36 | P a g e

Under the toolbox at the front of all trailed machines is a flow control valve tap

which controls the flow to the main lift rams and also the seeding shut-off ram.

The shut-off ram has a magnet attached to one end that starts and stops seed

dispensing based on its proximity to the parent sensor. Correct balancing is

essential to maintaining a responsive system.

Less flow means the shut off responds quicker but lift will be fractionally slower.

More open, will result in a quicker lift but will mean the shut off ram becomes lazy

and could result in over-seeding at the end of each run and delays at the start of

each run.

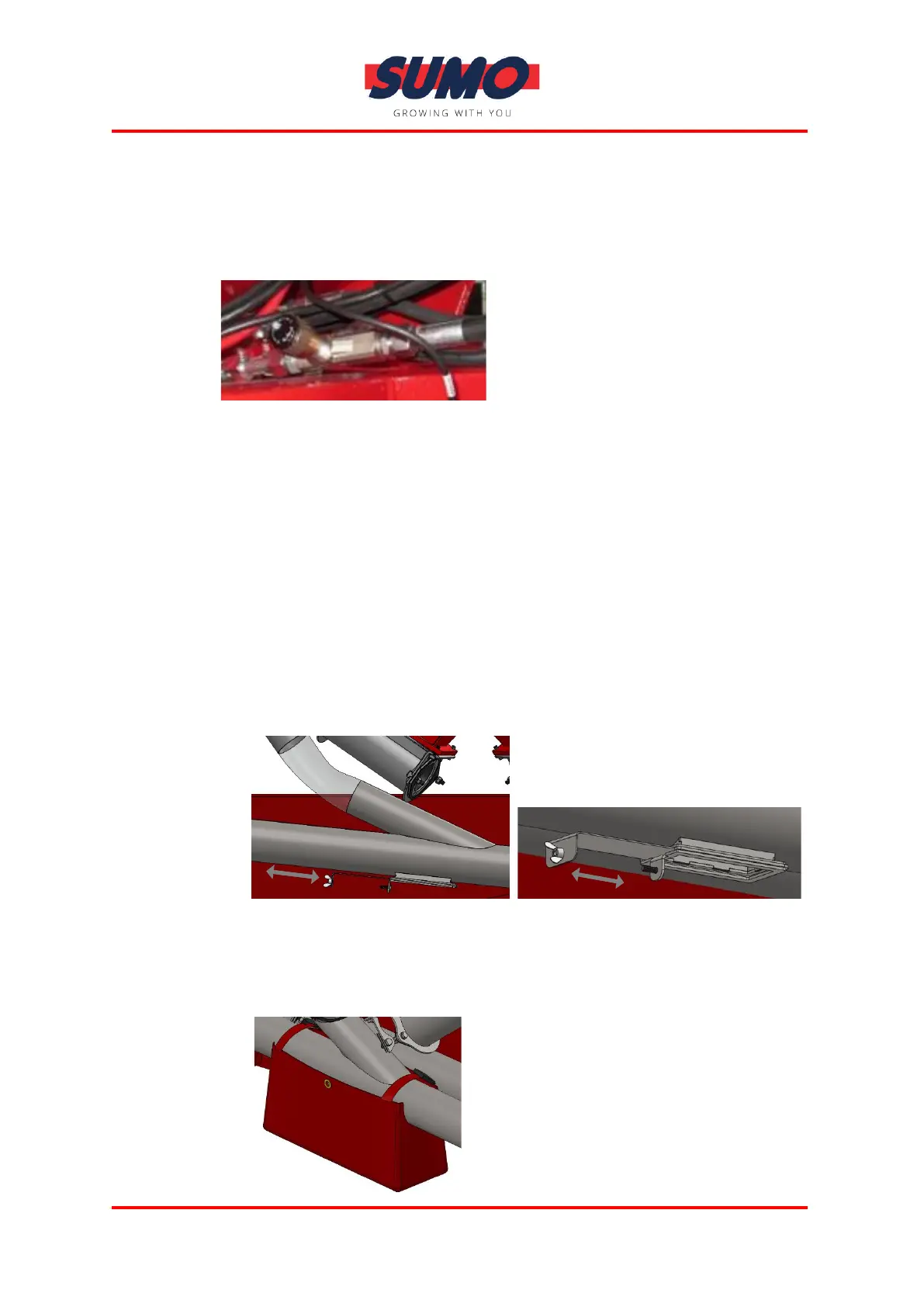

5.2.8 Calibration System

Is a simple valve to allow seed to drop through an outlet in the Seed/Fert transfer

pipe to calibrate the drill for a required seed rate. When the flange is pointing

down, the valve is shut. When the flange is pointing horizontal, the valve is open

(calibration position). Ensure this is closed before commencing seeding.

1. Open slide portal to allow seed to flow out of the Air Transfer Pipe directly

below the Orga metering outlet.

2. Switch the scales ON and check units (kg). Zero the scales with the weight of

the calibration bag.

3. Positions the calibration bag to the Air Transfer Pipe using the straps.

Loading...

Loading...