Section 2

DESCRIPTION

6

Figure 2-2 Sullair Rotary Screw Air Compressor- Water-cooled Model

change of fluid is required, use only Sullair 24KT

fluid.

WARNING

!

Mixing of other lubricants within the compressor

unit will void all warranties!

Sullair recommends that a 24KT sample be taken at

the first filter change and sent to the factory for anal-

ysis. This is a free service. The sample kit with in-

structions and self--addressed container is to be

supplied by your Sullair dealer at start--up. The user

will receive an analysis report with recommenda-

tions.

Fluid is injected into the compressor unit in large

quantities and mixes directly with the air as the ro-

tors turn, compressing the air. The fluid flow has

three basic functions:

1. As coolant, it controls the rise of air temperature

normally associated with the heat of compres-

sion.

2. Seals the leakage paths between the rotors and

the stator and also between the rotors them-

selves.

3. Acts as a lubricating film between the rotors al-

lowing one rotor to directly drive the other , which

is an idler.

After the air/fluid mixture is discharged from the

compressor unit, the fluid is separated from the air.

At this time, the air flows through an aftercooler and

separator then to your service line while the fluid is

being cooled in preparation for reinjection.

2.4 COMPRESSOR COOLING AND LUBRICATION

SYSTEM, FUNCTIONAL DESCRIPTION

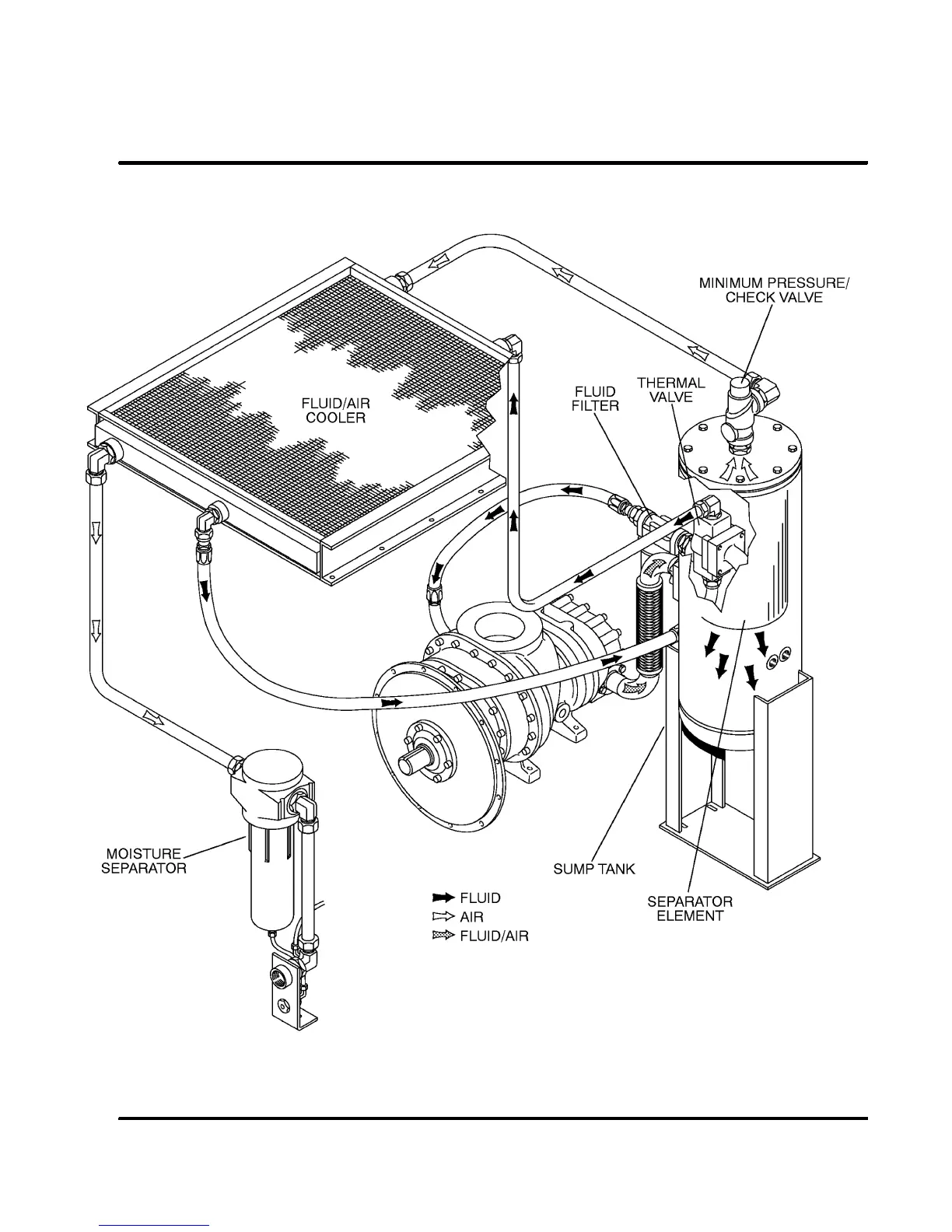

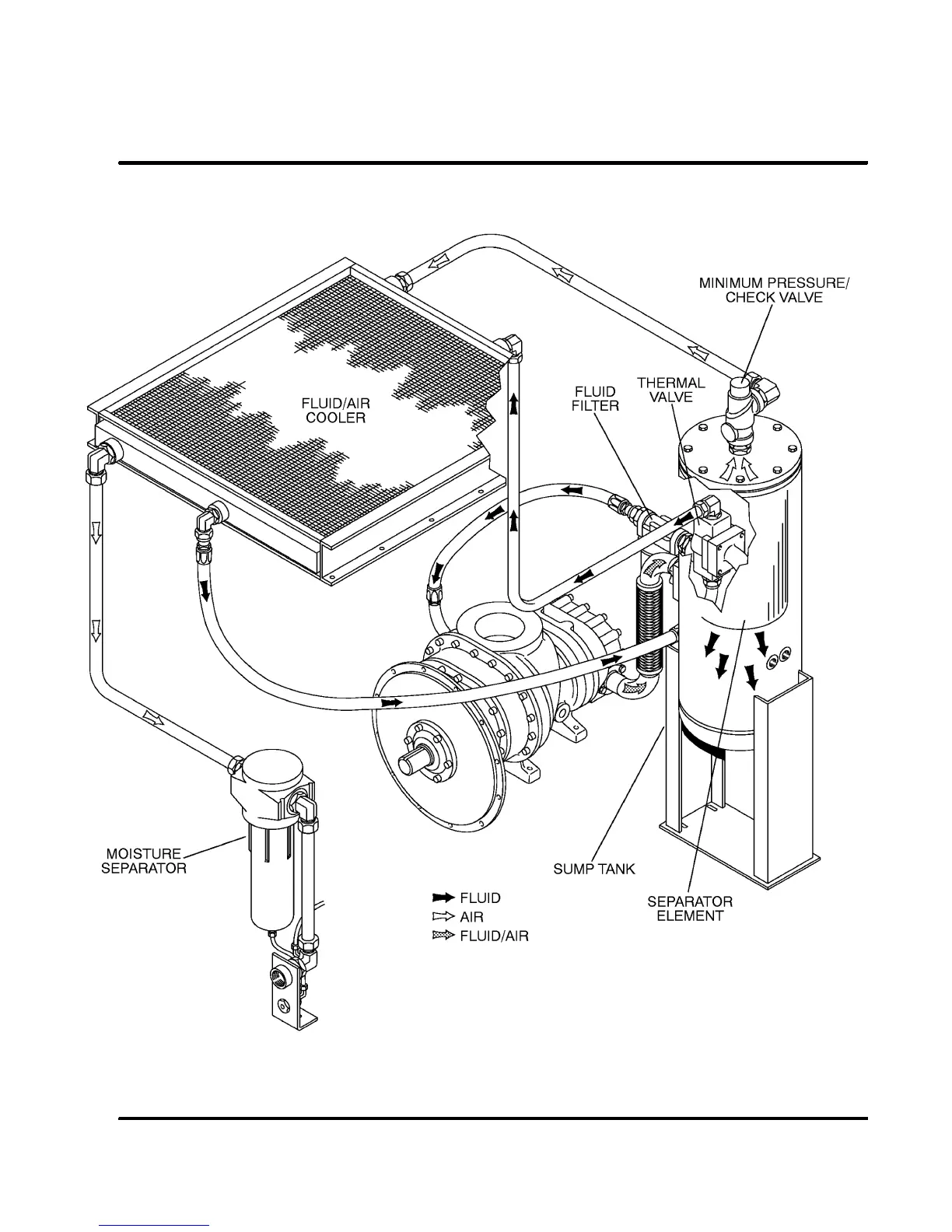

Refer t o F igur es 2 -- 3A and 2 -- 3B. T he C ooling and

Lubrication System (air--cooled version) consists of

a

fan

,

double shaft drive motor

,

radiator--type af-

tercooler

and

fluid cooler

,

full flow fluid filter

,

thermal valve

, and

interconnecting piping

and

tubing

. For water--cooled models, two

shell and

tube heat exchangers

and a

water--flow regulat -

ing valve

are substituted for the radiator--type cool-

er listed above.

The pressure in the receiver/sump causes fluid flow

by forcing the fluidfrom the highpressure area ofthe

sump to an area of lower pressure in the compres-

sor unit.

Loading...

Loading...