22

COMMON

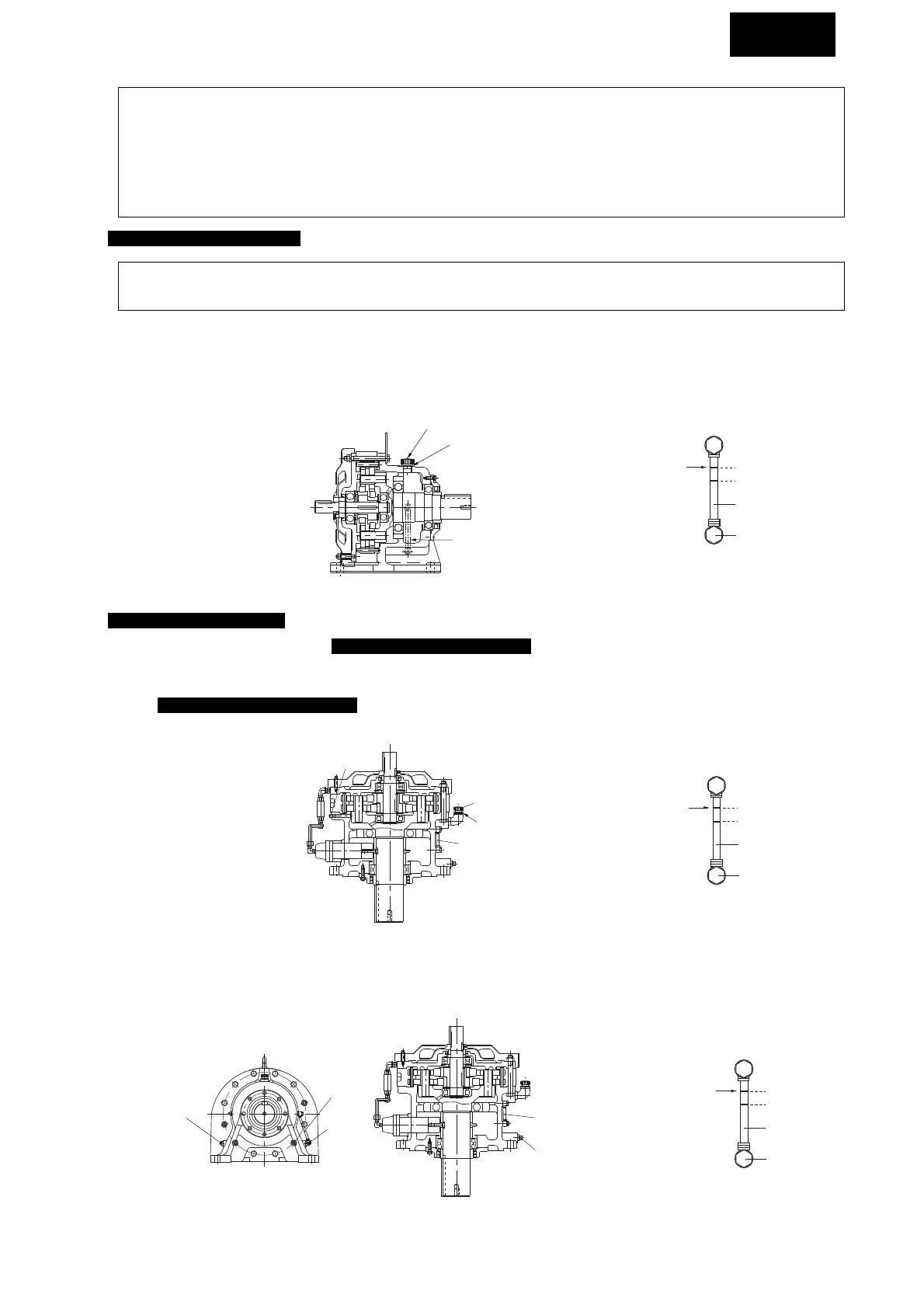

Oil supply for Horizontal Type (Refer to Fig.15)

• The standard location of the oil gauge on a horizontal unit is on the right side (viewed from the slow speed shaft side).

However, since the oil gauge may be placed on either side, select the side most convenient for observation.

