68

375 John Deere Standard and Aftercooled/Filtered Operator’s Manual and Parts List

SECTION 5

The following steps apply to “H” and “HH” compressors

equipped with dual pressure controls.

Start the compressor and allow the engine to warm up 1.

to its normal operating temperature with the service

valve closed and the pressure selector valve set to the

LOW position.

Follow the procedure for setting the controls to 100 2.

psig (6.9 bar) rated full load pressure as describe in

preceding steps 2 through 6.

Turn the pressure selector valve to the HIGH position 3.

with the service valve closed.

Adjust the high pressure regulator so that the 4.

compressor maintains a receiver tank pressure of 165

psig (11.4 bar) on “H” models or 220 psig (15.2 bar) on

“HH” models.

Gradually open the service valve to atmosphere until 5.

the engine speed increases and the receiver tank

pressure stabilizes at 150 psig (10.3 bar) on “H”

models or 200 psig on “HH” models. At this point the

engine should be operating at its rated speed. If

necessary use the HI (+) or HI (-) buttons on the

speed control module to set the specied idle speed.

Bearing Lubrication (American Models)

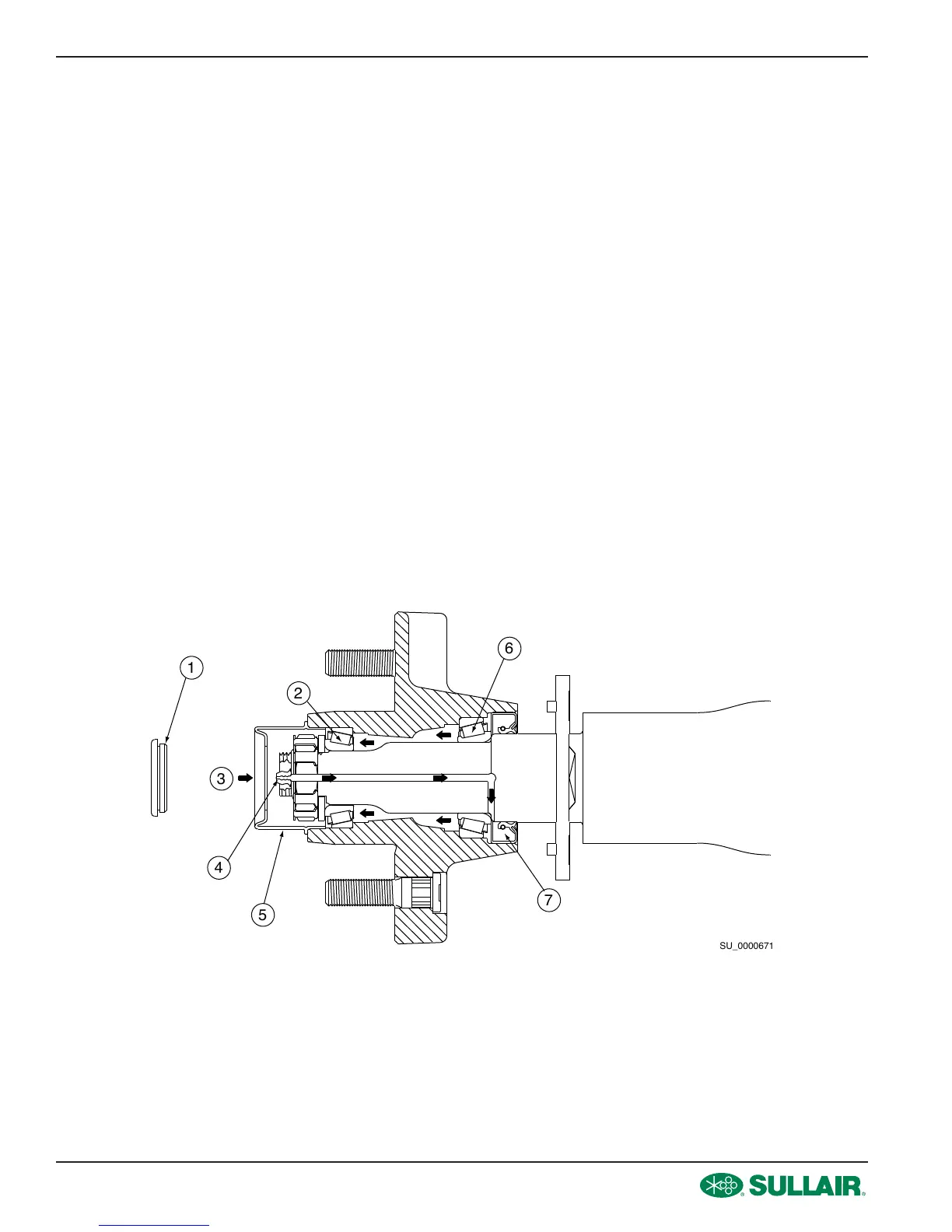

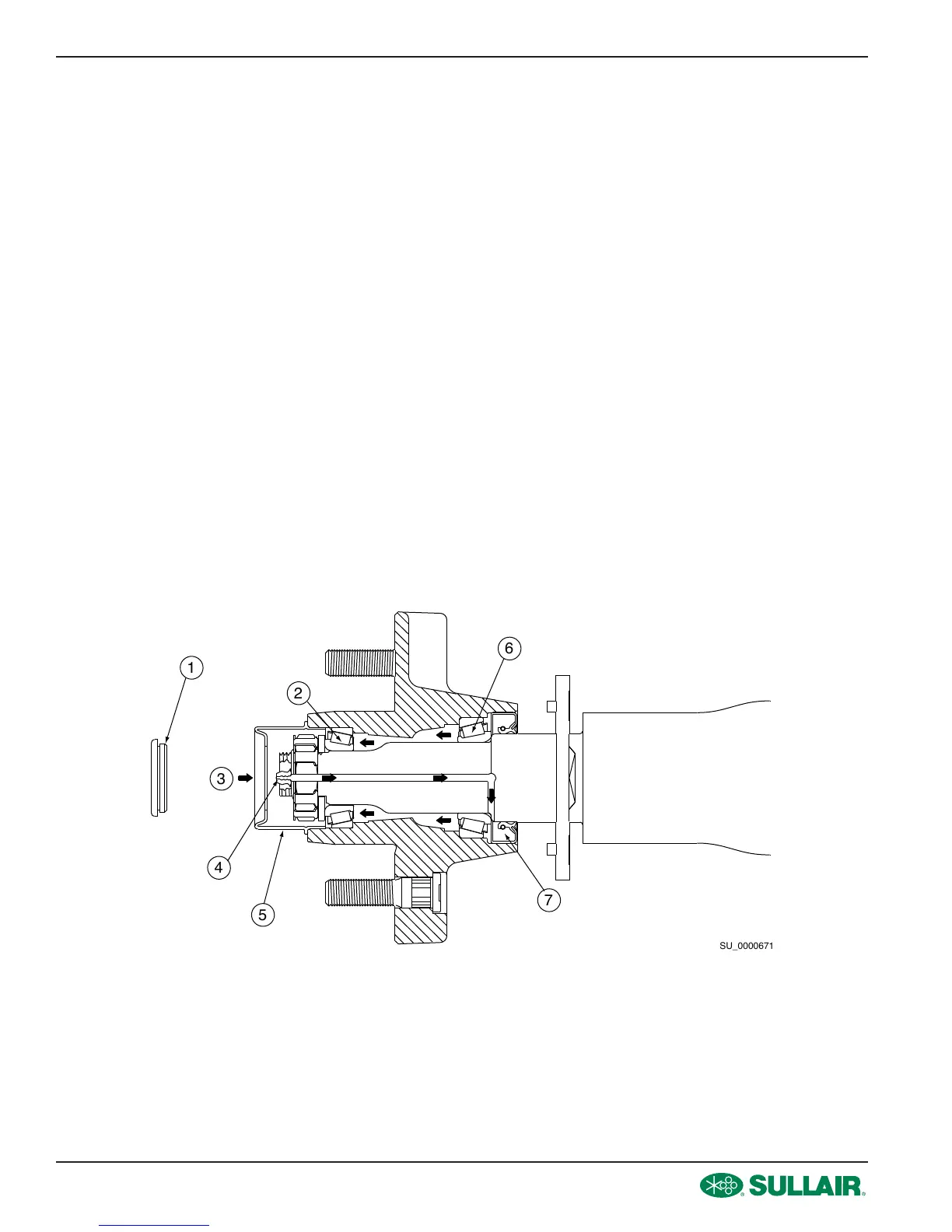

Refer to Figure 5-6. Proper lubrication of the portable

compressor’s bearing axle is critical to its proper function

