29 | P a g e

• Information totals

Please see your isocan Artemis manual for further guidance.

5.2.3 Hydraulic Coulter Positioning

The hydraulic coulters run using a constant oil supply from the tractor. The

pressure in the system is regulated using a pressure relief valve located at the front

of the drill near the storage locker. The pressure gauge fitted to the valve displays

the working pressure. About 10 L/min (or approx. 20%) of oil will be required to

allow the coulters to respond to changing ground conditions. If coulters don’t

respond fast enough increase the oil flow, but care must be taken not to over-

supply to a point where the fans oil supply is compromised.

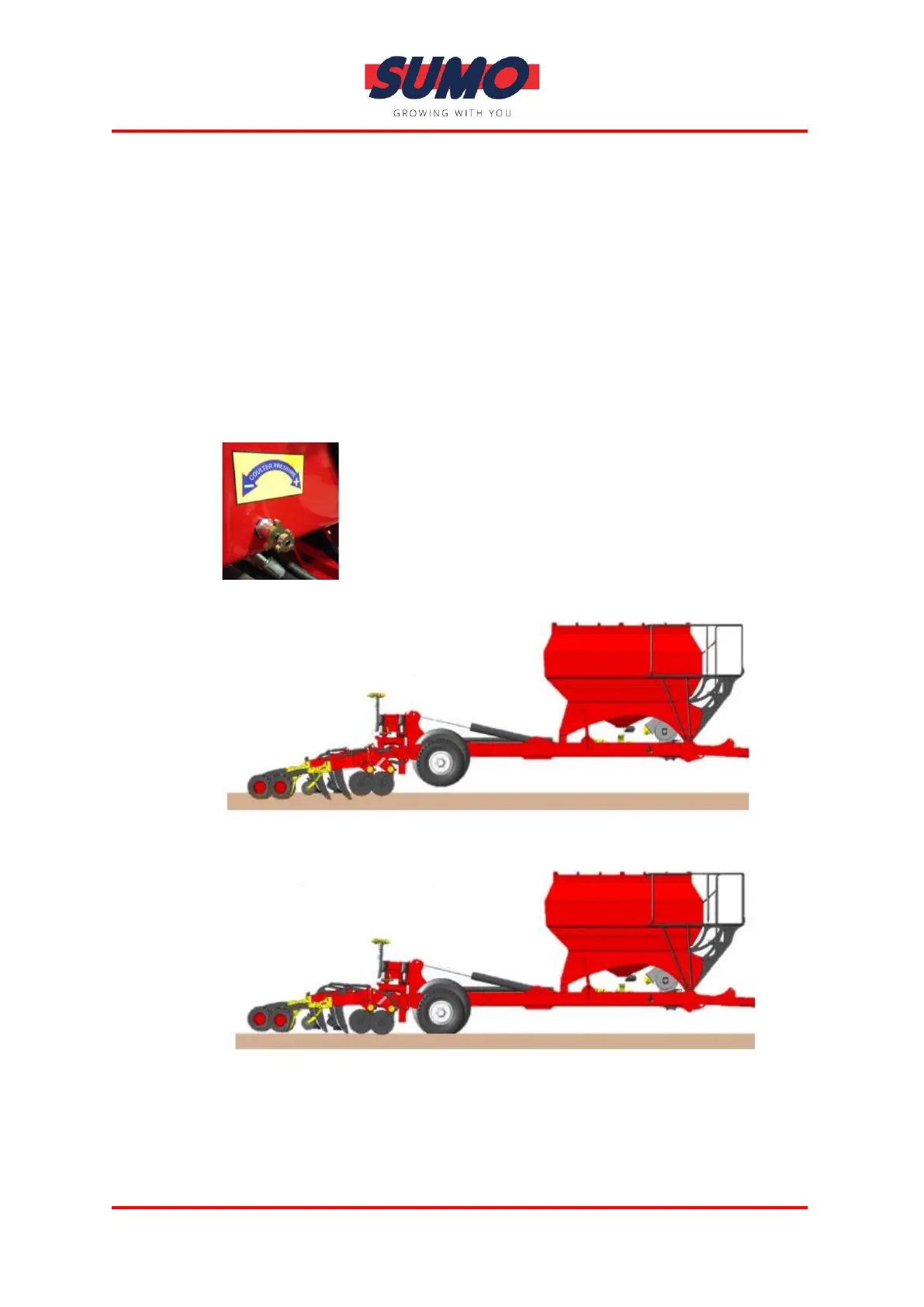

The default working pressure is 30bar for DTS machines & 50bar

for DD machines. This pressure will need to be adjusted

according to local conditions. For example, it will need to be

increased slightly (+/-5bar) as the leg is set to work deeper. Soil

types, stone concentrations and desired firming will all influence

the pressure setting. The pressure should not be set so high that

the transport wheels are lifted off the ground.

Chassis wheels lifted off the ground.

Wheels on the ground but not penetrating.

Loading...

Loading...