Section 7

MAINTENANCE

38

SEPARATOR ELEMENTS REPLACEMENT

Ref er to Figur e 7 --- 3 . The s epar ator el ements must

be changed when “Separator Maintenance Re-

quired” message is displayed, or once a year

whichever occurs first. Follow the procedure ex-

plained below for separator element replacement.

PROCEDURE FOR 200---300HP/150---225K W

ELEMENT REPLACEMENT

1. Relieve all pressure from the separator and all

compressor lines prior to disconnecting any

pipes, tubing, etc.

2. Disconnect all piping connected to the separator

cover to allow removal (return lines, service

lines, etc.).

3. Loosen and remove the twelve (12) #@4”x3”hex

head capscrews from the cover plate.

4. Lift the cover plate from the separator.

5. Remove the primary and secondary separator

elements.

6. Scrape the old gasket material from the cover

and flange on the sump being careful not to let

the scraps fall in the sump.

7. Inspect the separator tank for rust, dirt, etc.

8. Reinsert the separator elements with gaskets at-

tached into the sump taking care not to dent

them against the tank opening. DO NOT re-

move grounding staples. Check between sepa-

rator element flange and tank for continuity after

torquing bolts. DO NOT use anti---seize com-

pound on gaskets.

9. Clean the underside of the separator tank cover

and remove any rust.

10. Replace the cover plate, washers and

capscrews. Torque to 200 ft.---lbs. (271 Nm).

11. Reconnect all piping making sure return line

tubes extend to the bottom or !@4” (6mm) above

the bottom of the separator element. This will as-

sure proper fluid return flow to the compressor.

12. Check the return line strainer before restarting

the compressor (order replacement kit P/N

241772 if required).

PROCEDURE FOR 400---600HP/300---450K W

ELEMENT REPLACEMENT

1. Relieve all pressure from the separator and all

compressor lines prior to disconnecting any

pipes, tubing, etc.

2. Loosen and remove the twelve (12) #@4”x3”hex

head capscrews from the cover plate.

3. Lift the cover plate from the separator.

4. Loosen and remove the twelve (12) nuts and

washers from the retaining ring studs and re-

move the retaining ring.

5. Remove the gasket, and primary and secondary

separator elements.

6. Scrape the old gasket material from the retaining

ring and flange on the sump being careful not to

let the scraps fall in the sump.

