SECTION 6 TS32 USER MANUAL

73

SHAFT COUPLING MAINTENANCE

The compressor unit and motor are rigidly connected

through the mounting adapter housing. This

arrangement makes coupling alignment

unnecessary. The coupling is a jaw type in shear. If

the elastomeric (rubber) element requires

replacement due to wear or damage, order a

replacement element and perform the following

steps:

1. Remove the coupling guard.

2. Loosen the retaining screw located on the

outer sleeve. Slide the sleeve to one side,

exposing the coupling element.

3. Unwrap the coupling element from the

coupling jaws.

4. Position the motor and compressor keyways

180 degrees apart

5. Install the new element by wrapping it

around the jaws, engaging the cogs on the

element into the jaws.

6. Reinstall the outer sleeve and secure by

tightening the two screws to 45 in·lbs (5 Nm).

7. Reinstall the coupling guard.

6.7 DRIVE COUPLING

INSTALLATION AND

ALIGNMENT

Refer to Figure 6-7 and Figure 6-8.

For installation and alignment of the drive coupling,

follow the steps explained below.

STEP 1 MOUNT HUBS

Mount the motor hub and the compressor hub onto

respective shaft. Position the hubs to establish the

correct gap specified in Table 6-1. Secure each hub

with a setscrew.

STEP 2 OFFSET ALIGNMENT

Clean any oil, grease, dirt or paint from coupling

faces and the other surfaces of the drive flanges.

Rotate shafts so that a straight edge will rest

squarely (or within the 0.010 inch maximum limit

shown in Table 6-1) on both flanges and at a point

90° away. The vertical offset alignment is adjusted by

the addition or removal of motor mounting shims.

Loosen the motor mounting bolts and slide the motor

sideways to correct the horizontal offset.

STEP 3 COUPLING GAP AND ANGULAR

ALIGNMENT

Position the hubs to establish the proper gap and

angular alignment as indicated in Table 6-1. To

determine the angular misalignment in inches,

measure the maximum space between the hub

flanges and the minimum space 180° away, and then

subtract. To adjust the horizontal angular

misalignment, loosen the motor mounting bolts and

adjust the motor position until the angular alignment

is within tolerance.When within the limits specified in

WARNING

Disconnect all power at source, before

attempting maintenance or adjustments.

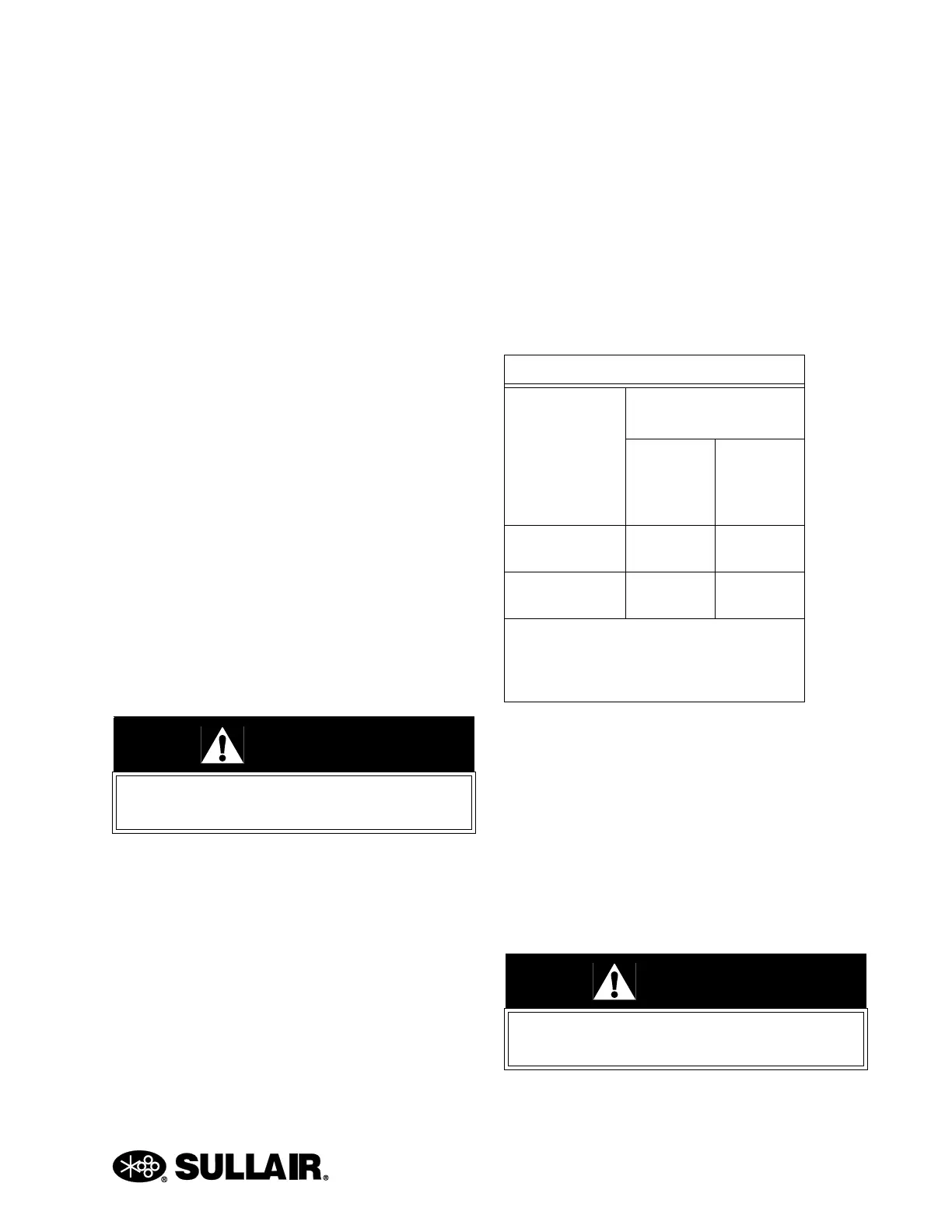

Table 6-1: INSTALLATION DATA

Coupling Gap

inches/mm

Max. Operating

Misalignment

Parallel

Offset

inches/

mm

Angular

inches/

mm (I)

.188

+/- .020 in.

.010 in. .010 in.

4.77

+/- .50 mm

.25 mm .25 mm

(I) Angular misalignment in inches equals

maximum A minus minimum B as shown in

Figure 6-7. DO NOT exceed values in Table

above.

WARNING

Disconnect all power at source, before

attempting maintenance or adjustments.

Loading...

Loading...