34 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Roll seamer (Cl. VEB100-4)

Using the knurled screw (1) (Fig. 13b and Fig. 14b), the tilt angle of the roll

seamer towards the plunger can be set.

This influences the seam diagram (zigzag stitch). The needle can pierce the roll

more or less deeply.

This setting is the most important control together with the stitch depth

regulation during roll seaming.

The horizontal setting is done after loosening the screw (4) Fig. 14b. This is

necessary when the seamer is exchanged for a different one, or if the seam

diagram should be changed.

If the horizontal setting of the seamer was changed, the seamer tilt angle needs

to be corrected again afterwards as described above.

If the range for the knurled screw is exhausted, then the rough setting can be

redone after loosening the screw (2) (Fig. 13b and Fig. 14b. Afterwards, the

axle needs to be clamped again without lateral play. If necessary, the entire

bearing block with seamer can be slightly adjusted on the needle plate after

loosening the 3 screws (3) Fig. 14b.

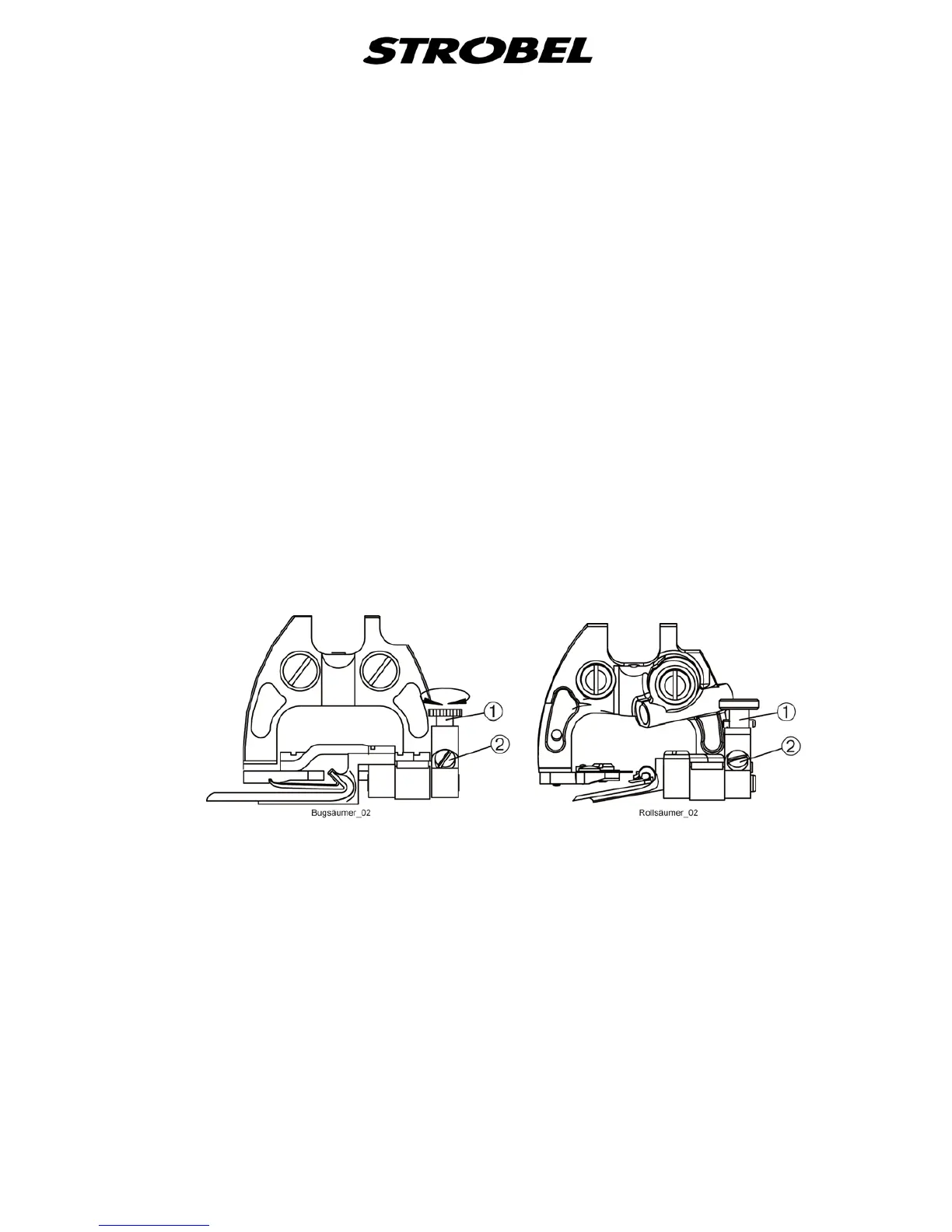

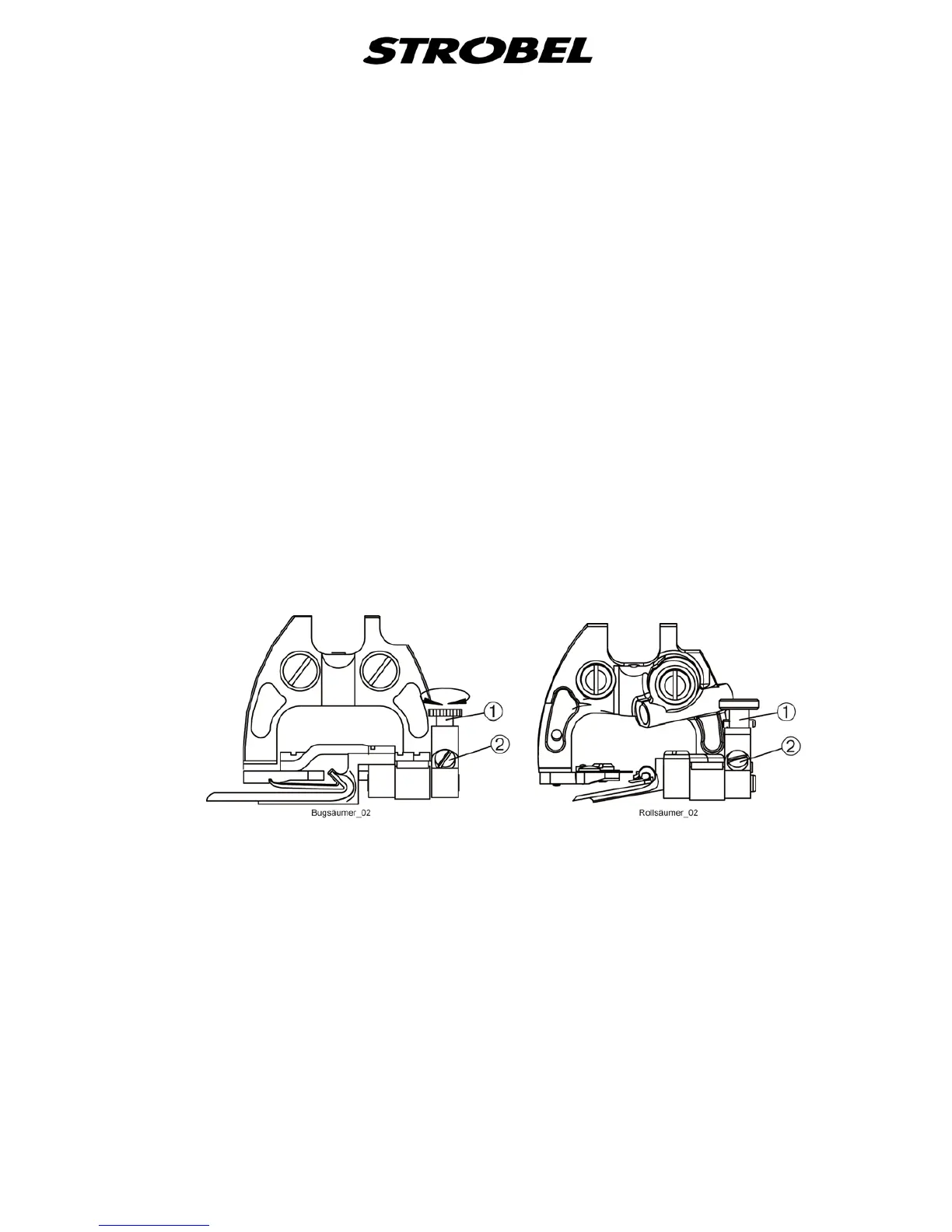

Fig. 13

a b

Cl. VEB100-5 Cl. VEB100-4

Loading...

Loading...