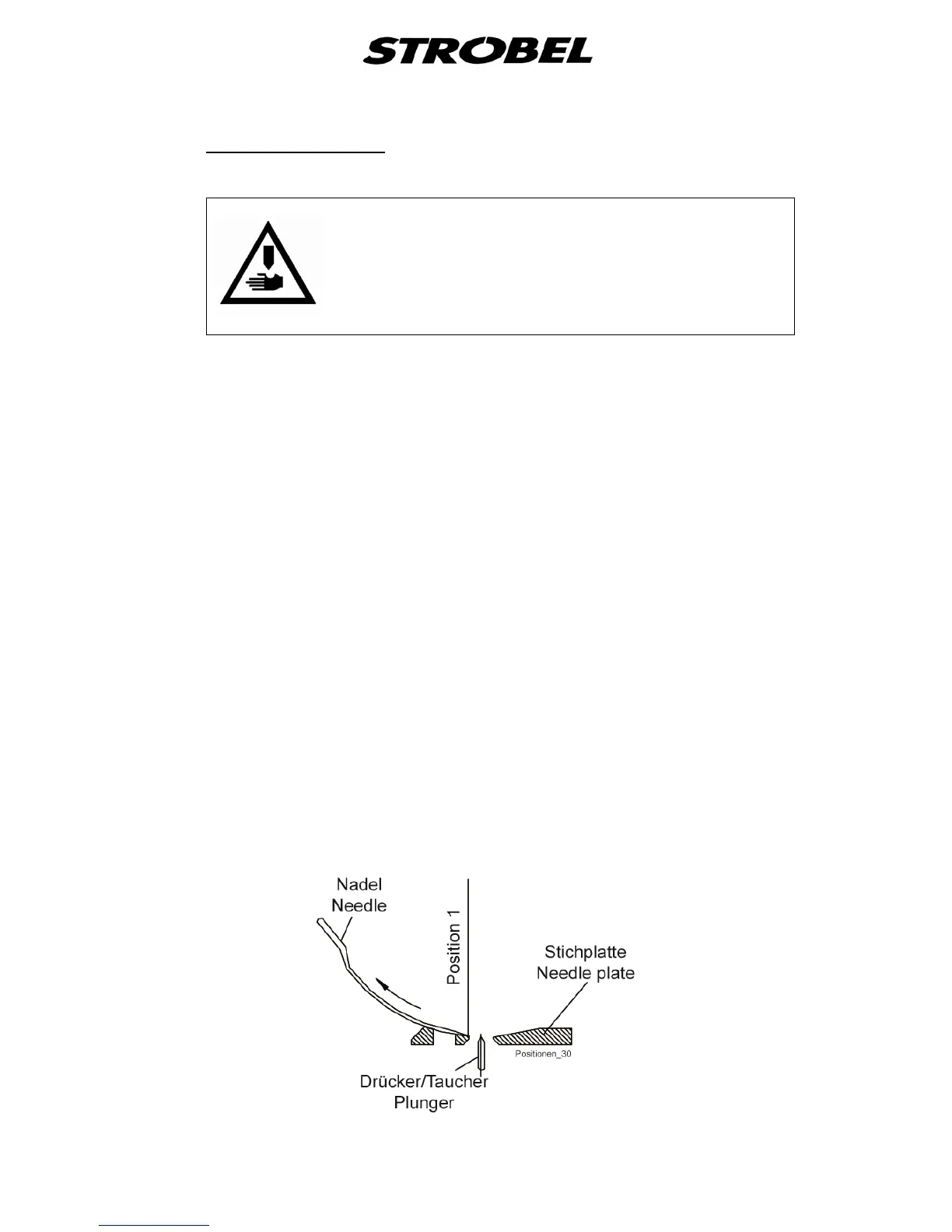

Needle position (when stopped within the stitch):

The needle position must be set so that the tip of the needle closes

against the right edge of the needle slide plate facing towards the outward

stitch.

At the same time, the thread loop lies under tension across the looper.

The needle position is position 1 at the sewing drive.

Fig. 6

Loading...

Loading...