6-4

OPERATING PROCEDURES

Models C709 & C717

Operating Procedures

6

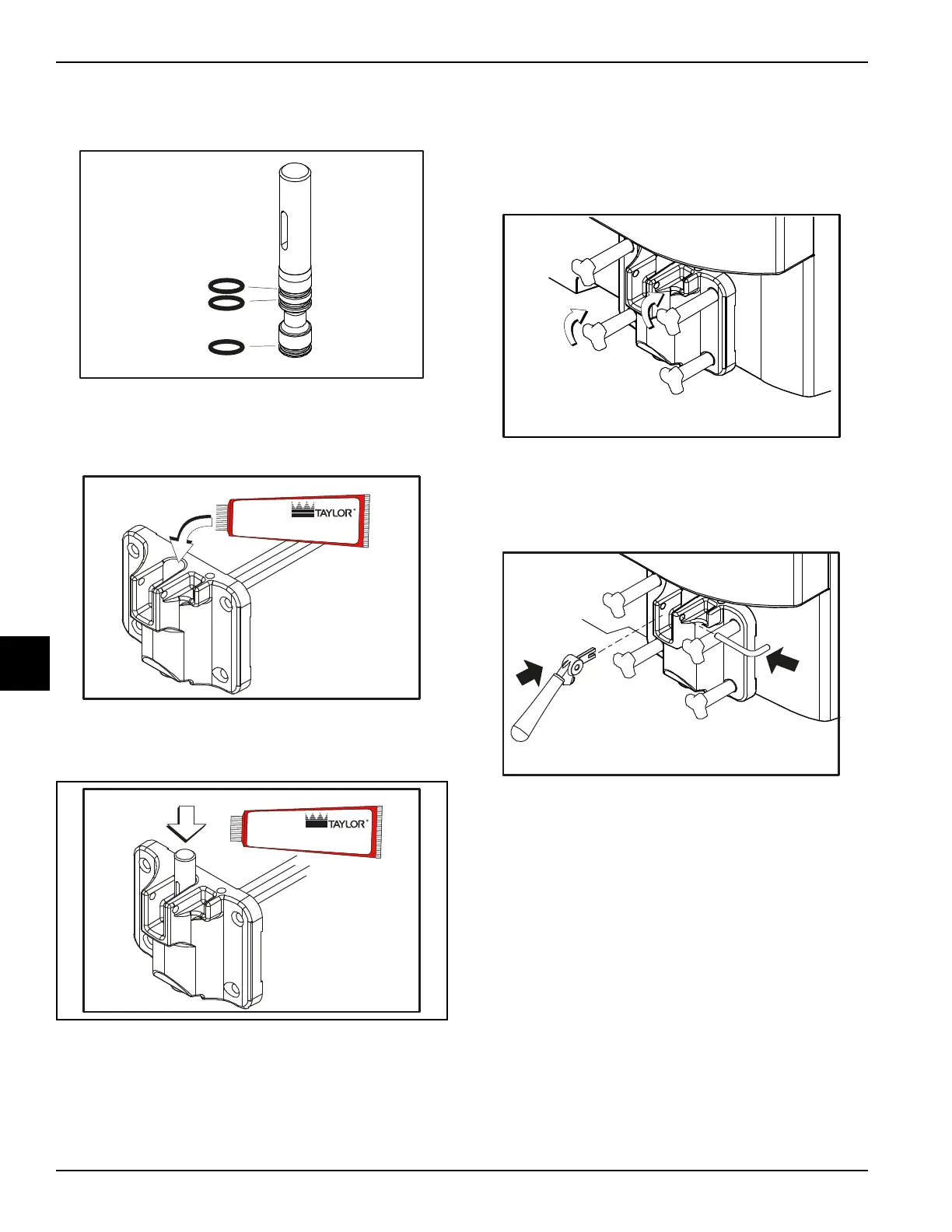

3. Slide the three O-rings into the grooves on the draw

valve and lubricate.

Figure 6-13

4. Lightly lubricate the inside of the top of the freezer

door valve cavity.

Figure 6-14

5. Insert the draw valve from the top, with the draw

handle slot facing forward.

