10

FB BRAKE ASSEMBLY – INSPECTION,

ADJUSTMENT & MAINTENANCE

2. Construction and Operating Principles

a. Construction

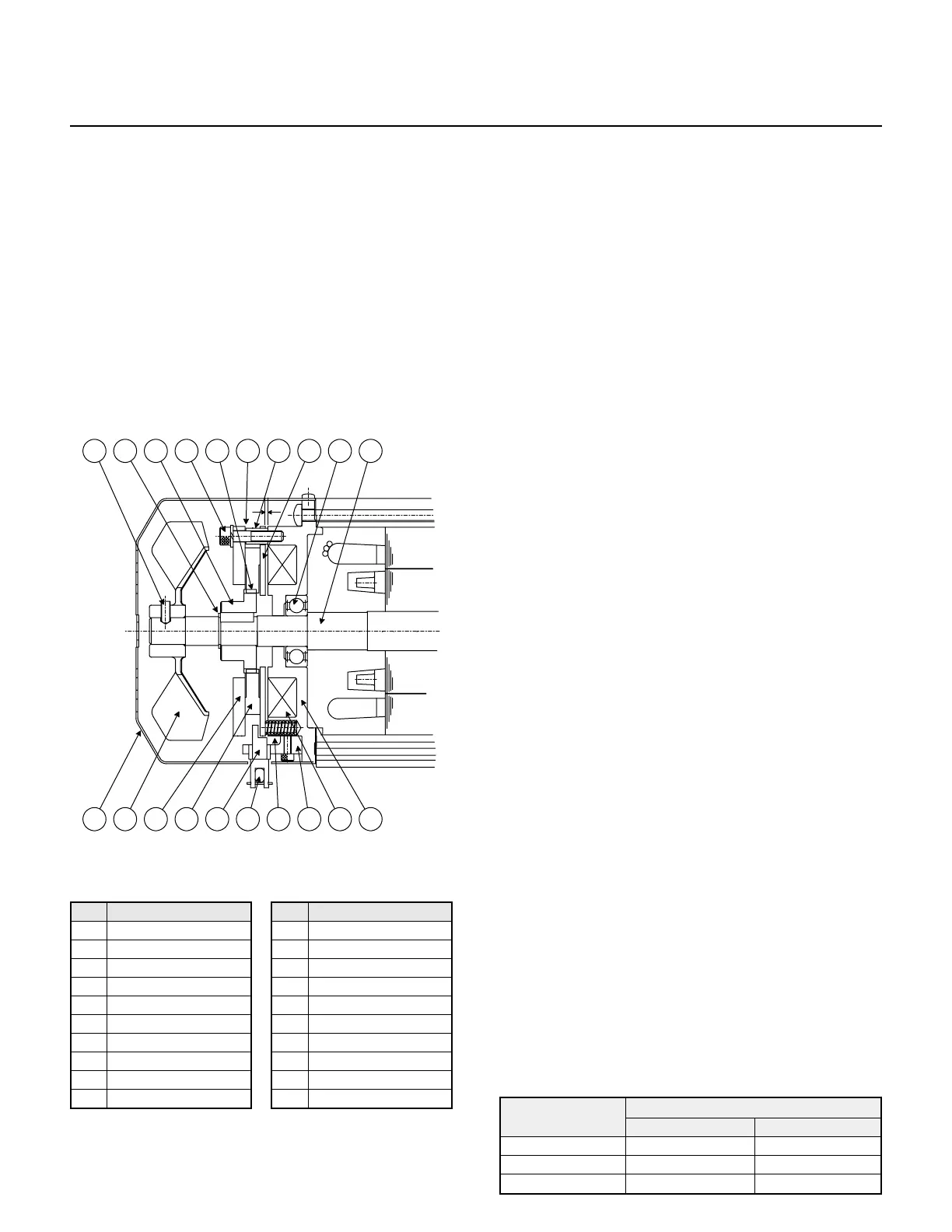

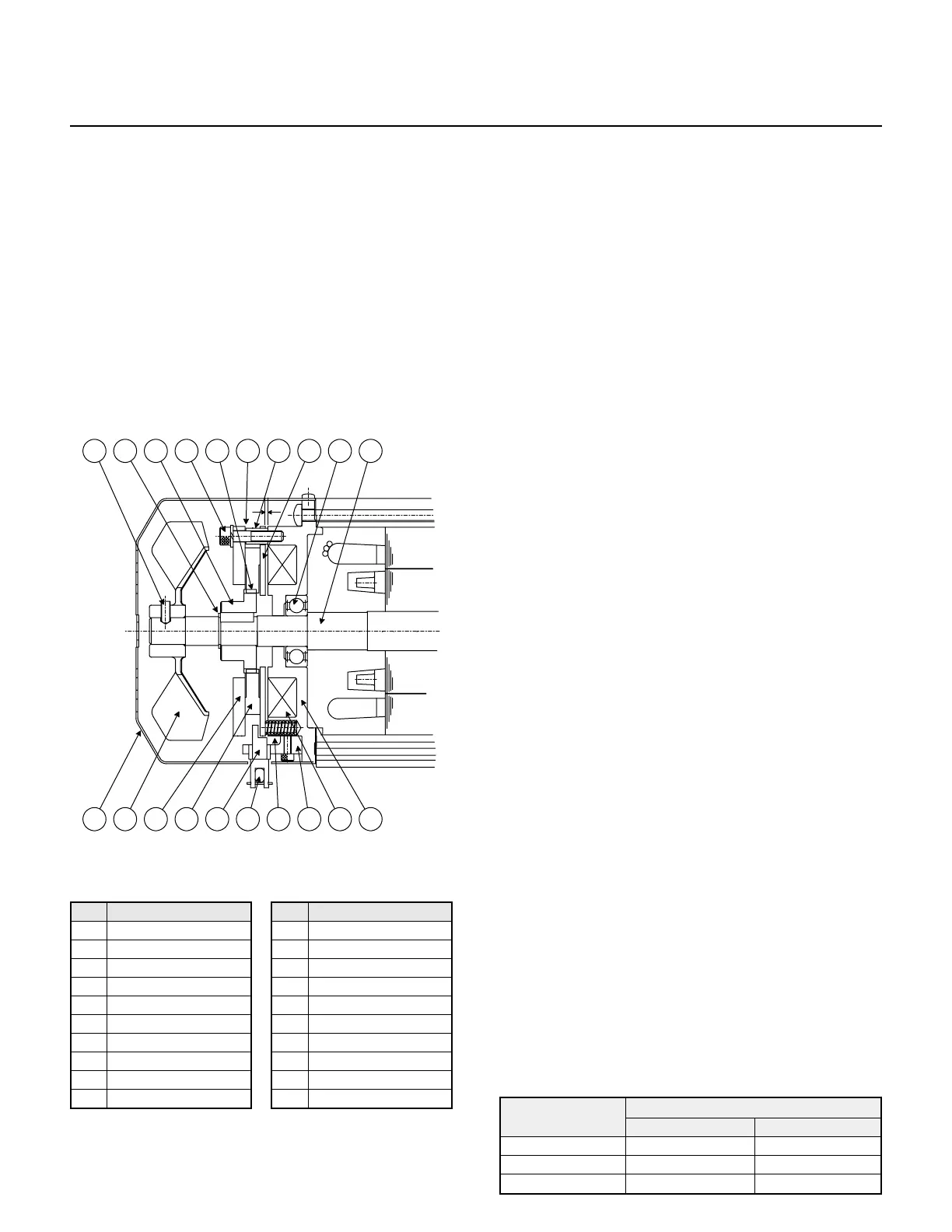

Fig. 17 illustrates the construction of the brake. The

restraining bolt (7) fastens the brake shoe (15), gap

adjusting shim (5) and spacer (4) onto the stationary

core (1). The restraining bolt (7) keeps the armature

plate from rotating, but the plate moves axially by

electromagnetic attraction and the tension of the

pressure spring (17). The brake lining (8) is fitted to

the hub (10), which is secured to the motor shaft with

a key. The solenoid coil (18) is energized via a

rectifier located within the terminal box.

b. Operating Principles

The brake is a (fail-safe type) spring actuated type

brake that releases the brake mechanism when the

solenoid coil is energized and engages when the

solenoid coil is not energized.

When power is applied to the unit, the solenoid coil

and electric motor become energized and the

energized coil attracts the armature plate (16)

against the tension of the pressure spring (17). As a

result, the brake lining (8) disengages and the motor

starts to run.

When the power is disconnected, the solenoid coil

and electric motor are not energized. This causes

the pressure spring (17) to actuate the armature

plate (16), which in turn presses the brake lining (8)

against the brakeshoe (15) and brings the motor to a

quick stop.

3. Inspection

a. At regular intervals, check that:

• the unit is operating normally.

