INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 33

SECTION 6

6.2 SERVICE BULLETIN

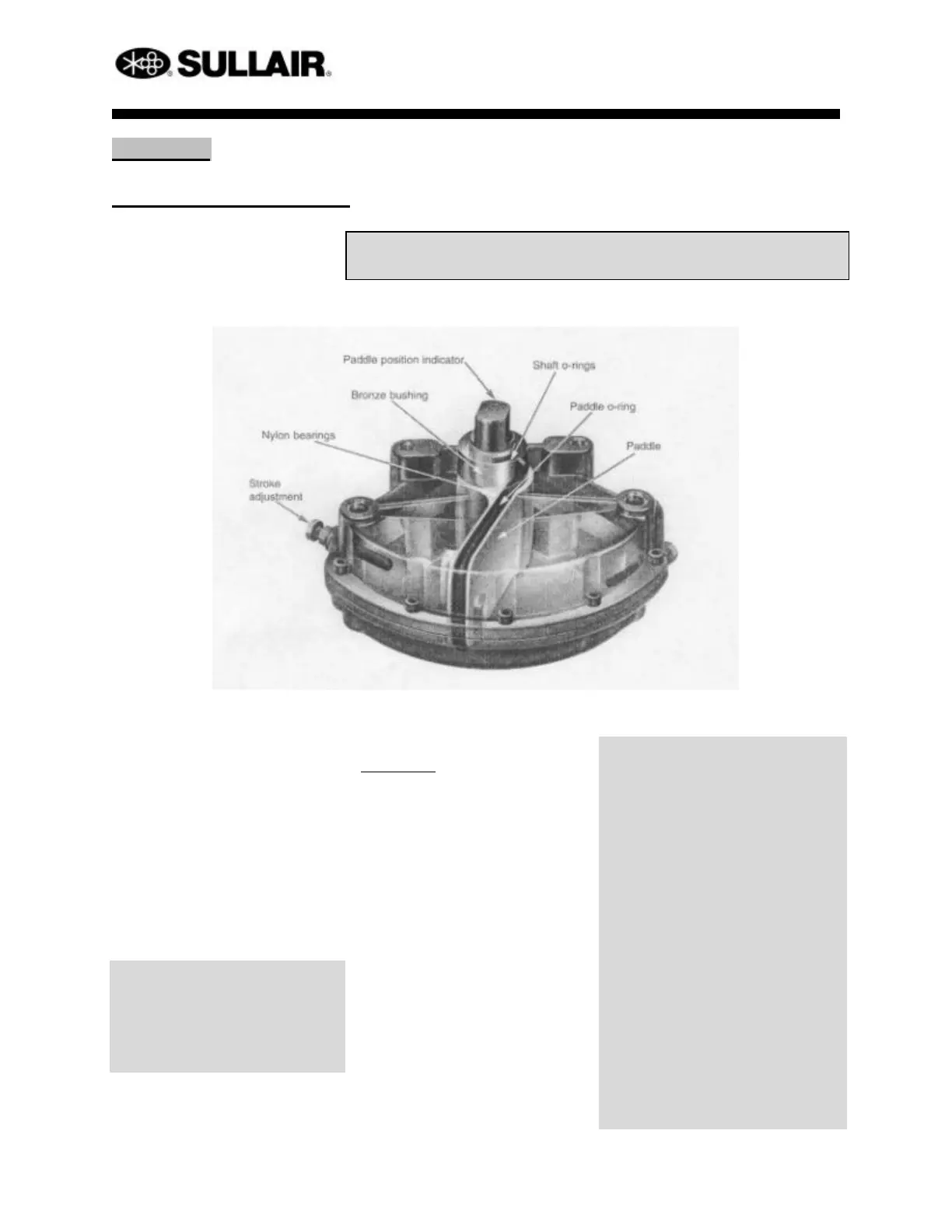

Vane Type Actuator

Installation, Operation & Service Instructions

Vane type actuators are compact 90°

rotary pneumatic devices to operate

quarter-turn valves.

They are designed for pressures

(supply and/or exhaust) up to 120

PSIG maximum.

WARNING !

Explosion. DO NOT EXCEED

PRESSURE RATINGS : excessive

pressure may rupture the actuator and

cause personal injury and/or property

damage.

Installation

1. Vane actuators are shipped from

the factory with an indicator line

stamped on the shaft ends which

shows the position of the vane

paddle. This indicator should be

used in determining the mounting

orientation of the actuator on the

valve.

2. Before mounting, the actuator and

the valve must be placed in the

same position (fully counter-

clockwise or fully clockwise).

Check the valve and actuator

mounting surfaces, bracket, stem

adapter and valve stem for proper

orientation and fit.

WARNING !

VALVE & ACTUATOR DAMAGE.

Once installed, leave at least 1-16 inch

axial clearance between the end of the

actuator shaft and the drive coupling

to prevent valve and actuator damage.

3. Use all mounting holes provided

on the actuator and assure a full

bolt diameter of thread

engagement into the actuator

housing as a minimum.

4. Tighten all bolts and nuts

uniformly, taking care to center

the actuator on the valve stem.

Loading...

Loading...