Section 5

19

PRINCIPLE OF OPERATION

PRINCIPLE OF OPERATION

The refrigerant circuit can be divided in 3 parts:

1. Low pressure section with an evaporator

(heat exchanger)

2. High pressure section including: Condenser,

liquid receiver, (if installed) and the filter

dryer.

3. Control circuit including: Compressor, meter-

ing device, hot gas by-pass valve (if

installed), fan pressure switch, safety high/

low pressure switch. Water cooled dryers are

equipped with a water flow control valve.

5.1 REFRIGERATION HEAT

EXCHANGER

1. There are two (2) basic sections, commonly

referred to as the high and low-pressure sec-

tions, in a refrigeration circuit. The high side

begins at the refrigerant compressor dis-

charge port and ends at the expansion

devise. The circuit leaving the expansion

devise through the air to refrigerant heat

exchanger and up to the compressor suction

port is known as the low pressure circuit. The

compressor takes in low pressure refrigerant

gas and compresses it to a high pressure

and high temperature gas. The high temper-

ature gas passes into the refrigerant con-

denser where it is cooled and liquefied. The

refrigerant then passes through the filter

dryer where moisture and any foreign parti-

cles are removed. The refrigerant then

passes through an expansion device where

the liquid refrigerant is throttled and a tem-

perature drop will occur as part of the liquid

turns into gas. The cold refrigerant gas and

liquid then enters the refrigerant-to-glycol

heat exchanger where it absorbs the heat

from the glycol as it evaporates. The low-

pressure refrigerant gas returns to the com-

pressor for repetition of the process.

2. Glycol Side: The thermal mass is food safe

and environmentally friendly polypropylene

glycol solution. It is pumped continuously

through the heat exchangers to eliminate

any dew point fluctuations commonly found

in other cycling dryers. The glycol is stored in

a stainless steel insulated tank with welded

connections. The glycol flows through the

pump to the Air-to-Glycol chamber located in

what is commonly termed as the heat

exchanger where it cools the compressed air

by counter flow. From there, it travels to the

evaporator where heat is extracted out by

the refrigerant. The heat saturated glycol

then returns to the storage tank. A tempera-

ture probe in the tank monitors the tempera-

ture and turns off the compressor when the

glycol reaches its set point. A float switch

inside the glycol tank shuts off the unit if the

glycol level drops below the minimum height.

3. Refrigerant controls: High-low refrigerant

cut-out switch senses high and low refriger-

ant pressure at refrigerant compressor inlet

and outlet ports shutting the compressor

down in the event of high refrigerant dis-

charge pressures or low refrigerant suction

pressure.

4. Liquid line filter dryer: Filters refrigerant of

moisture and any foreign particles. Must be

replaced if the refrigerant system has been

opened causing exposure to atmospheric

pressures.

5. Expansion device: Meters refrigerant flow in

the evaporator.

6. Electronic drain valve: An electronic drain

valve on the separator is designed to open

and close automatically to drain away con-

densate.

7. Crank case heater: A safety device which

prevents refrigerant migration back to the

compressor during shutdown.

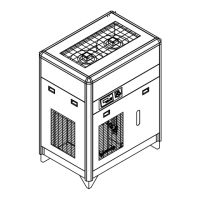

8. Air cooled models Cooling air flows from the

front to the back of the dryer. Air must be

drawn from a clean source in order to reduce

Loading...

Loading...