127

MAINTENANCE

Every 50 Hours

Lubricating the Slew Bearing

WARNING

Do not slew while lubricating. Doing so

is dangerous, as you may get caught in

the machine.

1. Stop the engine with the machine in the

posture shown on the diagram above.

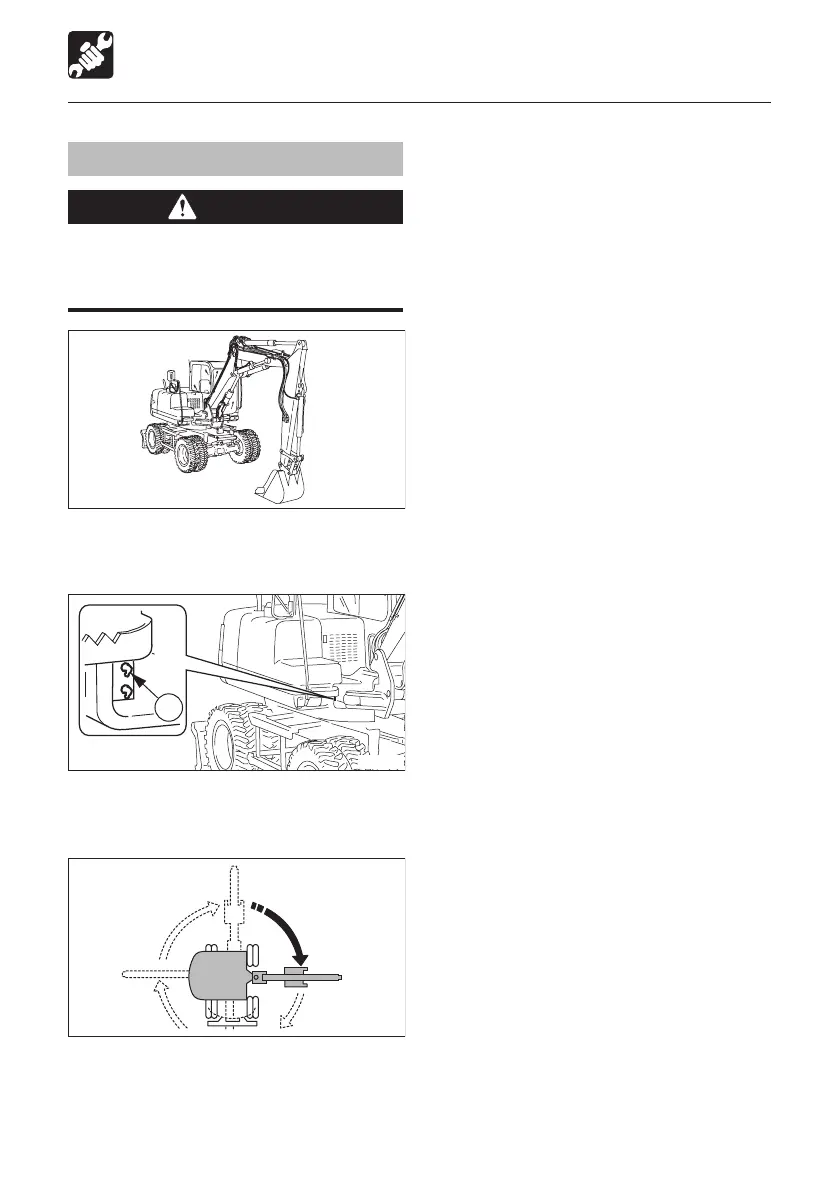

2. Use the grease gun to supply grease to the

grease nipple (1).

3. Start the engine, lift the bucket and slew

clockwise 90°.

4. Ground the bucket and stop the engine.

5. Repeat steps 2 to 4 above three times.

6. Wipe off the grease expelled from the slew

bearing and grease nipple.

Loading...

Loading...