GENERAL

I-10TB53FR

CAUTIONS DURING REMOVAL AND

INSTALLATION OF THE HYDRAULIC UNITS

1. Make sure that the hydraulic oil’s temperature

has dropped.

2. To prevent a loss of flow of the hydraulic oil, the

residual pressure in the piping and the internal

pressure in the hydraulic oil tank should be bled

out.

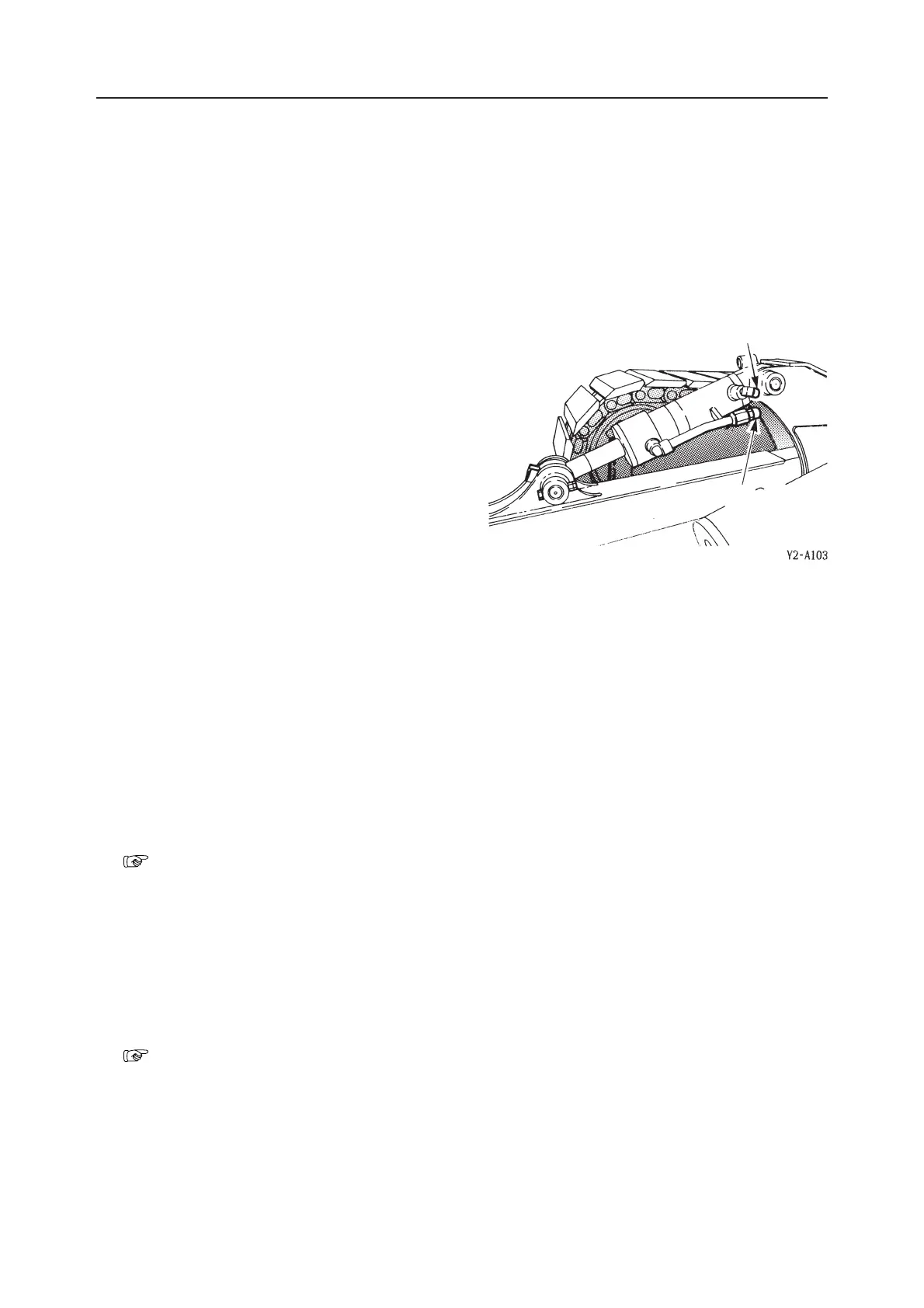

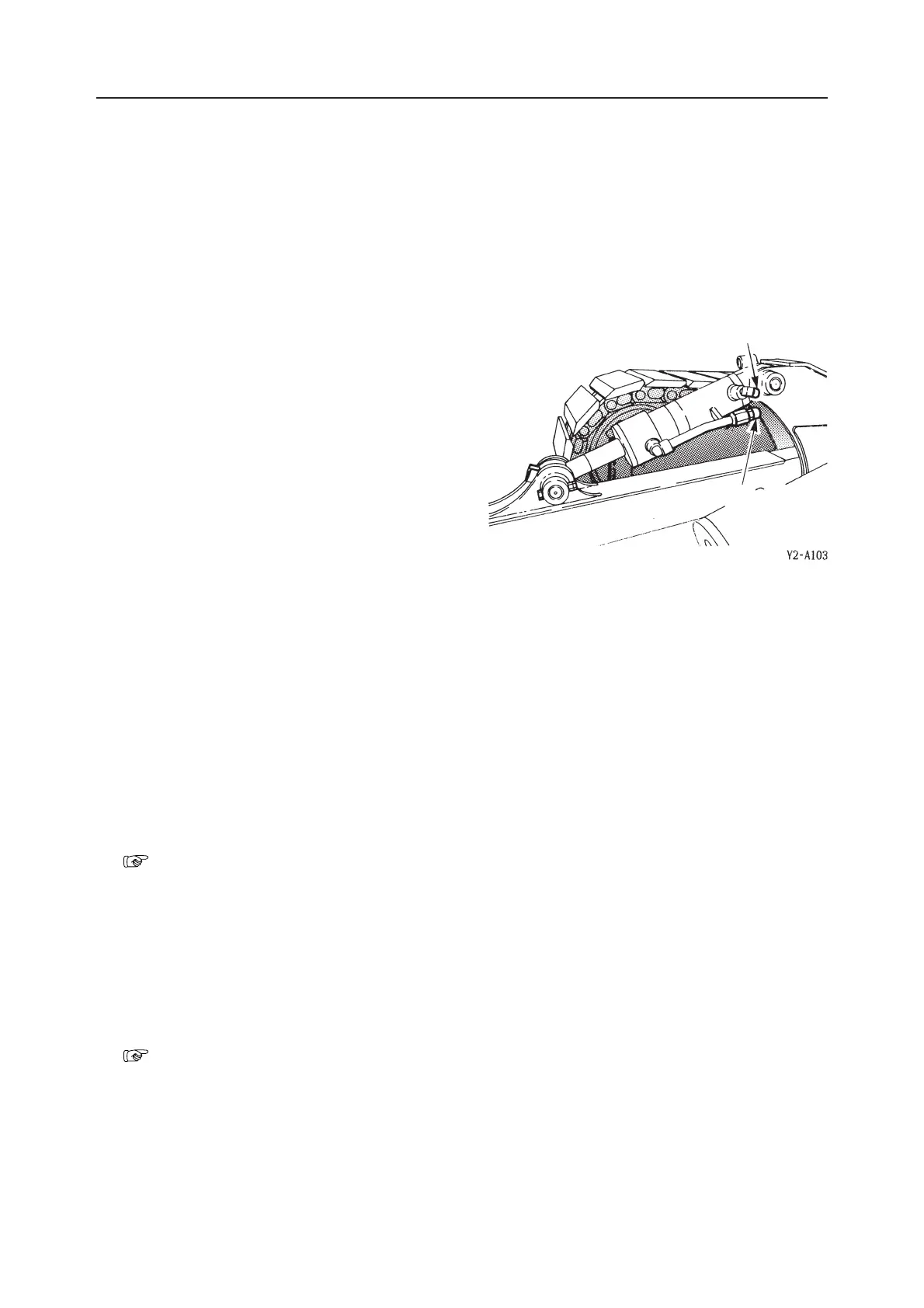

3. Be sure to install caps or plugs on all openings in

the hydraulic unit to prevent dirt from getting into

the unit through the openings.

4. It is easy to mistake hydraulic oil adhering to the

hydraulic unit for an oil leak, so wipe the unit off

thoroughly.

5. Be sure that no damage is done to the plating on

the rod in the hydraulic cylinder.

6. As a rule, removal and installation of the hydrau-

lic cylinder should be done with the rod fully

retracted.

7. Be sure to bleed the air after replacing the hydrau-

lic oil or removing any of the hydraulic devices.

“III. Machine Configuration, Hydraulic Sys-

tem”

8. After installation of the hydraulic unit, be sure to

pressurize the hydraulic oil tank. If this operation

is forgotten, it could cause cavitation of the hy-

draulic pump. Also, it could have a drastic effect

on the life of the hydraulic pump.

“III. Machine Configuration, Hydraulic Sys-

tem”

PLUG

PLUG

Loading...

Loading...