Section 3

SEQUENCING WITH VARIABLE

SPEED DRIVE COMPRESSORS

15

3. SEQUENCING WITH VARIABLE SPEED DRIVE COMPRESSORS

3.1 VARIABLE SPEED DRIVE APPLICATIONS

A multiple-compressor system can be designed using a variable-speed-drive (VSD)

compressor combined with other VSD compressors or fixed speed compressors. The

most efficient use of a VSD machine in sequencing is to set it up to always be the trim

machine and always running. This is accomplished using existing Sullair sequencing

logic as explained in the following sections.

3.2 SETUP FOR FIXED SPEED MACHINES AND A VSD COMPRESSOR

The fixed-speed machines in a mixed sequence system must always be set up for

load/unload operation. If controlled with Supervisor II Deluxe controllers, the pressure

regulator/s must be made to have no effect by setting the system to operate below the

effective range of the regulators. If controlled by the Supervisor Controller or WS

Controllers, the controls may be programmed for Load/No load operation. In this

configuration, the Full Load valve is energized any time the machine is running, thus

defeating modulation. Alternately, the Full Load solenoid valve may be rewired to the

Load output with any of the controllers (Supervisor Controller, Supervisor II Deluxe, or

WS) to achieve the same results. In all cases, care must be taken to not overload the

compressors by limiting operation to pressures within the capability of the drive motor.

