27

How to use carbon components

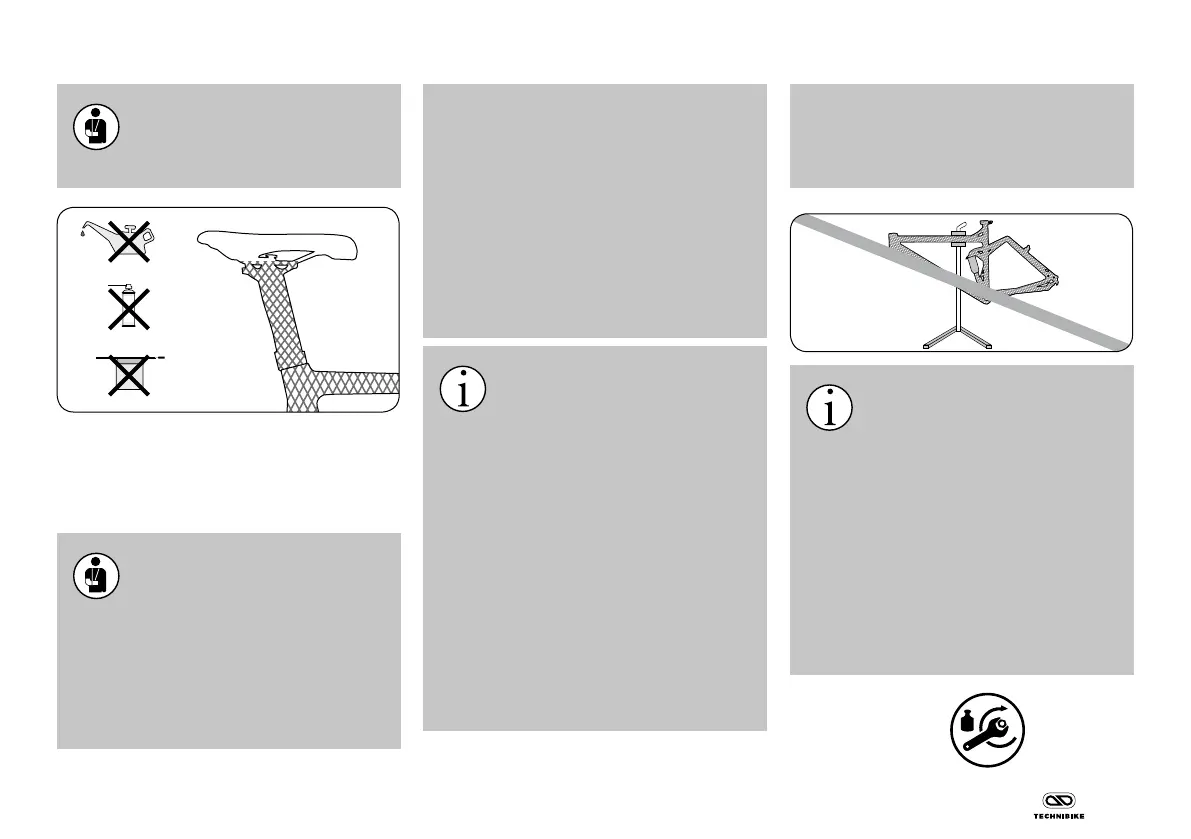

If you have a carbon frame or parts,

these should not be applied with

grease or oil. Please use special as-

sembly paste for carbon parts.

Carbon is a material which requires special han-

dling and care during construction, servicing, rid-

ing, transport and storage.

Properties of carbon

Carbon parts cannot be bent, dent-

ed or misshapen after an accident/

fall. If this is the case, it is possible

that the bres have been destroyed or have

broken off, e. g. within the part, which is not

visible from the exterior!

Therefore, it is vital to regularly check car-

bon frames and other carbon components

very carefully, especially after a fall or an

accident.

• Look for splinters, tears, deep scratches,

holes or other changes in the carbon surface.

• Check if the parts have got softer or less

stiff than usual.

• Check if individual layers (paint, nish or

bres) come off.

• Listen for any cracking or other usual

sounds.

If you are not completely certain that your

bicycle is in perfect condition, please allow a

specialist retailer to check the affected car-

bon parts!

