Operation & Maintenance Manual

CD-135 / CD-155

OM-02-02

Revision no.:

Revision date:

Chapter:

Issue:

Issue date:

Page:

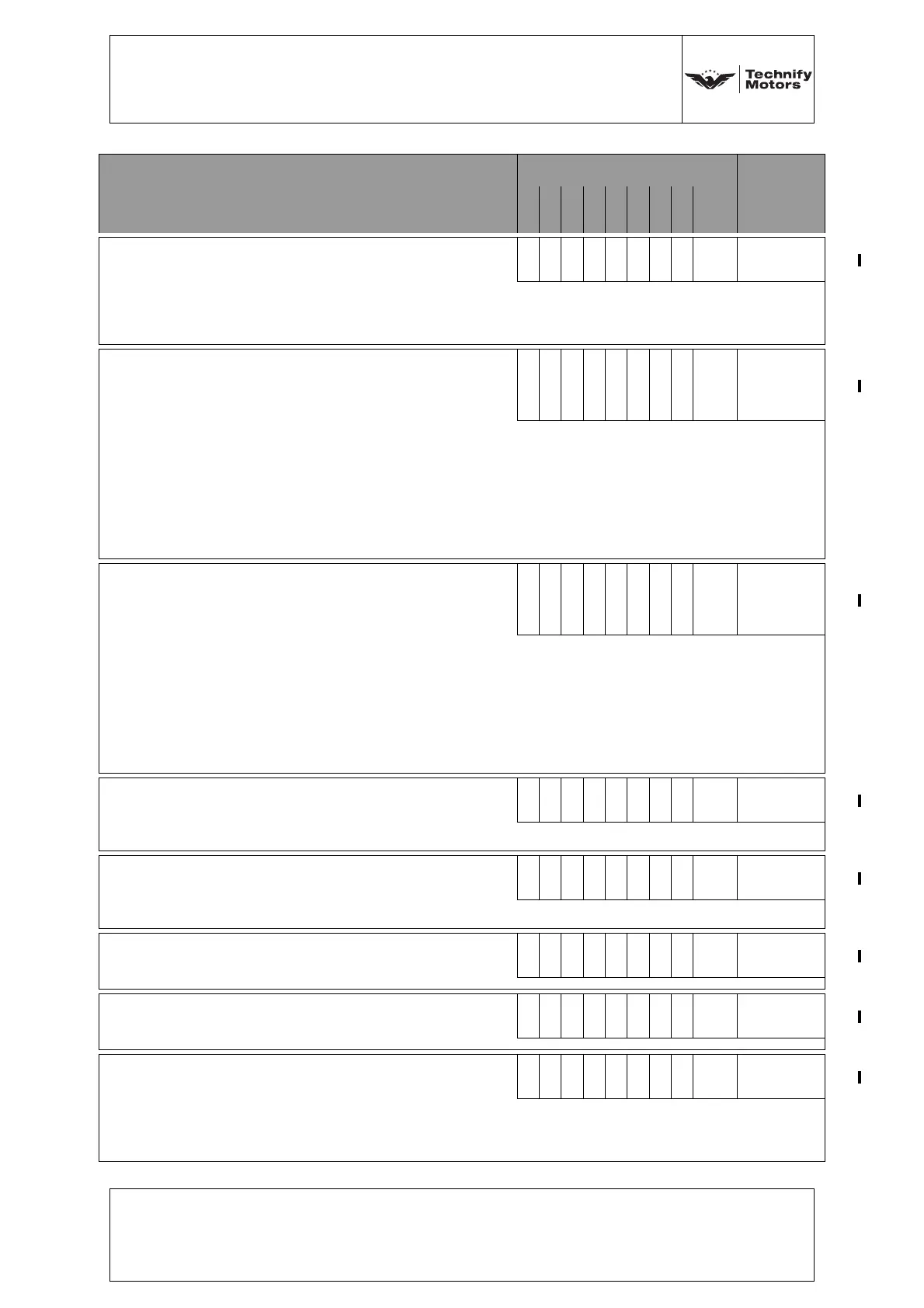

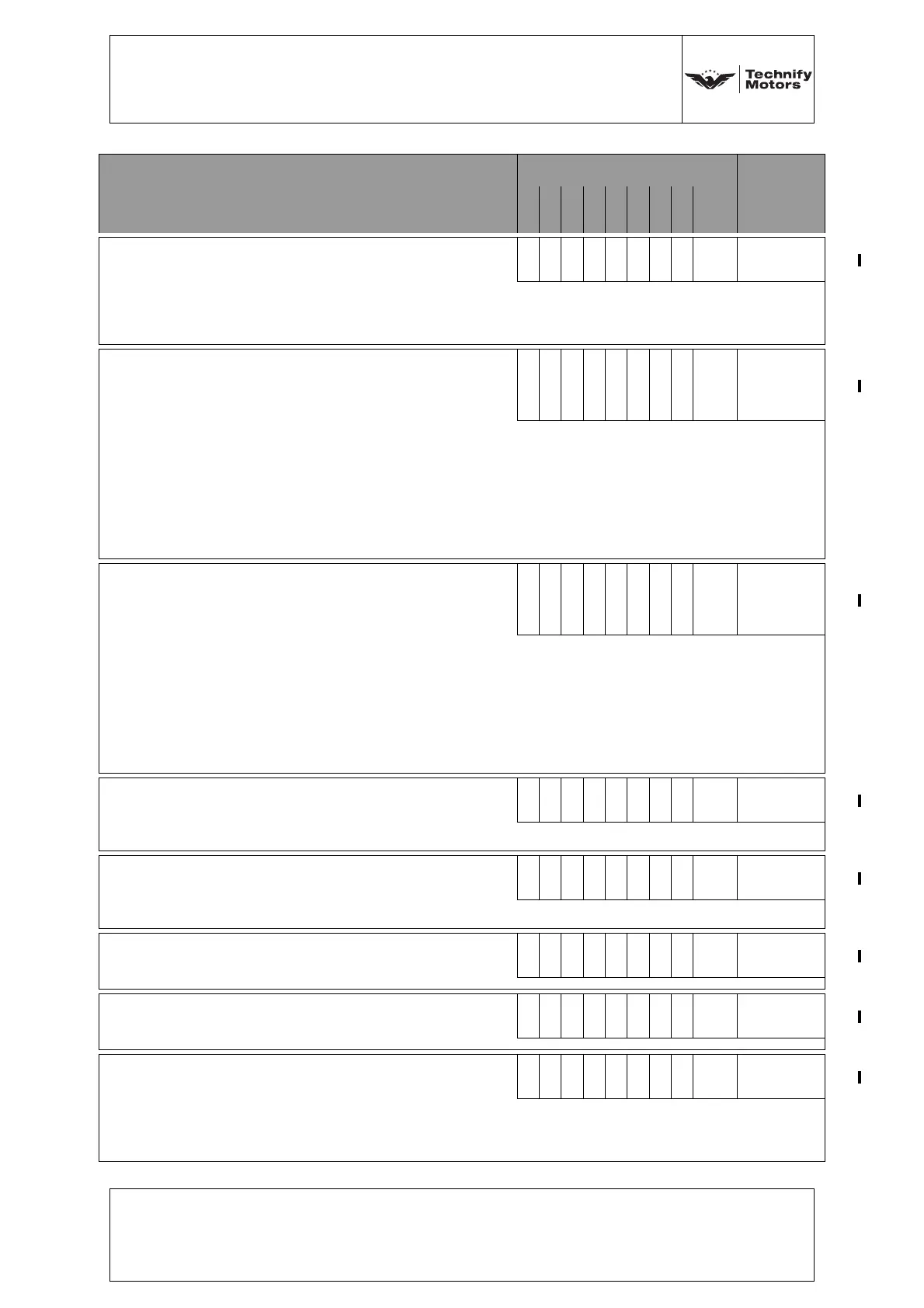

Content:

Checklist

4

17.04.2015

3

8

5

20.07.2016

Engine Maintenance Checklist - General

Perform an engine test run

according to Chapter 4, Section 4.4.2, Page 5 of this

Manual and read out the FADEC.

E-mail both the Real Time Log Files and Event Log Files

to Technify Motors GmbH

(refer to Chapter 6, Annex 10 of this Manual).

xxxxxxxx

Exchange the engine oil and the oil filter

(refer to Chapter 6, Annex 5 of this Manual);

A sample of the oil and the used oil filter should be

labeled, stored in a clean container and made available to

Technify Motors GmbH on request for the complete

engine life time. The sample will be required for a later

long-run analysis. The label must show the aircraft serial

number, registration number, engine serial number,

operation time and date.

Quantity of oil to be taken for sample: 100ml

xxxxxxxx

every

12 month

Exchange gearbox oil and the gearbox oil filter

(refer to Chapter 6, Annex 13 of this Manual);

A sample of the oil and the used gearbox oil filter should

be labeled, stored in a clean container and made

available to Technify Motors GmbH on request for the

complete engine life time. The sample will be required for

later long-run analysis. The label must show the aircraft

serial number, registration number, engine serial number,

operation time and date.

Quantity of oil to be taken for sample: 100ml

xxxxxxxx

every

12 month

Check the presetting of the proportional pressure

reducing valve

(refer to RM-02-02, Chapter 72-10.05 or Chapter

72-10.16)

xxxxxxxx

Replace air filter

When replacing the air filter check carefully that no

foreign objects are in it.

xxxx

Inspect fuel feed pump,

except 05-7312-K0073xx, 05-7312-K0133xx

(refer to Chapter 6, Annex 18 of this Manual)

xxxxxx

Inspect fuel feed pump

05-7312-K0073xx, 05-7312-K0133xx

(refer to Chapter 6, Annex 18 of this Manual)

xxx

Replace high-pressure pump

(refer to Chapter 6, Annex 11 of this Manual)

Replacement of the high-pressure pump at every 300

operating hours is only applicable if TS-1 jet fuel is being

used.

xxxxxx

Inspection Items

Interval

(Engine operation hours)

Initials

100

200

300

600

900

1200

1500

1800

Time

Loading...

Loading...