Document Number: MKT-70-1096 Revision 1 Page 17

SYSMEX XE-5000

TM

XE Pneumatic Unit:

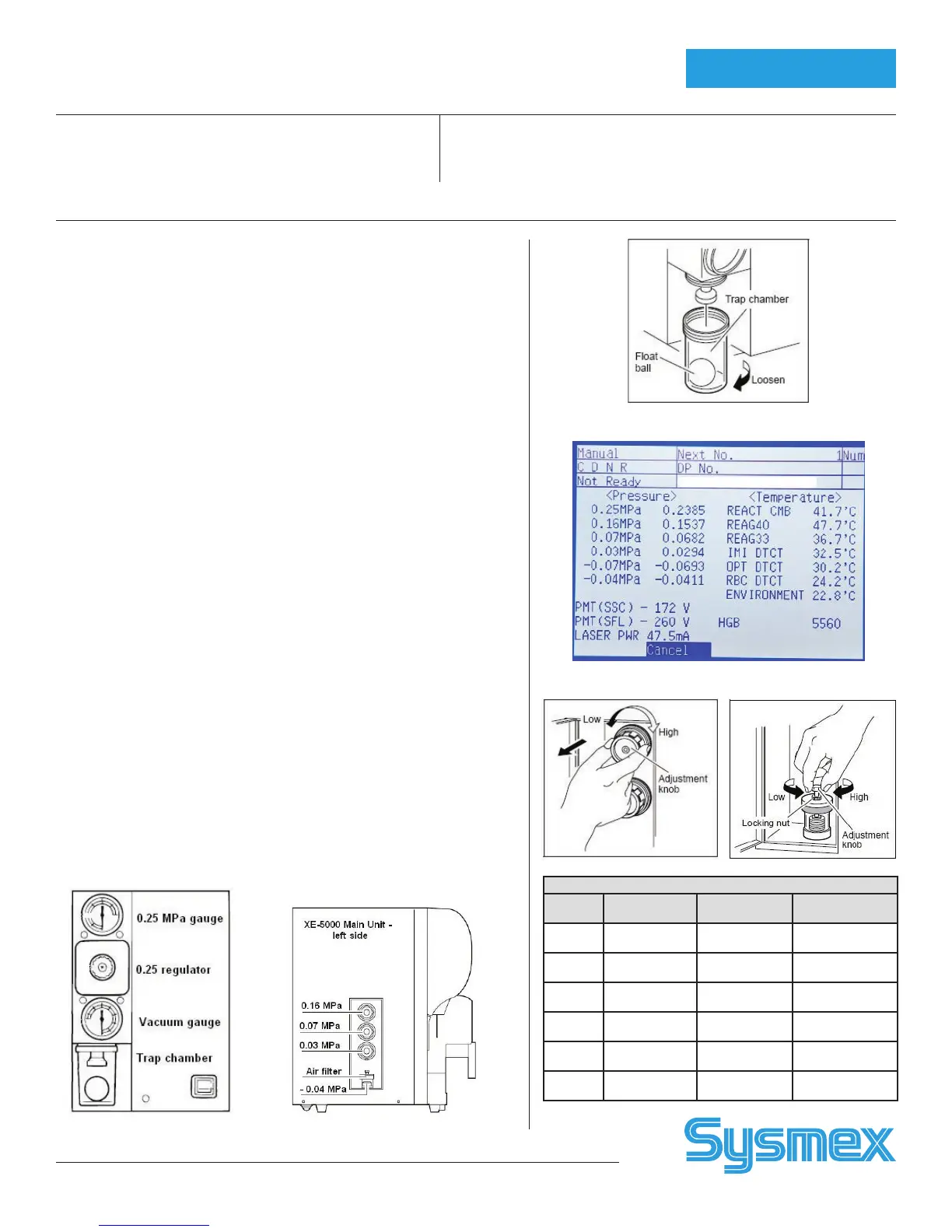

Inspect Trap Chamber for Fluid

• Visually inspect Trap Chamber for fluid.

• If fluid is present, turn Pneumatic Unit off. Remove Trap Chamber by

turning clockwise. Discard fluid. Dry chamber and re-assemble trap on

Pneumatic Unit. Do not over-tighten.

• Turn Pneumatic Unit On. Verify vacuum gauge is accurate.

