Section 5

SEQUENCING TIMERS FOR

EFFICIENT OPERATION

24

Machine Status

1 Trim

2 Stopped (Next machine in sequence)

3 Stopped

If the system pressure drops below the Sequence Load pressure (102) but is above the

Lowest Pressure (70), the next machine in sequence (2) will start and trim, and the

previously trimming machine (1) will go to full load after the Delay Start timer expires. If

the pressure is at 85 then the machine will start in about 1 minute as noted above.

Machine Status

1 Full Load

2 Trim

3 Stopped (Next machine in sequence)

If the system pressure stays below the Sequence Load pressure then the next machine

in sequence (3) will start after the Delay Start timer expires. If the pressure is at 85 then

the machine will start in about 1 minute as noted above.

Machine Status

1 Full Load

2 Full Load

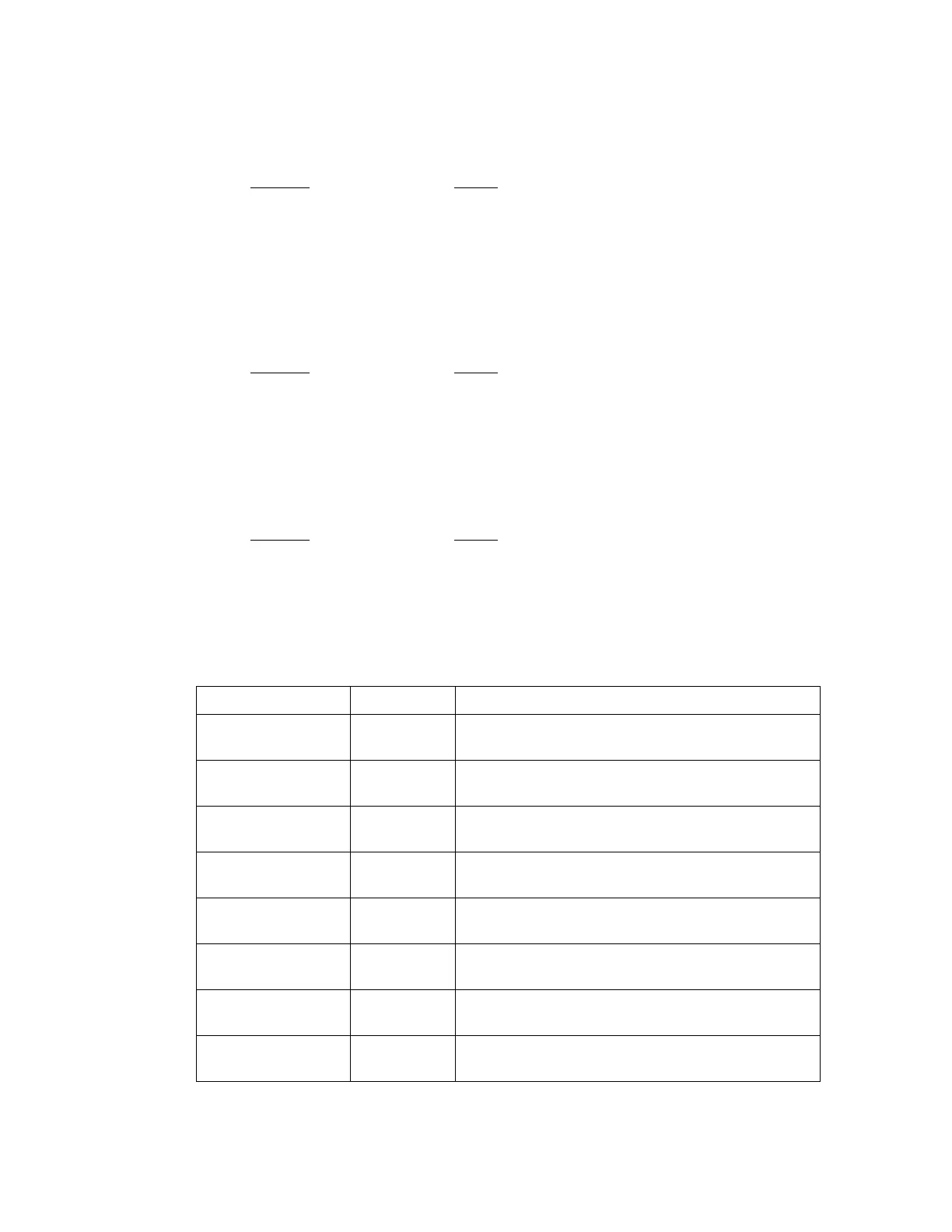

5.3 SEQUENCING TIMERS SUMMARY

Table 5.1 provides a summary of the sequencing timer operation described in the

preceding examples.

Table 5.1 Sequencing Timer Example Summary

EVENT PRESSURE SEQUENCE TIMER RESULT

Unload pressure 110 All machines unload above this pressure

regardless of Recovery timer

Recovery timer

active

108-110 Trim machine will unload after Recovery timer

expires

Sequencing unload

pressure

108 Trim machine unloads above this pressure,

Recovery timer starts

Sequencing load

pressure

102 Next machine in sequence loads below this

pressure, Recovery timer starts

Recovery timer

active

100-102 Next machine in sequence loads after Recovery

timer expires

Load pressure 100 All machines load below this pressure, Start Delay

timer starts

Start Delay Timer

active

70-99 Next machine in sequence starts after Start Delay

timer expires

Lowest Pressure 70 Next machine in sequence starts immediately

regardless of Start Delay timer

Loading...

Loading...