Section 5

OPERATION

17

5.1 GENERAL

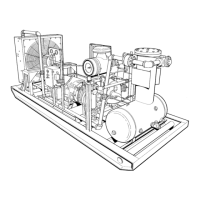

While Sullair has built into this compressor a com-

prehensive array of controls, protective devices

and indicators to assure you that it is operating

properly, you will want to recognize and interpret

the reading which will call for service or indicate the

beginning of a malfunction. Before starting your

Sullair compressor, read this section thoroughly

andfamiliarizeyourself withthecontrols, protective

devices and indicators - their purpose, location and

use.

5.2 PURPOSE OF CONTROLS

CONTROL OR INDICATOR PURPOSE

START PUSHBUTTON Depress to turn the compressor ON.

HOURMETER Records the cumulative hours of compressor opera-

tion; useful for planning and logging service sched-

ules.

LINE PRESSURE GAUGE Continually monitors service line air pressure. Located

on dry side of receiver downstream from check valve.

SUMP PRESSURE GAUGE Continually monitors receiver/sump pressure at vari-

ous load and/or unloaded conditions.

DISCHARGE TEMPERATURE GAUGE Monitors temperature of the air leaving the compres-

sor unit. The normal reading should be approximately

230ºF (110ºC ).

BEARING FLUID FILTER MAINTENANCE Indicates when a bearing fluid filter element change

INDICATOR is required. Shows red when the pressure drop

through the filter is excessive.

SEPARATOR MAINTENANCE INDICATOR Indicates when separator element change is required.

Shows red when the pressure drop through the sepa-

rator elements is excessive. The separators must be

replaced. DO NOT CLEAN.

FLUID LEVEL SIGHT GLASS Monitors fluidlevel in the sump. Proper levelis to fill the

sight glass.

FLUID RETURN LINE SIG HT GLASSES Used to indicate fluid flow in the return lines. When the

compressor is running at full load, fluid flow should be

visible in this sight glasses. There may be little or no

flow when the compressor is running unloaded, but a

sluggish flow at full load indicates a need to clean the

return line strainers.

FLUID STOP VALVE Cuts off flow of fluid to compressor unit at compressor

shutdown and allows flow of fluid to unit on start-up.

COMPRESSOR DISCHARGE CHECK VALVE Cuts off the reverse flow of air/fluid mixture through

compressor discharge system at compressor shut-

down.

THERMAL VALVE Regulates flow of fluid to and around the cooler. De-

signed to maintain an operating compressor discharge

temperature of 230ºF (110ºC ). Used for fast warmup

on start-up.

HIGH PRESSURE SHUTDOWN SWITCH Designed to shut down the compressor when thepres-

sure becomes too high. This switch is set for 365 psig

(25.2 bar).

PRESSURE RELIEF VALVE (Sump) Opens sump pressure to the atmosphere should pres-

sure inside the sump become too high (375 psig [25.9

bar]).

Loading...

Loading...