Section 6

MAINTENANCE

22

6. Scrape the old gasket material from the cover and

flange on the sump being careful not to let the

scraps fall in the sump.

7. Inspect the separator tank for rust, dirt, etc.

8. Reinsert the separator elements with gaskets at-

tached into the sump taking care not to dent them

against the tank opening. DO NOT remove gas-

ket staples. DO NOT use gasket sealer as it can

insulate thestaples, causing the element not to be

properly ground for insulation.

9.Clean the underside of the separator tank cover

and remove any rust.

10. Replace the cover plate, washers and capscrews.

Torque to 155 ft.-lbs. (210 Nm).

11. Reconnect all piping making sure the return line

tube extends to the bottom or 1/4” (6mm) above

the botton of the separator element. This will as-

sure proper fluid return flow to the compressor.

The return line should not contact the separator

element end cap.

12. Clean or replace fluid return line strainers.

13. Clean the fluid return line orifaces.

14. After assembly is complete, check for electrical

continuity between the separator flange and the

lid and tank flange with an ohmmeter.

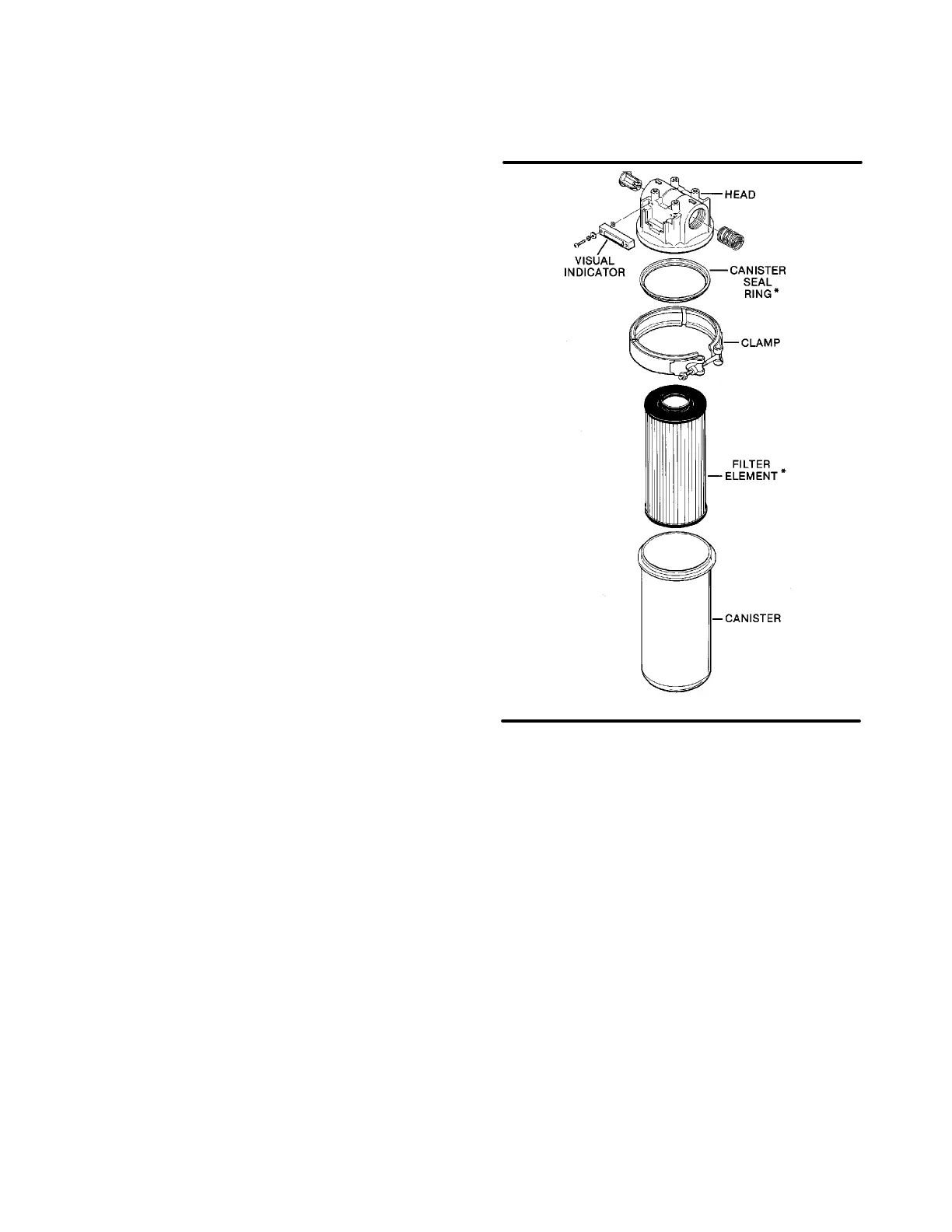

SERVICING THE BEARING FLUID FILTER

Refer to Figure 6-2. When a need for a fluid filter ele-

ment (P/N 250019-296) replacement is indicated by

the maintenance indicator located on the filter head

or at every fluid change, use the following instruc-

tions.

1. When servicing is required, the compressor sys-

tem must be shutdown to be sure nopositivepres-

sure remains on the lubricant in the filter.

2. To remove the canister, loosen band nut on the

band that holds canister to filter head, then gently

pull down canister. Filter element sits freely in

canister.

3. Remove filter element and gasket seal ring and

discard.

4. Installnew fluidfilter element in canister andinstall

the gasket seal ring to the canister flange.