Figure 6-15

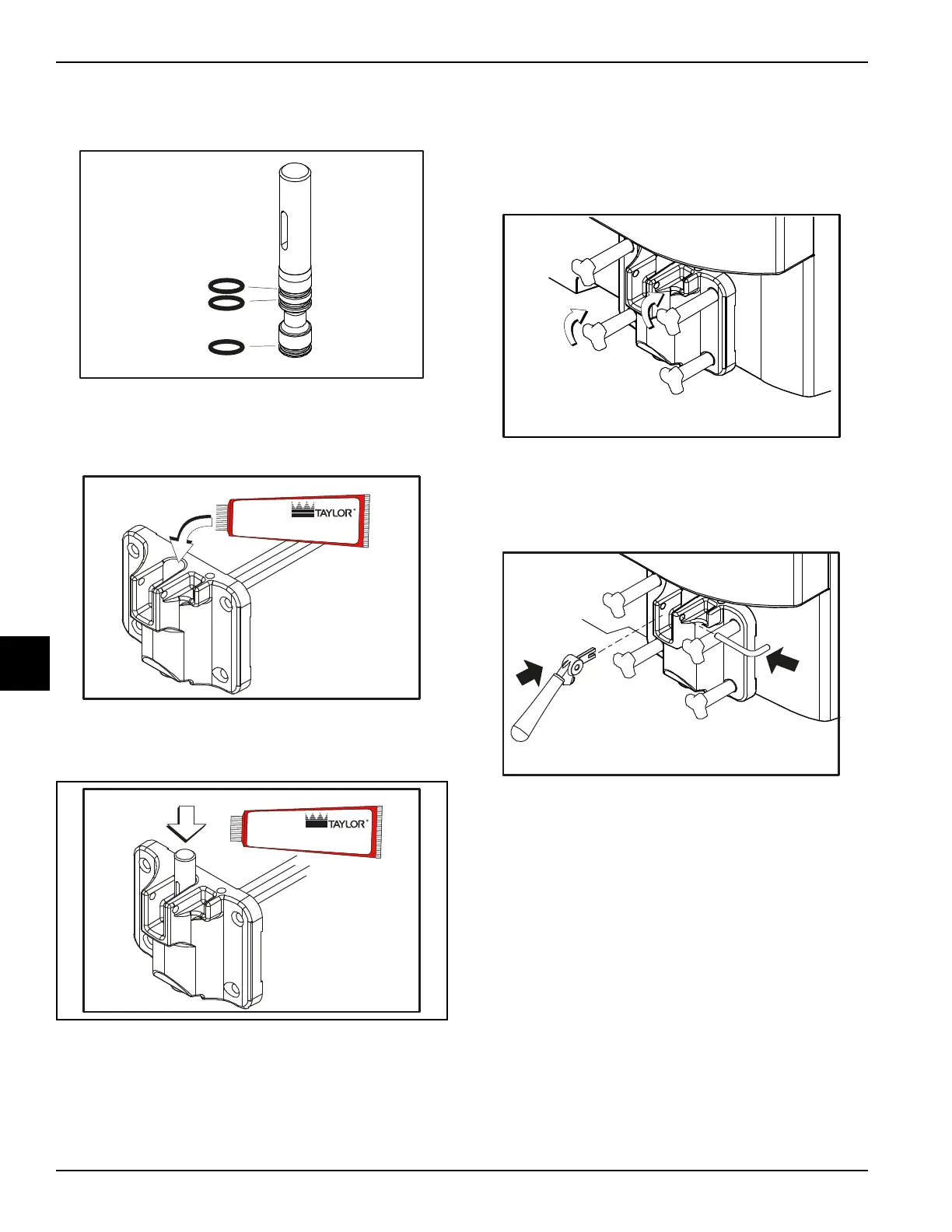

6. Insert the baffle rod through the beater in the freezing

cylinder. With the door seated on the freezer studs,

install the handscrews with the longer ones on top.

Tighten equally in a crisscross pattern to make sure

the door is secured.

Figure 6-16

7. Position the draw handle with the adjustment screw

facing down. Slide the fork of the draw handle into

the slot of the draw valve. Secure with the pivot pin.

Figure 6-17

Note: The C709 features an adjustable draw handle

to provide portion control, giving a better, consistent

quality to your product and controlling costs.

The draw handle should be adjusted to provide a flow

rate of 5 oz. to 7-1/2 oz. (142 g to 213 g) of product

by weight per 10 seconds. To increase the flow rate,

turn the adjustment screw clockwise. Turn the

adjustment screw counterclockwise to decrease

the flow rate.

10390

Apply the appropriate

Taylor approved food safe lubricant.

HP

10500

Apply the appropriate

Taylor approved food safe lubricant.

HP

Loading...

Loading...