15

Models 340/341/342

Systems and Controls

Torque Control

Function/Operation

The thickness (and indirectly the temperature) of the

slush is controlled by a sensing device called the

Torque Switch. The refrigeration system is brought on

and off by a microswitch.

Inside the beater is a torque rotor to sense the

thickness of the product in the freezing cylinder. The

torque rotor should be inserted in the beater drive shaft

at the rear, and in the center of the door at the front.

When the beater turns, the moving product freezes

and exerts a clockwise pressure against the rotor as

the product thickens. This pressure is transmitted to a

torque arm, operating arm and spring.

When enough tension is produced, the microswitch is

tripped, breaking current to the holding coil of the

compressor; cycling the system off. As soon as the

compressor cycles off, the timer starts its 10 minute

timing period. When 10 minutes have elapsed, power

is sent through the timer to the solenoid. The solenoid

pulls the operating arm to the left, tripping the

microswitch. The microswitch sends power to the

holding coil of the compressor contactor; and the

system starts. When the product reaches serving

viscosity, the torque arm moves to the right, tripping

the microswitch, and the compressor stops. At this

time, the timer resets back to “0”.

When the draw handle is raised, the anticipator arm

assembly moves the torque arm to the left, tripping the

microswitch; starting the compressor.

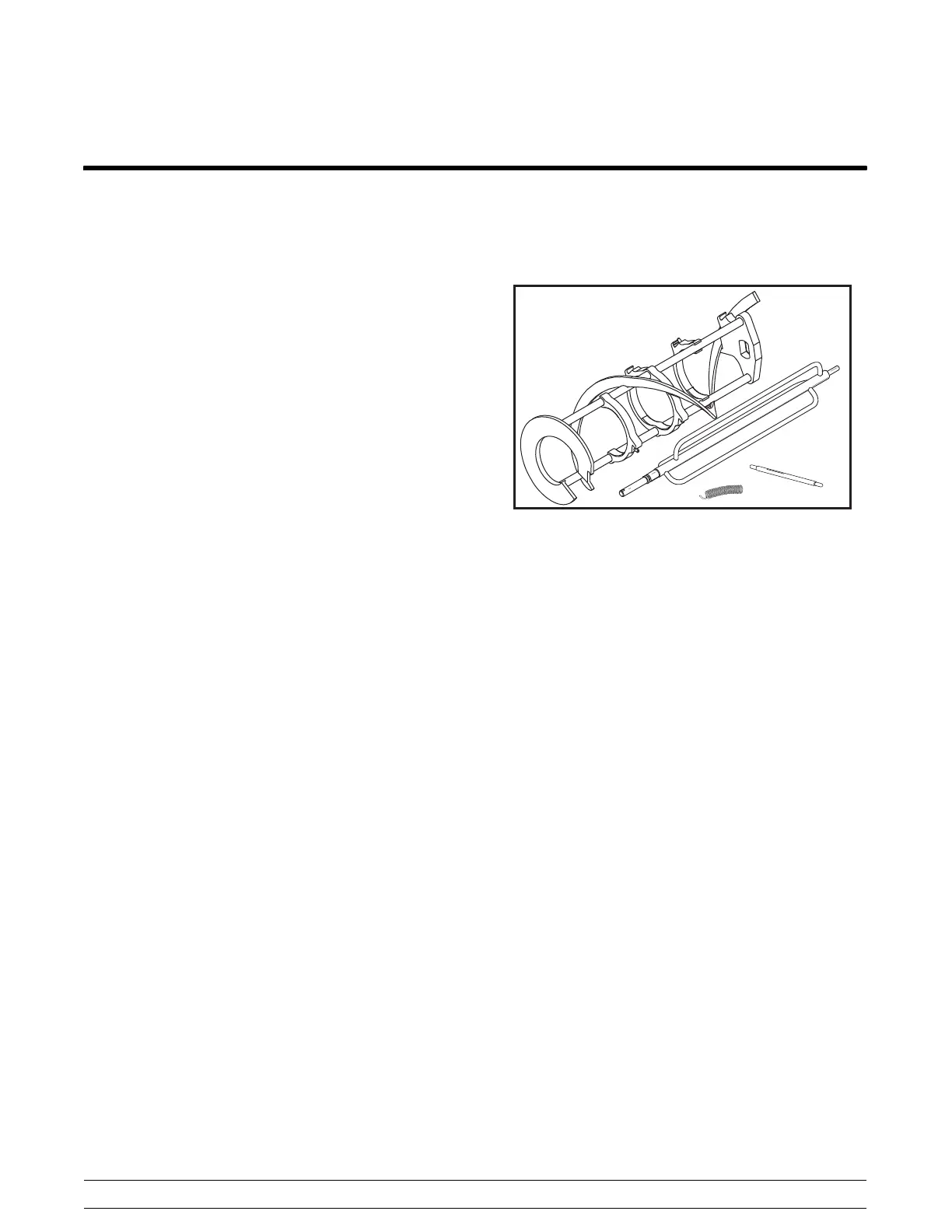

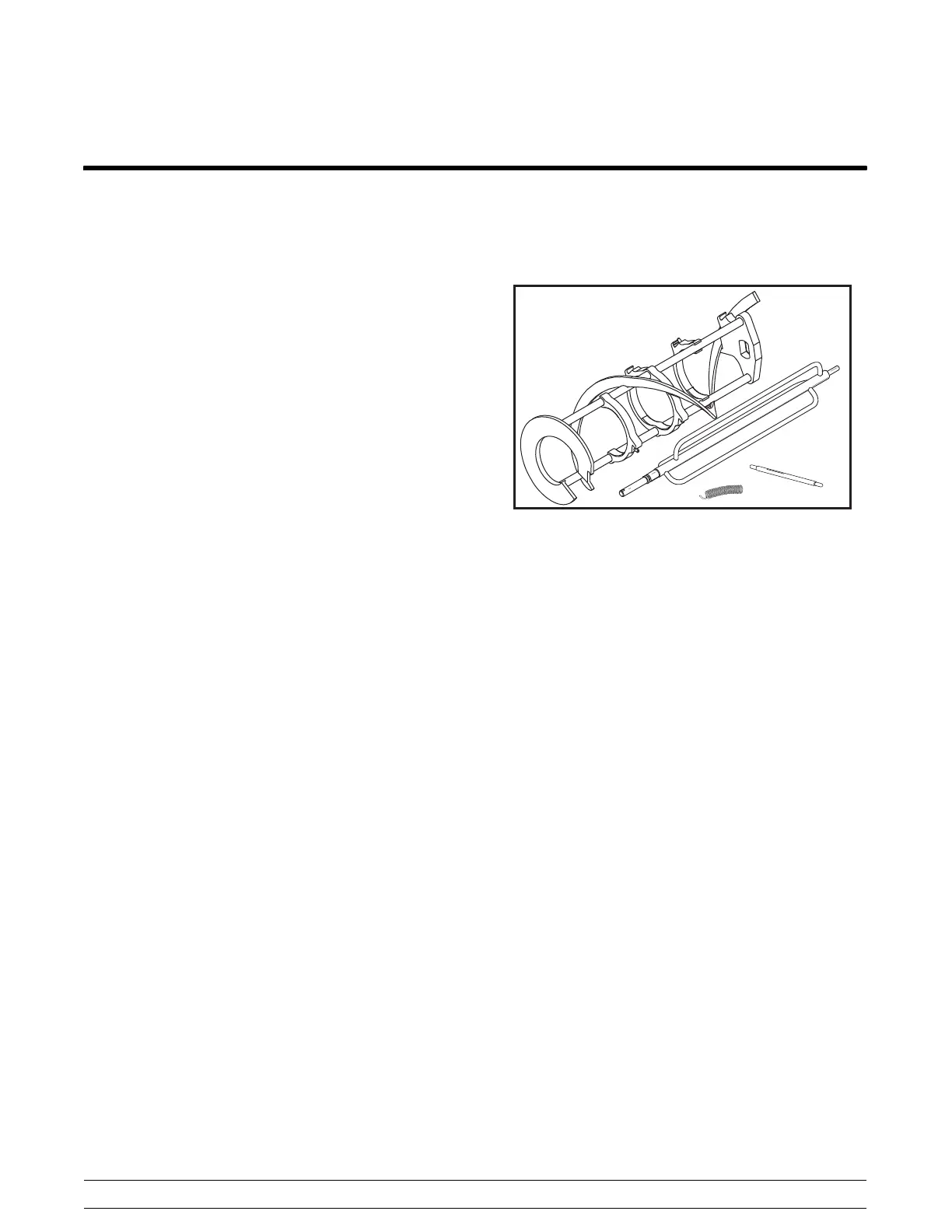

11178

Figure 1

Adjusting t he Torque Switch

To achieve a thicker slush consistency, turn the

adjustment knob clockwise. This will increase the

spring tension, making it more difficult for the torque

arm to overcome the spring tension to trip the

microswitch.

To achieve a thinner slush consistency, turn the

adjustment knob counter--clockwise, to decrease

the spring tension.

Loading...

Loading...