7. Inspect the separator tank for rust, dirt, etc.

8. Reinsert the replacement separator elements

into the sump taking care not to dent them

against the tank opening. Reinsert retaining

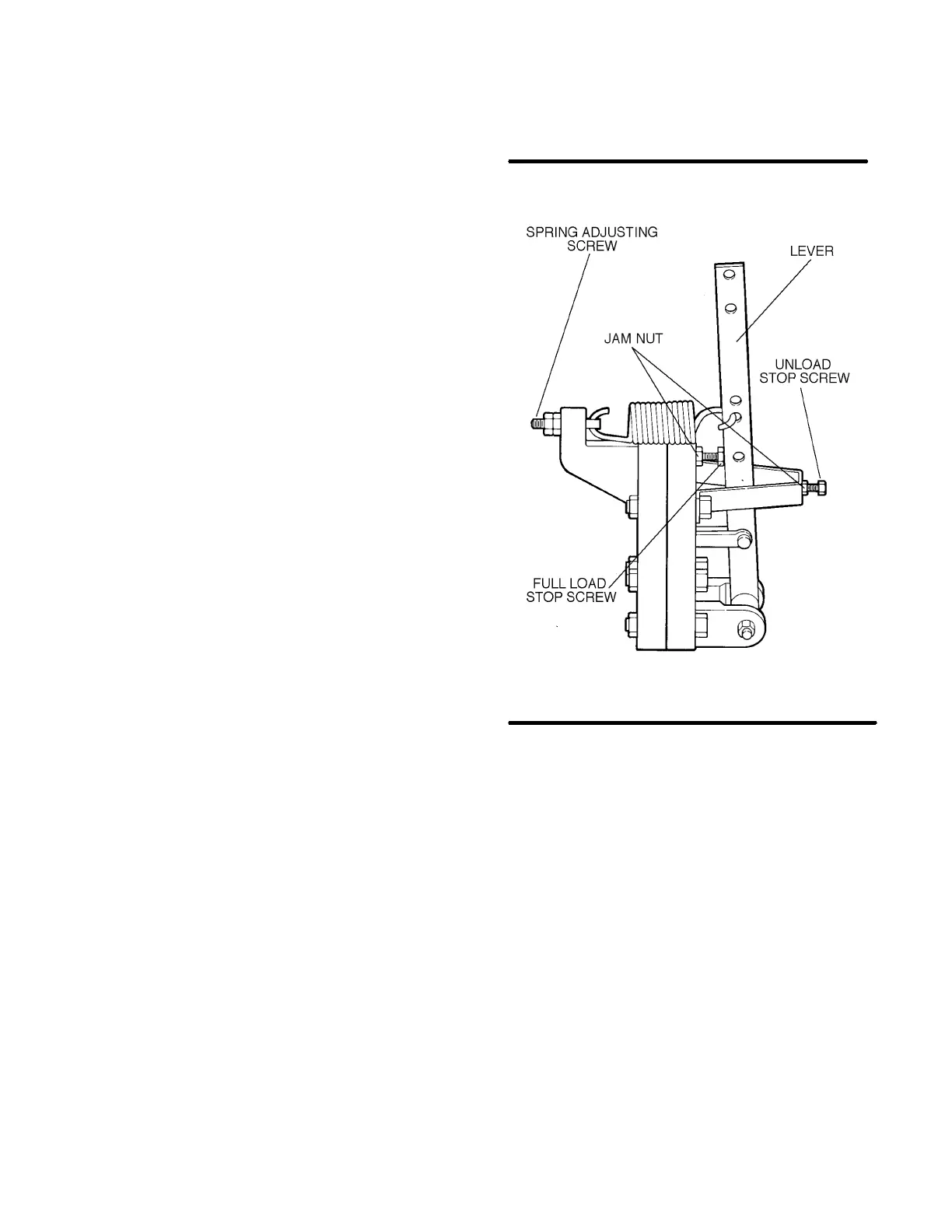

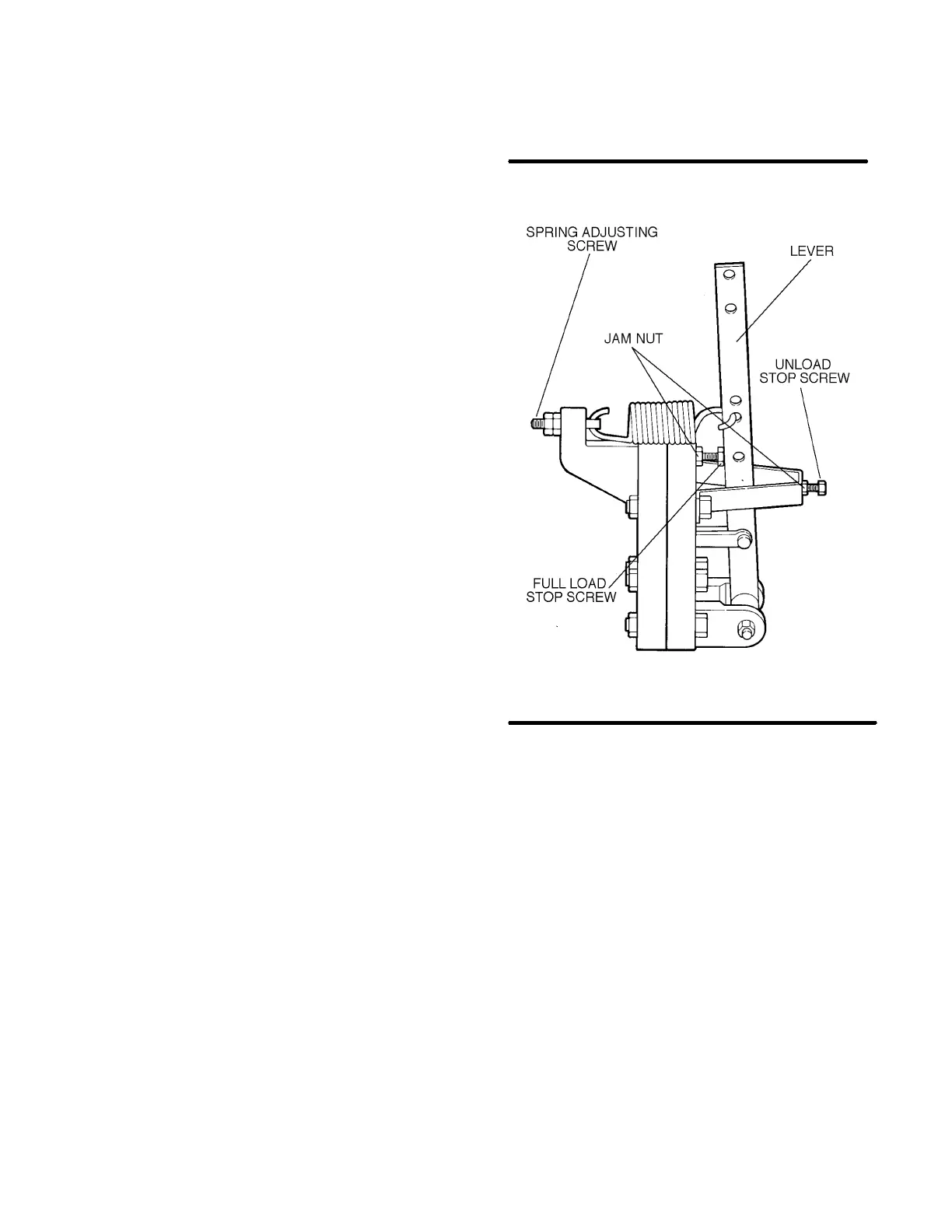

Figure 7---4 Sullicon Control (P/N 011682 ---003)

* Repair Kit P/N 250020---353

ring, washers and nuts and resecure. Torque to

30 ft.---lbs. (41 Nm). Check between separator

element flange and tank for continuity after

torquing bolts. DO NOT use anti---seize com-

pound on gaskets.

9. Clean the underside of the separator tank cover

and remove any rust.

10. Replace the cover plate, washers and

capscrews. Torque to 200 ft.---lbs. (271 Nm).

11. Reconnect all piping making sure return line

tubes extend to the bottom or !@4” (6mm) above

the bottom of the separator element. This will as-

sure proper fluid return flow to the compressor.

12. Check the return line strainer before restarting

the compressor (order replacement kit P/N

241772 if required).

CONTROL SYSTEM ADJUSTMENT

Refer to Figure 7 --- 4. Before starting the c ompres -

sor, but with power applied, press the PROG pad

on the Supervisor panel three times to enter the

PROGRAMMING mode. Continue pressing the

PROG pad until “MAX PRESS P2A” is displayed.

Use the cursor (UP arrow) pad to set the desired

Loading...

Loading...