SECTION 5 PRINCIPLE OF OPERATION

21

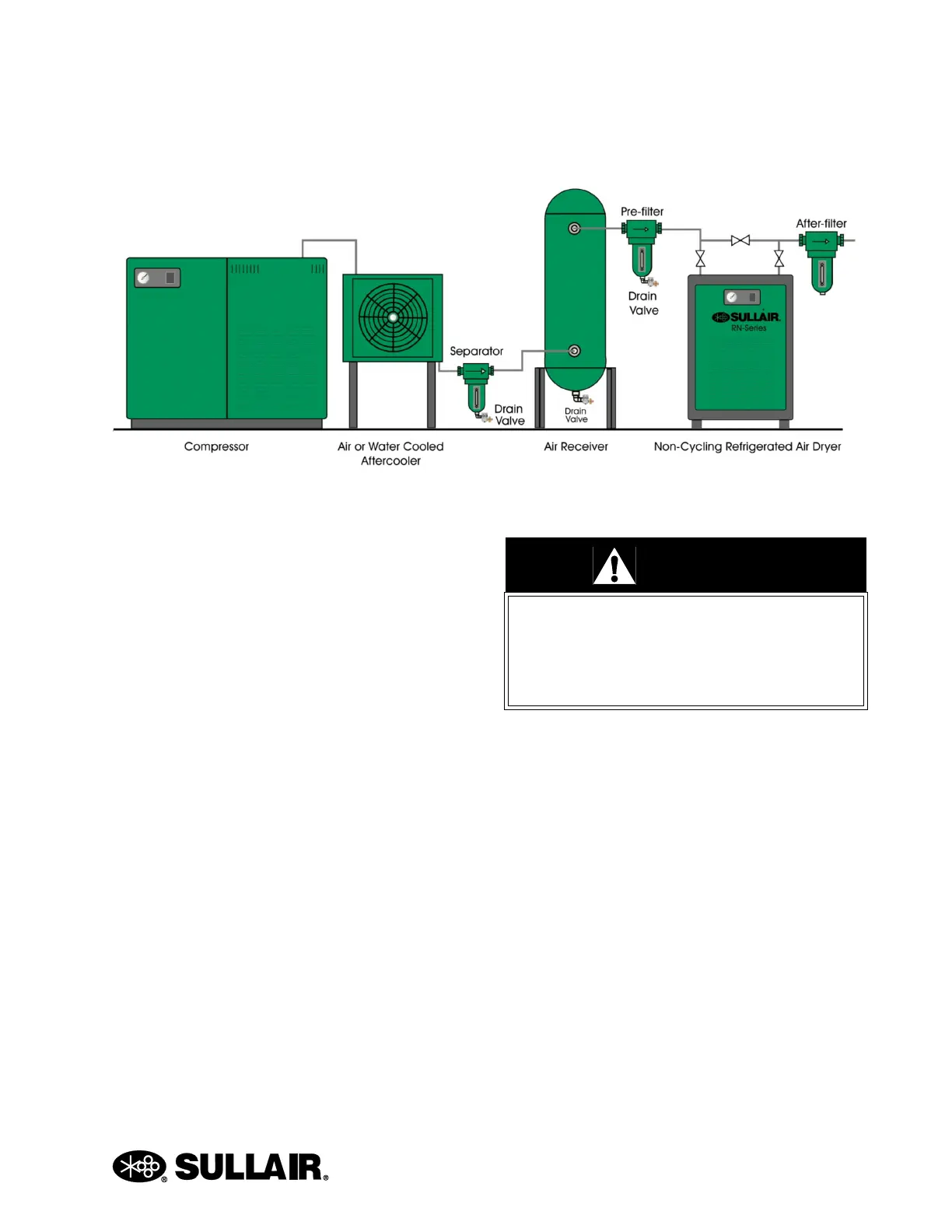

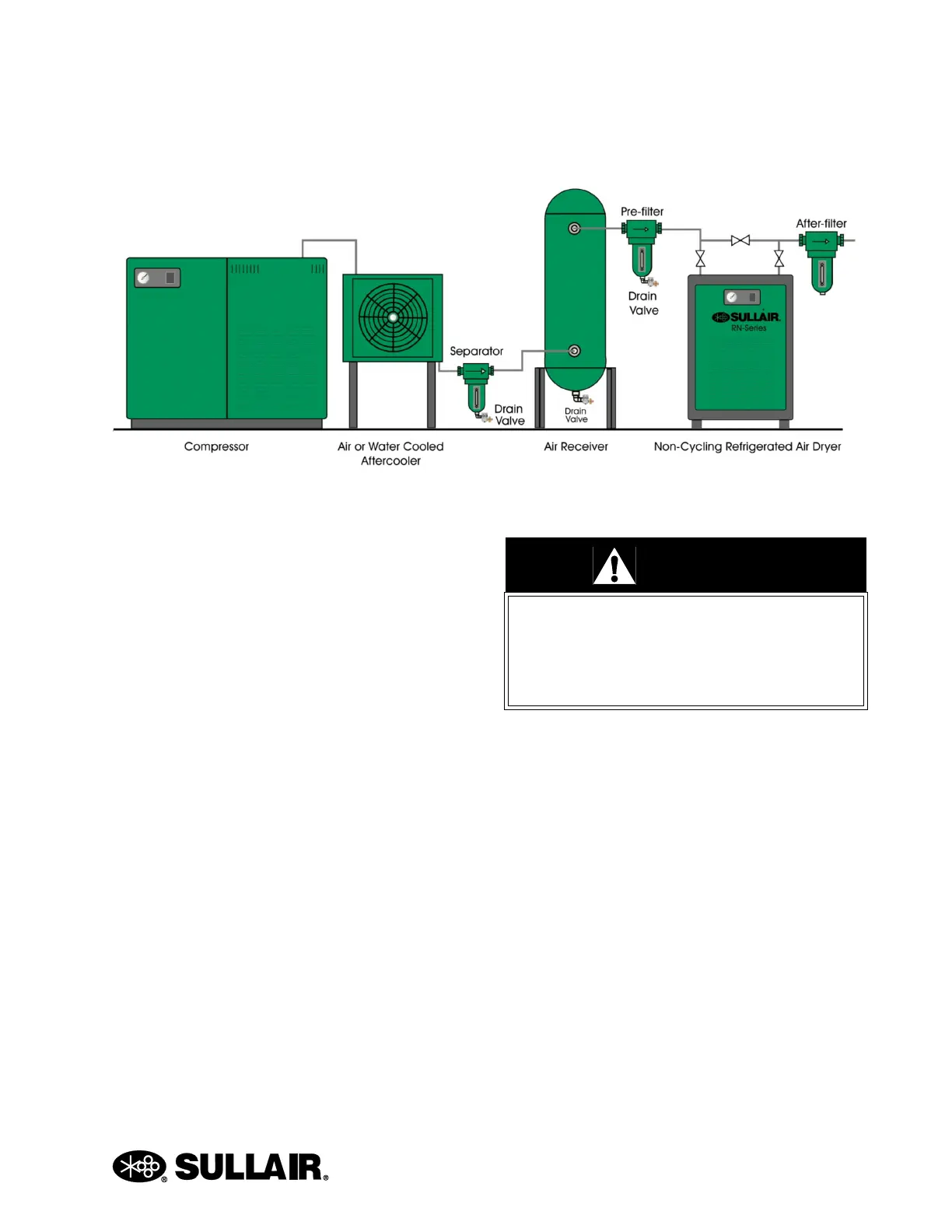

5.3 TYPICAL INSTALLATION

DIAGRAM

5.4 PIPE/CONNECTION

REQUIREMENTS

Refer to Section 3.2: Product Models and

Specifications.

5.5 ELECTRICAL CONNECTION

REQUIREMENTS

The owner shall furnish all labor, materials,

equipment and services necessary for and

reasonabaly incidental to complete the installation of

all electrical as shown on the drawings.

The electrical installation and connection shall be

made in strict accordance with the requirements of

any and all City, County, State or Federal codes of

Law having jurisdiction, the requirements and

recommendations of the Board of Fire Underwriters,

including all amendments and / or additions to the

said codes, laws, requirements, and

recommendations, the requirements and

recommendations of the local utility, the Owner, and

the Standard Building Code.

The installer shall obtain all permits and inspections

required for the work, and shall pay all costs and fees

thereof.

5.6 OPERATING PRECAUTIONS

This dryer has been thoroughly tested, packaged

and inspected prior to shipment. Nevertheless, the

unit could be damaged during transportation, check

the integrity of the dryer during first start-up and

monitor operation during the first hours of operation

Qualified personnel must perform the first start-up.

When installing and operating this equipment,

comply with all National Electrical Code and any

applicable federal, state and local codes.

Who is operating the unit is responsible for the

proper and safe operation of the dryer.

Never operate equipment with panels removed.

WARNING

Verify that the operating parameters match

with the nominal values stated on the data

nameplate of the dryer (voltage, frequency,

air pressure, air temperature, ambient tem-

perature, etc.).

Loading...

Loading...