27 | P a g e

Always ensure a safe working environment as described within this manual when

folding/unfolding wings. Perform movements slow and safely paying special

attention to weight distribution, equality of descent, machine balance & stability,

environmental influences and neighbouring features/obstacles.

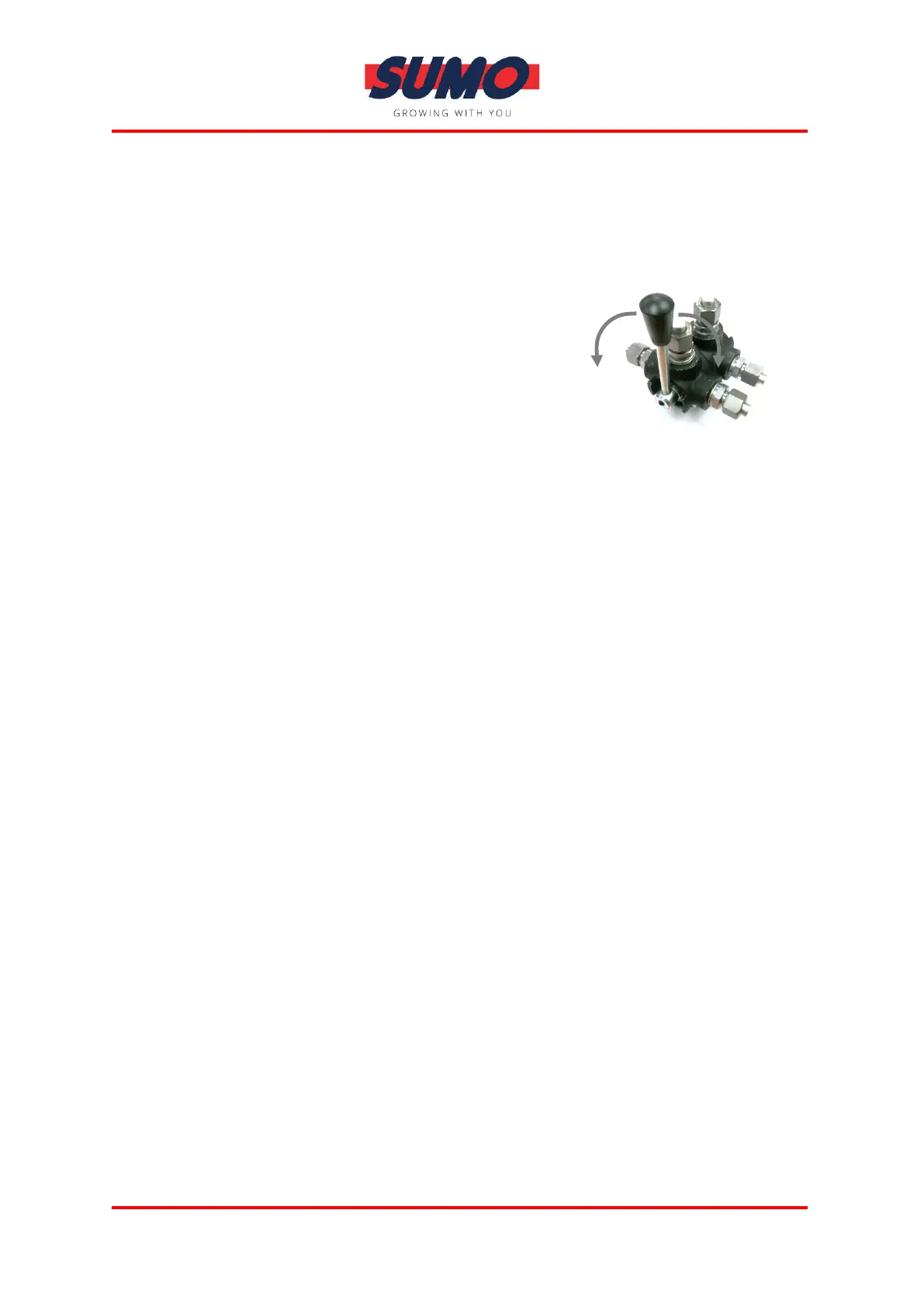

Manual Change-Over Valves (MCOV)

Sumo use MCOV’s to isolate different hydraulic

systems from one another. Depending on the

system required, simply pivot the lever to the

desire direction. Always operate hydraulic

systems slowly to ensure the correct system

has been selected.

Accumulators

Sumo hydraulic systems use high pressure accumulators, which can present a

danger if tampered with or misused. This includes drilling, welding or any other

process that could compromise the safety of the accumulator. It is expressly

forbidden for an operator, or any third party to dismantle or adjust the

accumulator in any way. Doing so will invalidate any existing warranty. If the

accumulator fails it should be changed under the supervision/instruction of Sumo

UK.

5.1.4 Pressurised System

Sumo Drills operate using a pressurised metering system to ensure controlled

and consistent seeding. It is therefore vital air leaks are kept to an absolute

minimum to ensure that metering remains accurate. Failure to isolate leaks may

cause substantial metering errors. During operation it is imperative hopper lids

should remain closed and sealed. It is good practice before drilling commences

to manually check that there is no air leaking from the lid seals. See ‘Hopper Lids’

section regarding the adjustments to hinge and catch to improve seal quality as

the machine ages. It is important to check all seals on the pressurised system

on a daily basis i.e. hopper lids, nylon sleeve, Orga inserts and replace where

necessary to ensure that the metering is accurate throughout the life of the

machine.

5.1.5 Hopper Lid

Hopper lids are adjustable to ensure you can create an airtight seal throughout

the life of the machine. Seals should be checked to ensure that they are creating

an airtight seal and should be replaced when they cease to function. When

drilling it is vital that the hopper lids are closed and secured, this will prevent air

leaks from the hopper that can lead to metering problems. The drill operates

using a pressured system to ensure a positive, consistent seeding rate.

Loading...

Loading...