• the brake lining is not excessively worn (or gap

G is normal).

• all the mounting screws are securely tightened.

b. Manual brake release procedure

FB-1B, -2B, -3B brakemotors are equipped with a

one-touch release mechanism. To manually

release the brake with power to the unit turned off,

pull the brake release lever out from its holder and

push it forward toward the reducer. Releasing the

lever will re-engage the brake.

4. Gap Inspection

The brake lining will wear after the unit has been

used for a long period of time. Regularly check that

gap G (Fig. 18) is at an acceptable value. If gap G

becomes too large, the solenoid coil may fail to pull

in the armature plate, and hence cannot release the

brake, resulting in the unit remaining in a

continuously braked condition. Follow these steps to

inspect the brake gap:

a. Remove the cover (12).

b. Insert a gap gage into the space between the

stationary core (1) and armature plate (16).

Measure the gap size at three appropriate

circumferential points.

c. The gap needs to be adjusted if the values are

close to the allowable limit listed in Table 14.

Fig. 18 FB-1B, -2B, -3B Models

No. Part Name

1 Stationary Core*

2 Brake Release Support

3 Shifting Pin

4 Spacer*

5 GAP Adjusting Sleeve*

6 Brake Release Lever

7 Restraining Bolt*

8 Brake Lining*

9 Leaf Spring*

10 Hub*

No. Part Name

11 Retaining Ring

12 Fan Cover

13 Fan Set Pin

14 Fan

15 Brake Shoe*

16 Armature*

17 Pressure Spring*

18 Solenoid Coil*

19 Fan Side Bearing

20 Motor Shaft

*These parts are included in a complete brake kit.

Loading...

Loading...