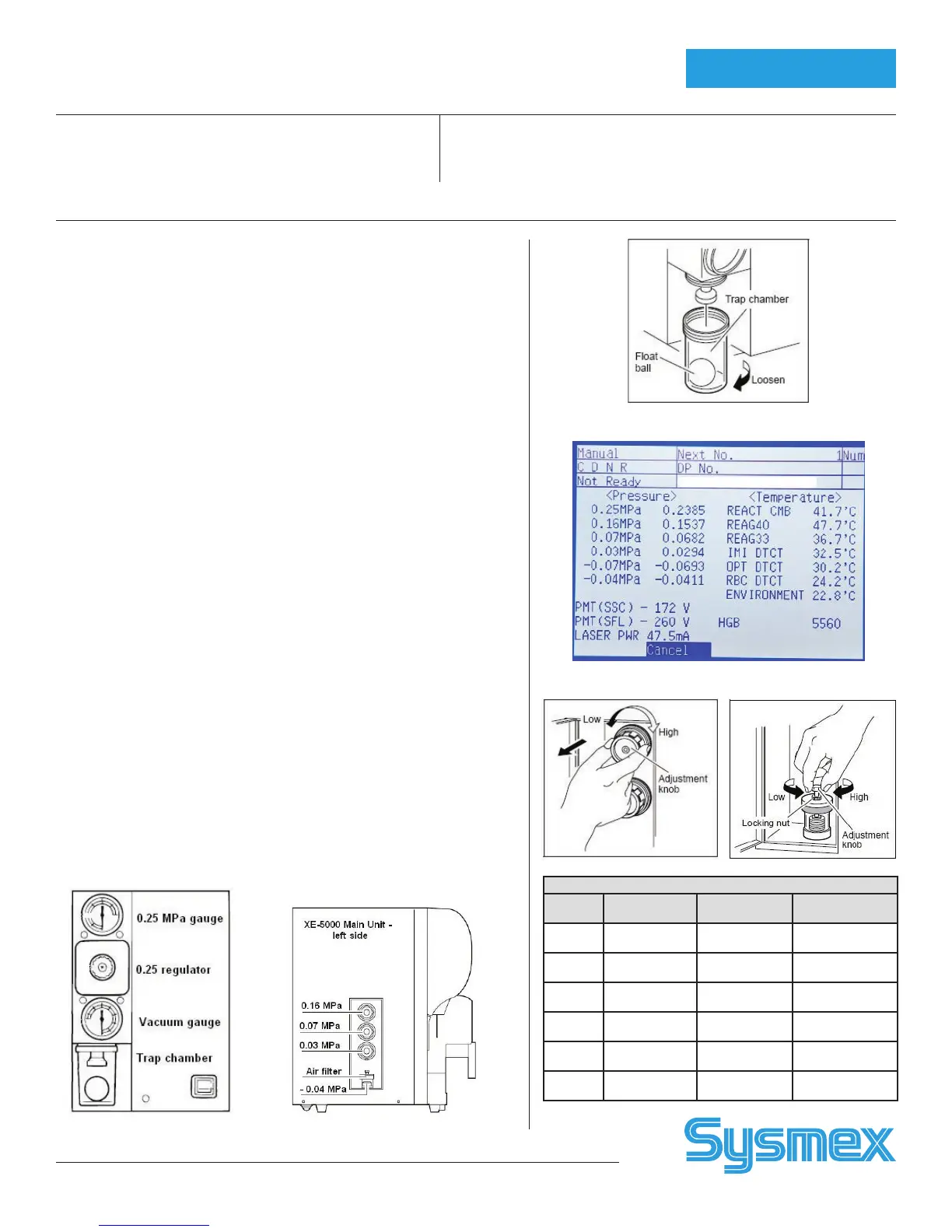

XE Pressure and Vacuum Checks

• XE Main unit sensors monitor ranges for pressure and vacuum. If moni-

tored ranges are exceeded (see Table), error messages are displayed.

Press [HELP] and [OK] to display Sensor 1 screen. Then adjust to cor-

rect the error.

• Check pressure and vacuum on Pneumatic Unit before checking the

Main Unit.

• Adjustment procedures listed below. Set using the adjust range (see

Table).

To Adjust XE Pneumatic Unit Pressure

• View XE Sensor 1 screen

• Loosen fixing screw using screwdriver

• Adjust 0.25 pressure using knob

To Adjust XE Main Unit Pressure

• View Sensor 1 screen

• Pull knob to unlock

• Adjust regulator to range

• Push knob in to lock in place

To Adjust XE Main Unit Vacuum

• View Sensor 1 screen

• Loosen lock nut on bellows unit

• Adjust using adjustment knob

• Retighten lock nut

Vacuum Trap Chamber

Sensor 1 Screen

Maintenance

Pressure and Vacuum (In Order of Sensor 1 Screen)

XE-5000

Adjust Range

MPa

Monitored

Static Range

Adjust

Location

PU

Pressure

0.24 to 0.26 2100 to 2900

PU

Regulator

0.16

Pressure

0.159 to 0.161 1500 to 1700

XE Main

Unit

0.07

Pressure

0.069 to 0.071 620 to 780

XE Main

Unit

0.03

Pressure

0.029 to 0.031 270 to 330

XE Main

Unit

PU

Vacuum

must be ≥- 0.05 400 to 700

No PU

Adjustment

- 0.04

Vacuum

- 0.039 to

- 0.041

285 to 315

XE Main

Unit

Loading...

Loading...