1 Remove the oil filler plug.

2 Fill oil through oil filler port while checking oil level by the oil gauge.

3 Fill oil the upper line on the oil gauge.

4 Replace the oil filler plug.

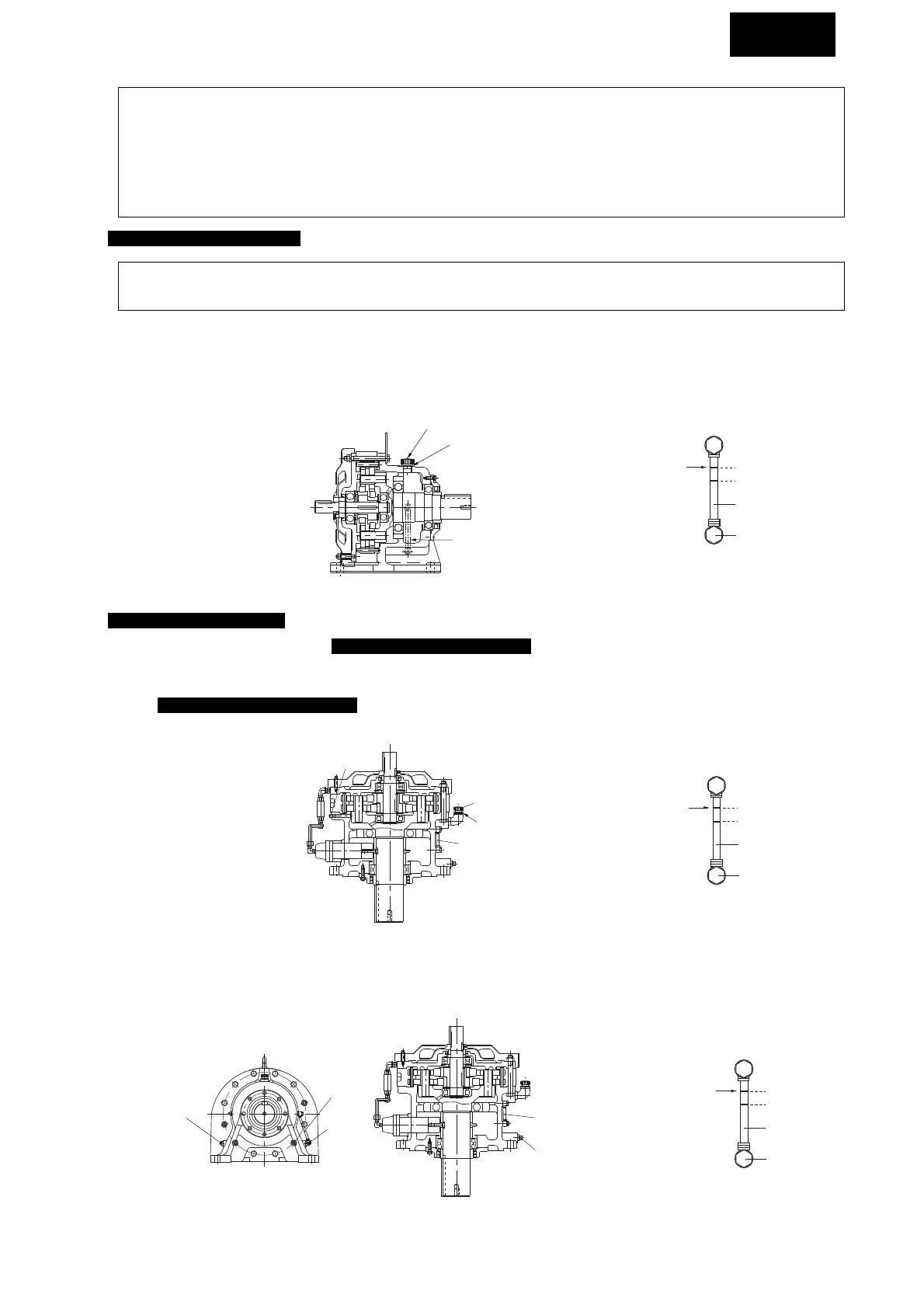

Oil supply for Vertical Type (Refer to Fig.16)

1 Remove the oil filler plug and, except for sizes 6255 and 6265 , also remove the airvent.

2 Fill oil through oil filler port while checking oil level by the oil gauge.

3 Fill oil the upper line on the oil gauge.

4 Except for Sizes 6255 and 6265 , apply water proof sealing tape to threads of the air vent plug before re-installing.

5 Replace the oil filler plug.

Fig. 15

Fig. 16

(4) Oil Supply

• Be sure to fill with oil when the unit is not operating.

• When the viscosity of oil is high, it may take some time for the oil to settle. Be careful not to over-fill.

(If oil is filled above the upper line, the temperature wil lrise due to the churning heat of the oil.)

• Use the lower red line on the oil gauge, as a guideline for the normal oil level during operation. (Immediately following

commencement of operation, the oil level may fall below the lower red line, but should not be of particular concern,

since the oil level will recover, as the oil viscosity falls due to the drive operation.)

(5) Oil Discharge

Remove the drain plug shown in Fig. 17 or the lower plug of oil gauge shown in Fig. 18 to discharge oil.

Fig. 17

Fig. 18

Loading...

Loading...