and reduction of wear on this part. Wheel bearings should

be lubricated at least every 12 months, or more, to ensure

proper performance and minimize wear. Use a wheel

bearing grease that conforms to MILSPEC MIL-G-10924

or a high temperature one such as lithium complex NLGI

consistency #2.

Axles with the E-Z Lube feature can be periodically

lubricated without removing the hubs from the axle. This

feature consists of axle spindles that have been tted with

a grease zerk in their ends. When grease is pumped into

the zerk, it is channeled to the inner bearing and then

ows back to the outer bearing, and then back out of the

grease cap hold (see Figure 5-6).

Remove the rubber cap from the grease cap’s end.1.

Using a full charged grease gun, place the gun onto 2.

the grease zerk located on the end of the spindle.

Make sure the nozzle is fully engaged on the tting.

Pump grease into the zerk. The old grease will be 3.

displaced and ow out of the cap around the grease

gun nozzle.

When the new grease starts owing out of the cap, 4.

disengage the gun and wipe off any excess off the

cap; and replace the rubber plug.

Rubber Plug1.

Outer Bearing2.

Grease Flow3.

Grease Fitting4.

Metal End Cap5.

Inner Bearing6.

Spring Loaded Double Lip Seal7.

Figure 5-6: Typical E-Z Lube Axle

(American model shown)

Loading...

Loading...