-13-

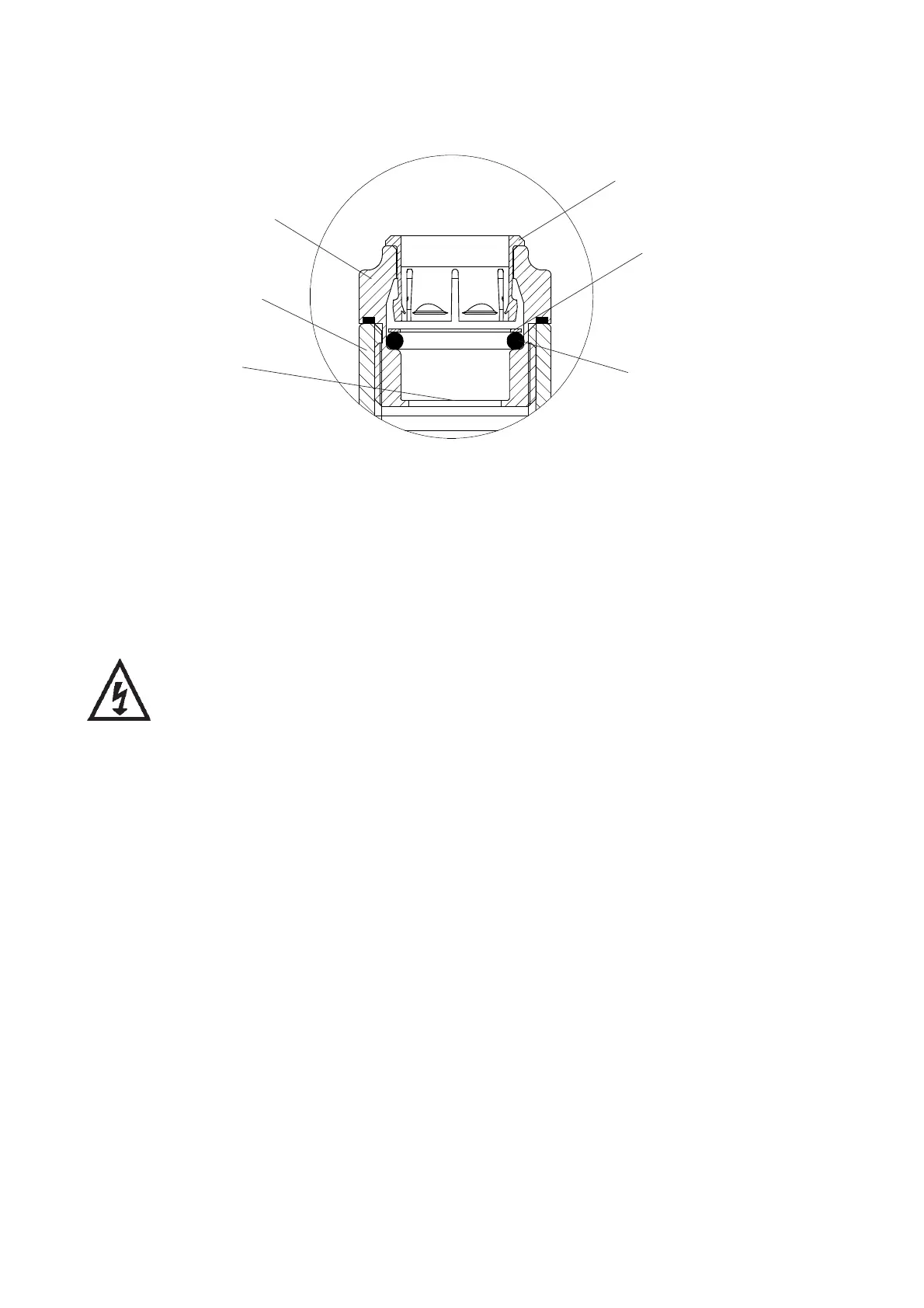

3. Check in the mouth of the fitting that 'O'-ring, nylon washer and collet are in position.

4. Push pipe firmly into the fitting, until pencil mark is level with the top of the collet and

the pipe stop resistance is felt. Pull on pipe to check it is secure and correctly fitted.

If you have any concern either about using push-in fittings or should the joint leak on

final test isolate the water supplies and contact Pump Assist on 0844 98 000 97.

ELECTRICAL INSTALLATION

WARNINGS:

The electrical installation must be carried out in accordance with the

current national electrical regulations and installed by a competent

person.

In the interests of electrical safety a 30 mA residual current device

(R.C.D.) should be installed in the supply circuit. This may be part of a

consumer unit or a separate unit. For submersible pump installations

this device MUST be installed.

Before starting work on the electrical installation ensure the power

supply is isolated.

This appliance must be earthed.

The motor and wiring must not be exposed to water.

Do not allow the supply cord to contact hot surfaces, including the

motor shell, pump body or pipework. The cord should be safely

routed and secured by cable clips.

The standard pumps are suitable for a supply of 230V, 1 Phase, 50Hz. Other voltages

(110V) and frequencies (60Hz) are available on certain models and it is therefore very

important to ensure the voltage and frequency on the pump rating plate matches the

supply.

When installing a 110V, 1 phase pump, it must be in accordance with the current

electrical regulations that apply to the installation.

The pumps are rated for continuous use with the exception of the 600 Boostamatic (see

technical specification for rating details).

Fig. 10

Collet

Washer

‘O’-Ring

Outlet

Fitting

Body

Pipe Stop

Loading...

Loading...