5. Before reinstalling the canister to the filter head,

make sure mounting surfaceon filterhead isclean

and free of dirt.

6. Apply a film of fluid to the gasket seal ring andthen

install thecanister tothe filterhead. Reinstallband

and tighten band nut to 200 in.-lbs. (22.6 Nm).

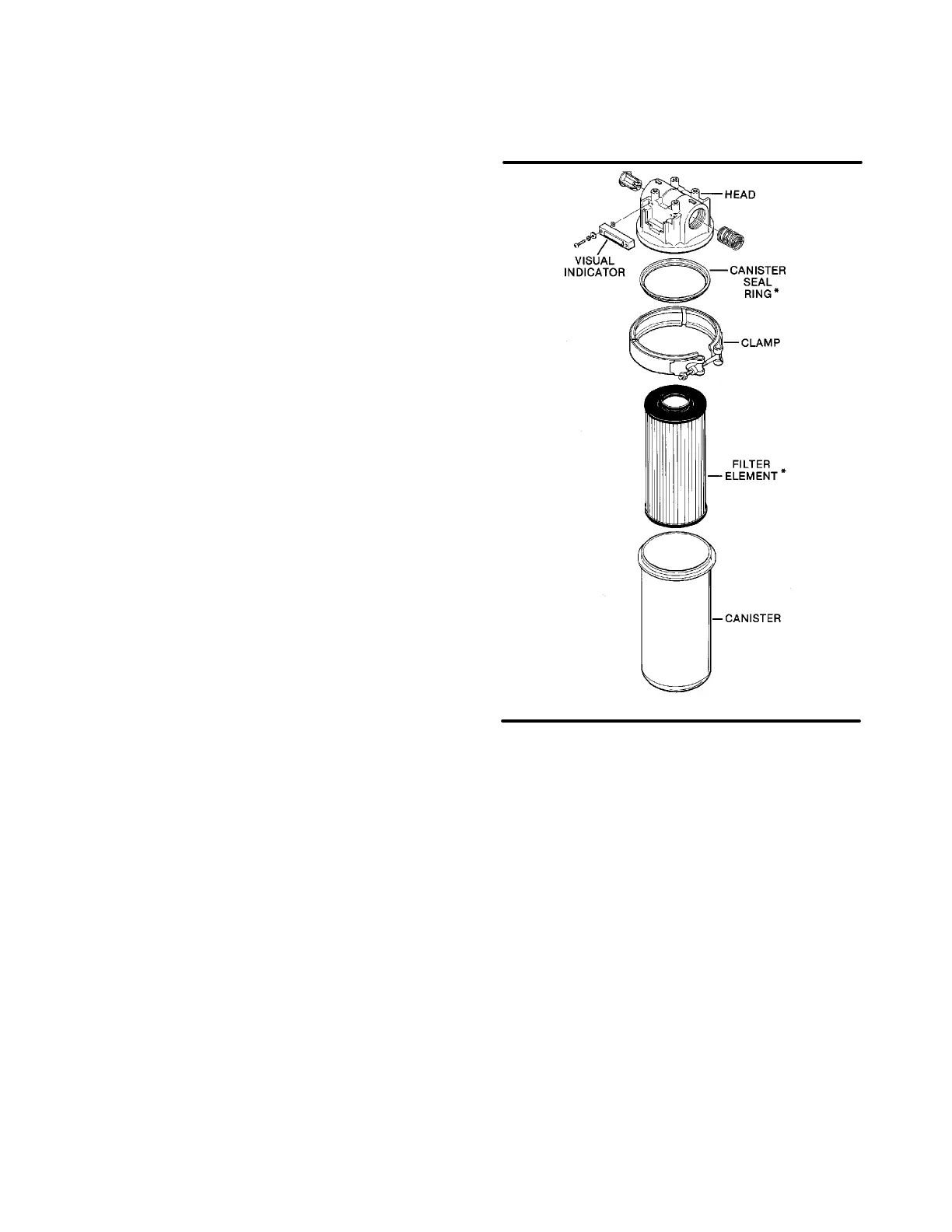

AIR FILTER MAINTENANCE

Refer to Figure 6-3. Air filter maintenance should be

performed when air filter restriction gauge reads 20

inches water column. The air filter is equipped with a

primary element and a secondary element. As pre-

viously stated, the restriction gauge will alert you as

to when the primary element maintenance is neces-

sary. When removing the primary element, always

check the secondary element for visible dirt, grease,

oil or damage. If any of these conditions exist, the

secondary element must be replaced at this time.

Otherwise the secondary element must be changed

after every sixth primary element inspection. The pri-

Figure 6-2 Bearing Filter (P/N 250019-296)

* Element Repair Kit P/N 602568-001

mary and secondary elements are designed for re-

placement only. DO NOT clean the elements.

ELEMENT REMOVAL

1. Clean the exterior of the air filter housing.

2. Remove the cover assembly by loosening the

wingnut securing it.

3. Pull the element assembly out of the housing.

4. Clean the interior of the housing by using a damp

cloth. DO NOT blow dirt out with compressed air.

5. Inspect the secondary element and replace if nec-

essary. This element is not cleanable.

6. To remove the secondary element, remove the

hex nut and sealing washer from the threaded rod

running through the element and pull the element

out of the housing.

7. Install the new secondary element and replace the

sealing washer and hex nut.

8. With the secondary element in place, replace the

primary element.

ELEMENT INSPECTION

1. Place abright light inside the element toinspectfor

damage or leak holes. Concentrated light will

shine through theelement anddisclose any holes.

Loading...

Loading...