14

Most suspension seat posts can be

adjusted to the rider’s weight. How-

ever, in most cases this requires the

seat post to rst be extracted from the

frame. Please talk to your specialist retailer

before carrying this out.

Suspension frames and their suspension-

related parts

In this case, the frame’s rear fork is exible and

has suspension and damping from a shock ab-

sorber.

Some shock absorbers use a steel spring to ab-

sorb undulations, while others do this with an

air chamber. The damping, which regulates the

speed of compression and stretching, can be ad-

justed in high quality shock absorbers.

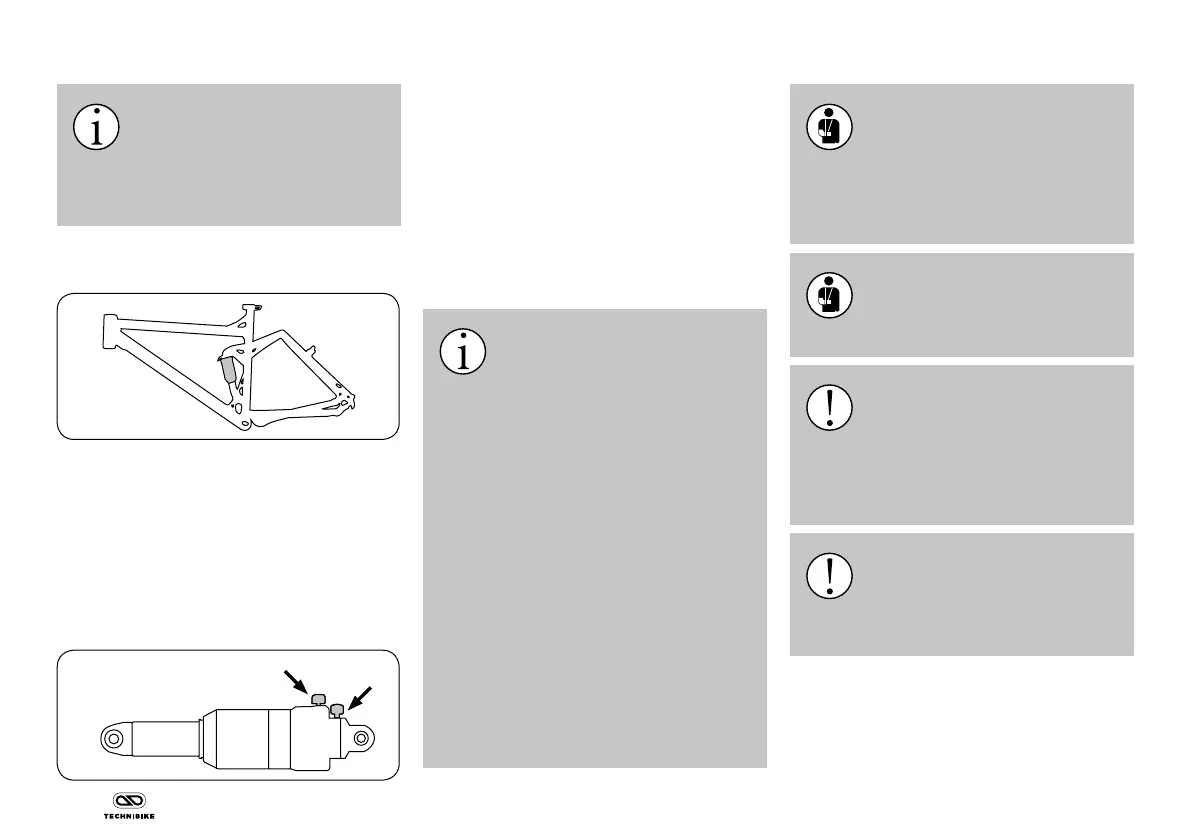

Here is a depiction of a typical spring element:

Adjusting spring

stiffness

Adjusting

damping

For detailed information, please read the instruc-

tions supplied by the manufacturer.

A suspension part may only be adjusted according

to the manufacturer’s operating manual. In general,

the suspension part should noticeably “give” when

riding over uneven surfaces, but not reach the end

of the travel. A suitable basic setup would see the

suspension pushed in around 10 – 15 % (cross

country), 15 – 20 % (touring) or 25 – 33 % (endu-

ro, freeride, downhill) of the spring travel when

the rider is sitting normally on the bicycle.

Avoid washing your bicycle with a

high-pressure cleaner as the clean-

ing uid can penetrate sealed areas

due to the high pressure and then eventually

destroy them.

The shock absorber’s sliding pistons and gas-

kets should be carefully cleaned with a soft

cloth as part of your regular bicycle clean-

ing routine. Spray lubricant on the running

surface of the shock absorbers and gaskets

helps keep the system working effectively.

Special spray lubricant is available specical-

ly for this purpose, e.g. from Brunox

®

.

You should regularly check the links of the

rear fork for play. Grip the frame securely

and attempt to move the rear wheel side-

ways. You can also test for play in the shock

absorber attachment by rapidly lifting and

dropping the rear wheel. If you a) notice play

anywhere or b) hear rattling, you should im-

mediately take your bicycle to be checked

by a specialist retailer.

Avoid riding the bike until it has been repaired.

The functionality and secure t of

the suspension parts are vital for

your safety! Clean and check your

full suspension bicycle on a regular basis!

Warm water with a little washing up liquid or

light cleaning agents are suitable for clean-

ing this part of the bicycle.

Tighten all screws to the recom-

mended torque. Otherwise the

screws could break and parts could

fall off (see page 25).

Full suspension bicycles are not

suitable for use with trailers and

child bike trailers!

The bearings and attachments are not de-

signed to withstand this sort of force. This

could result in strong wear and breaks with

serious consequences.

If you have a full suspension frame

with a short seat tube which is open

at the bottom, the seat post can only

be lowered to the point that it does not touch

the spring element when it uses its full travel.

Loading...

Loading...