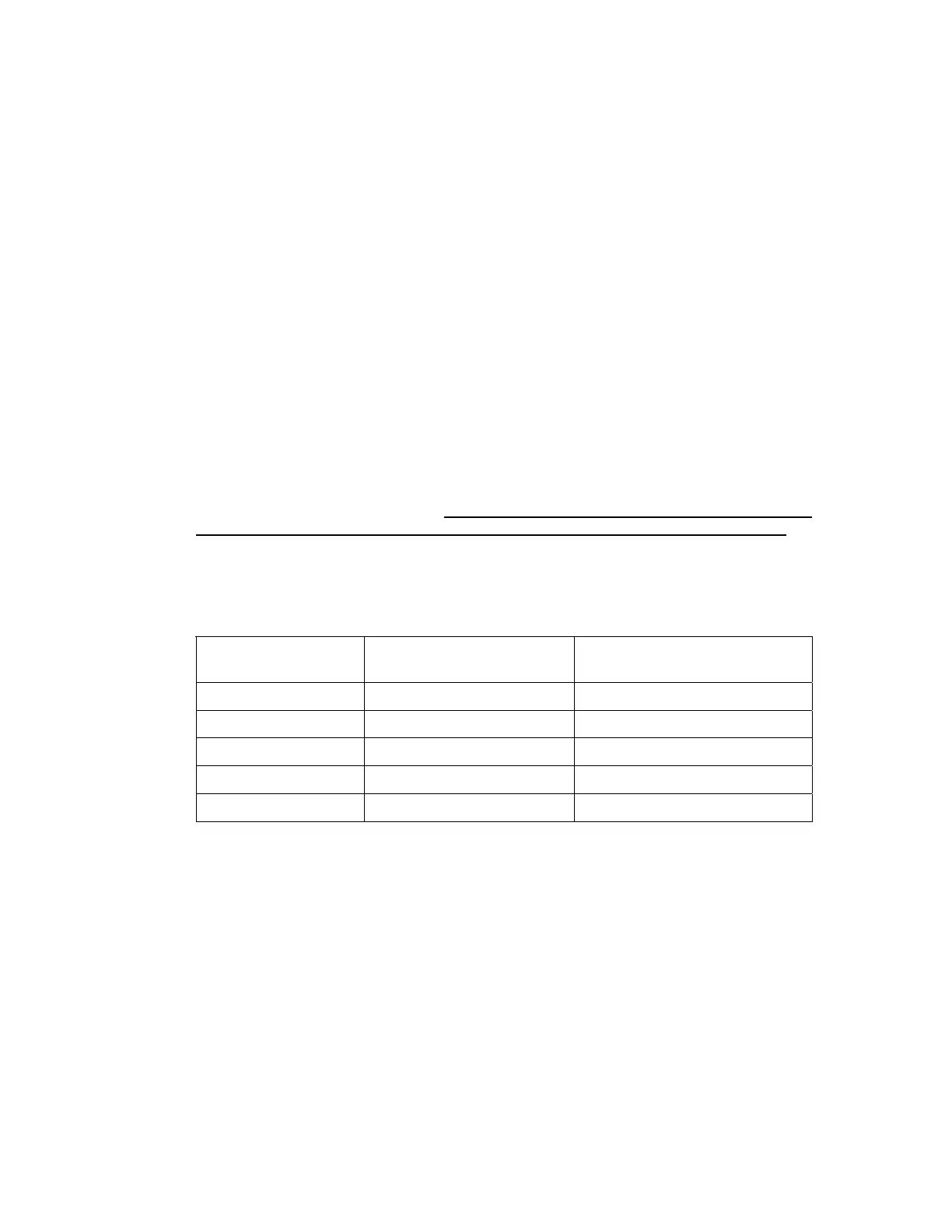

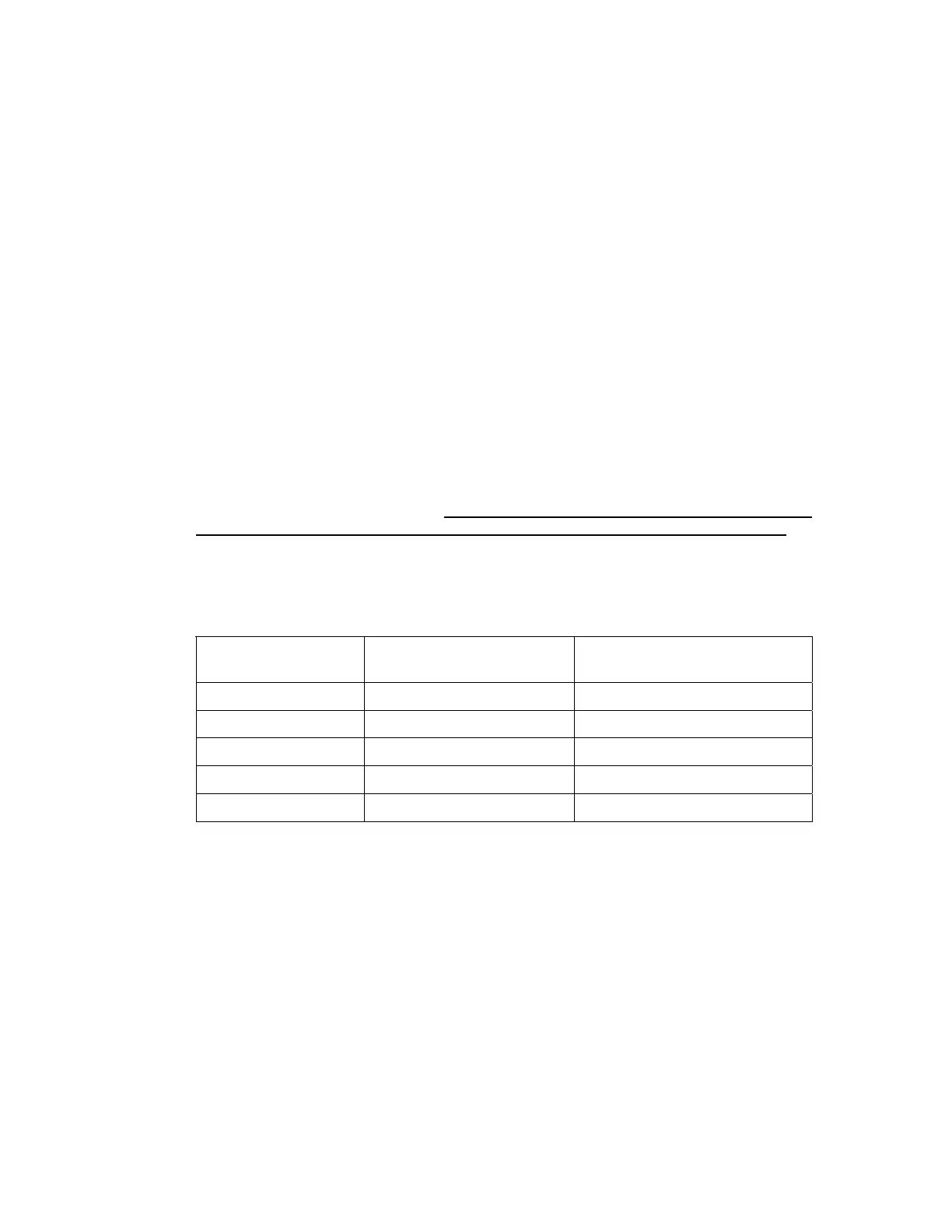

See Table 3.1 for suggested settings of compressors in a mixed sequence configuration.

These settings are typical for a target system pressure of 99 psi at discharge of

compressors.

Table 3.1 Mixed System Settings (Target Pressure: 99 psi)

Parameter VSD Compressor

Settings

Fixed-Speed Compressor(s)

Settings

Unload Setpoint 104 102

Load Delta 6 6

VSD Setpoint 99

Com # COM #1, 2 (, 3, 4, etc.)

Lowest Pressure 90

Since this machine is to always be the trim machine, no Full Load action is needed. The

Max Speed input signal should be disabled unless more than one VSD machine is in the

same sequence.

In this configuration, only the fixed-speed compressors are sequenced and the VSD

machine is run with its sequencing disabled. The Sequence hours mode can then be

used to automatically rotate the fixed-speed machines, or the fixed-speed machines may

be sequenced based on Com #.

Depending on the application and system demands, the VSD compressor can either be

run continuously or in the AUTO mode. This will allow the unload time to be minimize to

as low as an immediate stop on unload.

This arrangement sets the VSD machine to always restart at a higher pressure than the

fixed-speed machines thus forcing it to always operate as the trim machine. By adjusting

Loading...

Loading...