INSTALLATION, START-UP & MAINTENANCE MANUAL

MODEL NO.: SD-820 / SD-1710

REV 1 – AUGUST 03,.2001

Page 27

SECTION 5

5.2 CORRECTION FACTOR FOR INLET TEMPERATURE (Continued)

Example: To size for an inlet flow of 950 SCFM @ 105 F and 110 Psig.

1. Select models that produce at least 950 SCFM at 110 Psig. This case would

be the SD-1050 which can dry 1215 SCFM.

2. Multiply pressure corrected flow by the temperature correction factor to obtain

the flow of the dryer corrected for pressure and temperature:

1140 X (0.85) = 1008 SCFM

3. Confirm model selection. Model SD-1050 can flow 1008 SCFM at the inlet

conditions specified. The requirements of 950 SCFM is less, so model SD

1050 is correct.

5.3 PURGE ADJUSTMENT

To adjust the purge pressure, the following steps are to be followed, refer to the flow

schematics at the end of this manual:

1 The power is turned on, the dryer is operating.

2 When either chamber is depressurized and being regenerated, adjust

the pressure on the pressure gauge using the purge adjusting valve supplied.

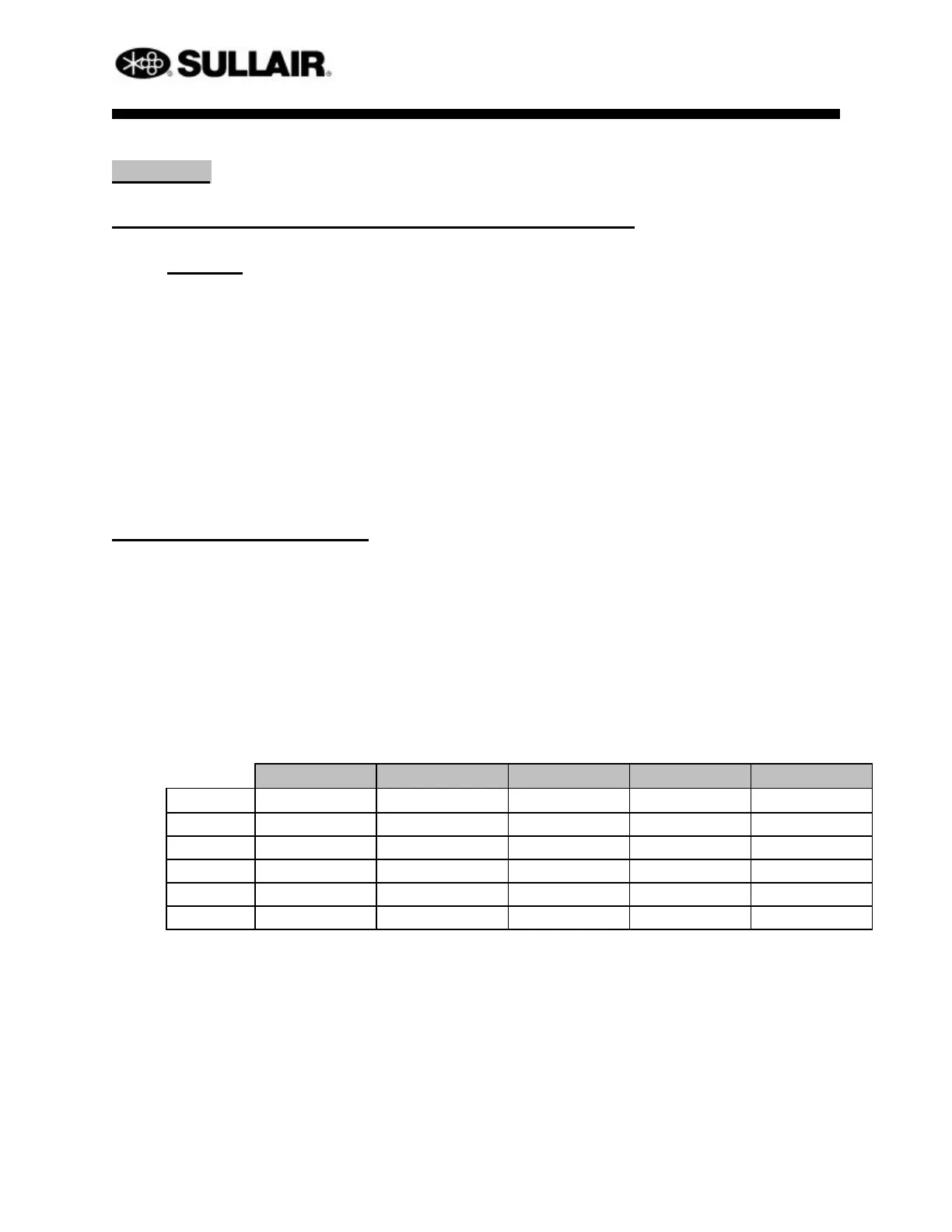

3 Refer to below table to adjust purge based on operating/inlet pressure.

SD-820 SD-1050 SD-1200 SD-1450 SD-1710

P1 P2 P2 P2 P2 P2

80 76 CF 80 74 80

90 80 90 82 78 82

100 81 90 82 81 85

110 81 97 82 77 82

120 CF 98 CF CF CF

CF = CONSULT FACTORY

P1 = Dryer inlet pressure (PSIG)

P2 = Dryer purge pressure (PSIG) based on dryer inlet temperature (100°F)

Loading...

Loading...