interference with the sampling point, it may be necessary to

increase this time delay. Delay values of up to 240 seconds before

signalling a fault are available when setting up the FAAST LT

detector. This is to allow time for the air pressures to stabilise after

the temporary event.

When a ow fault occurs, the ow fault LED blinks during the

programmable ow fault delay (default: 60s). At the end of the

delay, the LED switches ON and the general fault is triggered. If

the general fault also has a delay programmed, this will be added

to the ow fault delay before the general fault LED becomes xed

ON and the fault relay is set.

Events log

The detector records operations and trouble states in a log with

time and date stamps. The event log is a useful tool to help with for

troubleshooting an installation. The user can download data logs

via a USB port when connected to a PC running Pipe IQ.

The maximum number of events in the log is 2244. When the

recording area is full, the FAAST LT unit continues to store

abnormal events by over-writing the oldest records.

For each recorded event, the log contains the following information:

event descriptor, date and time, the airow temperature, the airow

rate, the power supply voltages and the state of the laser sensors.

Events include the detector state (Initialising, normal, service

mode etc.), alarms, faults, alerts and relay activation/deactivation.

Trend logging (recording the device status at regular intervals) is

disabled in the FAAST LT as a factory default. Enabling the trend

log will ll the event log quicker. For example, setting the trend

interval to 10 minutes will ll the complete log in just over 2 weeks.

RELAY OUTPUTS

Single pole changeover volt free unsupervised contacts are

provided for Fault, Auxiliary Fault, Alarm and Pre-Alarm (on stand-

alone version only). On two-channel devices, there are two sets of

alarm and pre-alarm relays. In Table 4 below, SA relates to Stand-

Alone and LB relates to a Loop Based FAAST LT device.

WARNING: Because the relays use magnetic latching, the contact

output status should be checked prior to use powering any circuit,

in case it has changed due to mechanical shock during shipment

or installation handling.

Resetting a detector from alarm or fault

When an alarm or fault is latched, the FAAST LT detector should

be reset from this condition using one of the following methods.

(Note: By default Alarms are latched, Faults are not.)