Some carbon components require

lower torques than metal parts. Ex-

cessive torques can lead to hidden

damage, which is possibly not visible from

the outside. Frames or components can

break or warp to such an extent that you

could fall. Therefore please always adhere

to the instructions supplied by the manufac-

turer or ask for advice from a specialist. Use

a torque spanner to ensure that you get the

required torque. Carbon parts may not be

applied with grease or oil. Special assembly

paste is available for assembling and safely

securing carbon components with a low

mounting torque.

Never expose carbon parts to high temper-

atures! Even in the back of cars, the sun’s

rays can generate such a heat that it can put

the safety of carbon parts at risk.

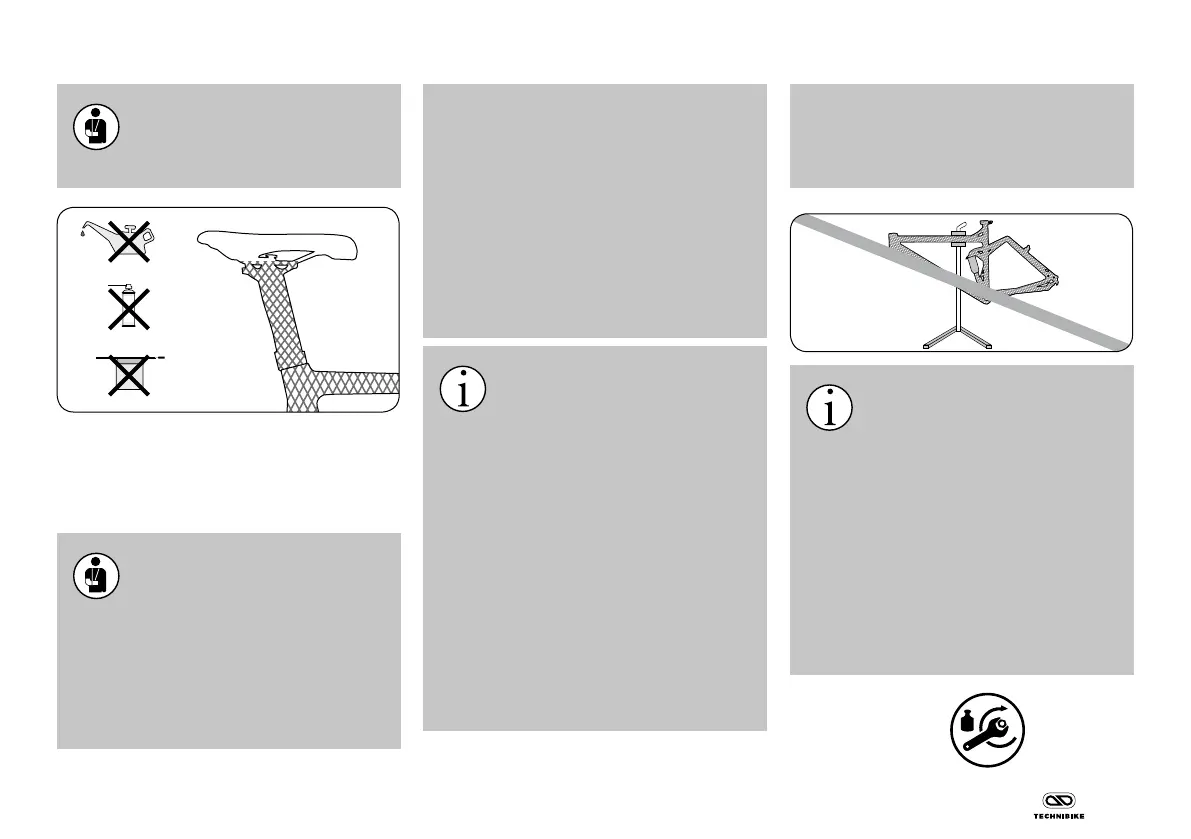

Do not clamp a carbon frame directly into a

work stand, instead you should secure it by

the seat post. If the seat post is also made

of carbon, use another tube made of metal.

The following components and sec-

tions of carbon parts should be

checked regularly (at least every

100 km or 62 miles) for irregularities such as

cracks, breaks or surface changes, as well

as after any accident or fall involving the bi-

cycle: Transition area of the threaded bush-

ing of the drink holder, slot of the dropouts,

bearing areas in full-suspension frame, sus-

pension mounting elements on the main

frame and rear suspension, seat clamp, de-

railleur hanger, derailleur clamp area, disc

brake mounting or brake boss, press-t area

of the headset as well as the threads of the

bottom bracket cups.

Carbon =

Loading...

Loading...