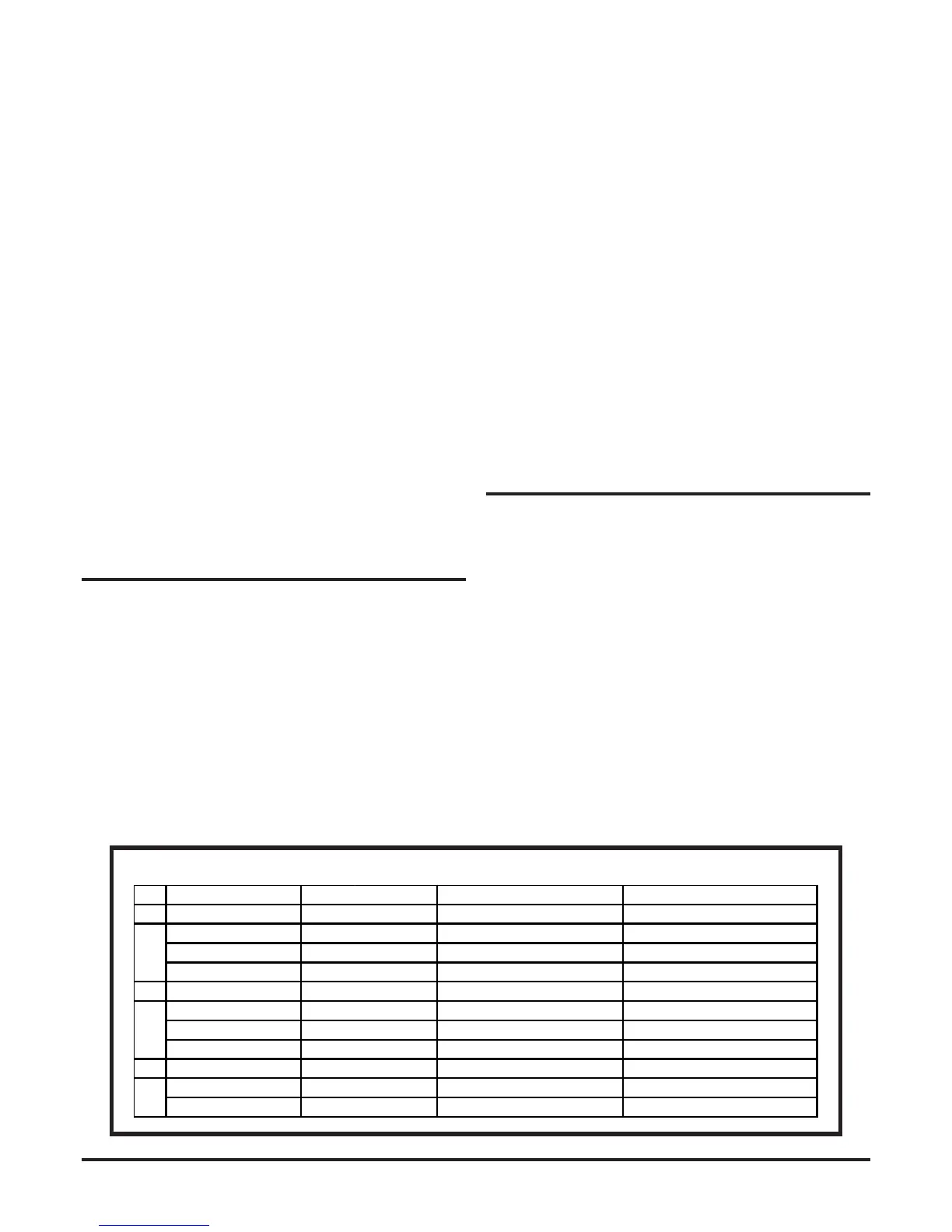

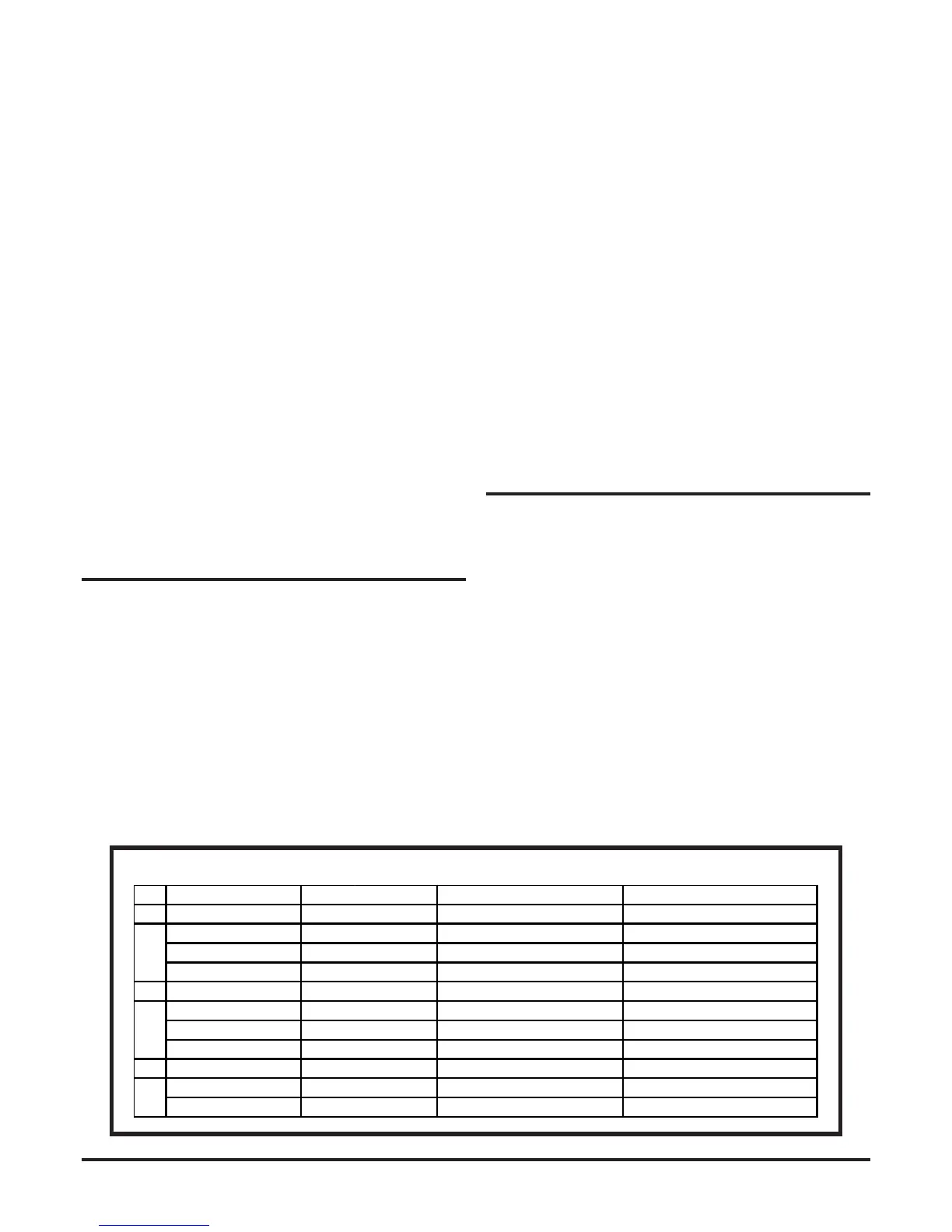

Table 4: Relays

Type Relay Whenset Notes

Alarm Default=Latched Sensorreachesalarmlevel Defaultdelayis0

Pre‐Alarm Notlatched Sensorreachesalarmlevel Defaultdelayis0

Sounder Notlatched AlarmorPre‐Alarm

Alar m(sensormode) Default=Latched PanelsetssensorremLEDON Defaultmode;defaultdelayis0

Alar m(modulemode) Default=Latched PanelsetsmoduleoutputON

Sounder Notlatched Alarm

Fault Default=Notlatched Oneormorefaults FactorydefaultasCH1faults

Auxiliary Default=Notlatched ConfigurablewithPipeIQ FactorydefaultasCH2faults

Both

Latching

SA

LB

● Press the front panel Reset button when in Maintenance mode;

(requires pass-code access). Return to normal operation by

pressing R+T+D simultaneously or waiting 5 minutes.

● Use the External Input; set to RESET as factory default.

Connect Input terminals 21 and 22 together for a short period.

● It is possible to perform an alarm reset from a PC using the reset

control available in the PipeIQ software; (requires activating the

USB connection, then go to: Monitoring tab > Actions tab >

Click Reset at bottom right).

● For loop based units only, Advanced Protocol panels may send

a Reset signal over the loop if this feature is enabled (check

with panel manufacturer) and the FAAST LT device is operating

in module alarm mode.

When a RESET is performed, all relays are reset. The device

then enters Normal mode operation; it does not re-initialise. If any

fault or alarm states remain, the device will re-activate that state

automatically.

General reset of a detector

The FAAST LT device will be reset and re-initialised by removing

the external power to the device and reapplying it. In general, this

is not an acceptable method for clearing latched alarms or faults

during normal operation because it will re-initialise the device ow

settings.

PASSWORD RECOVERY

There is a procedure that can be used to recover a lost password

from a FAAST LT device. It should be used when a unit has been

installed and the password has been changed but is subsequently

forgotten or misplaced. The default (factory set) password in a new

device is 3111.

To reset a FAAST LT password it is necessary to run some special

software to obtain a recovery key. For instructions and help with

this recovery procedure, contact System Sensor Europe Technical

Services (sse.technical@systemsensor.com) and provide the

following information:

● Product Model number: (on device label)

● Device Serial Number: (on device label)

● Date code: (4 digit number followed by the letter T, to be found

at the bottom right-hand side of the product label on the back

of the front door)

● Name of Requester and Requester Organisation:

Note: This service is only available to Honeywell or accredited

System Sensor OEM customers.

Loading...

Loading...