POWER SUPPLY

The NT935 WS control unit can be supplied by 85 to 260 Vac-Vdc, 50/60 Hz irrespectively of polarity in Vdc

(terminals 40-42).

This is obtained thanks to the use of a tested power supply unit, newly designed and manufactured, that frees installers from

worrying about the correct Vac and Vdc supply.

The ground must always be connected to terminal 41.

When the unit is supplied directly by the secondary of the transformer to protect, it can be burnt out by strong overvoltages.

This happens if the main switch is closed and the transformer has no load (blank test).

The above-mentioned problems are much more evident when the 220 Vac voltage is taken directly from the

transformer secondary bars and there is a fixed capacitor battery to phase the transformer itself.

.

If an existing control unit must be replaced with a new one, to guarantee its correct and safe operation, the

sensor/relay/supply connecting terminals must be replaced with the new terminals supplied.

ALARMS AND VENTILATION

Carry out the electrical connections on the removable terminal blocks only after disconnecting them from the unit.

When the control unit is in one of the modes mentioned below, it does not monitor the temperature and the relays are all

blocked. The fault contact switches and the fault LED flashes.

• Vis. programming display

• PRG Programming

• Relay test

The ALARM and TRIP relays switch only when the set temperature thresholds are exceeded.

The FAULT contact, programmed in failsafe mode (default YES), opens (11-12) when the equipment is supplied only if

the unit detects no fault on switching on, and stays in this condition until one of the following events occurs:

• Data memory fault (Ech message).

• Pt100 sensor fault (FCC short-circuited sensor, FOC interrupted sensor or Fcd quick temperature increase)

• CAL damage to the measurement circuit.

• Insufficient supply voltage.

• During the power on reset after programming (PRG), displaying the data (VIS) and test relay.

The FAULT failsafe can be disabled selecting FAULT failsafe "NO" see step 34-35 programming page 14.

NOTE: do not connect the FAULT relay to the transformer tripping circuit to avoid unwanted system interruptions.

FAULT AND RESET MESSAGE SEQUENCE

Find below the sequence of fault messages and RESET function condition.

1) ECH

2) CAL

3) FCD

4) ERR PT

The FAN1 and FAN2 contacts can be used to control the cooling fans, or they can be inserted in the conditioning system of the

transformer room, see paragraph cooling fan control on page 17.

NOTE: always disconnect the unit before performing any electrical connections.

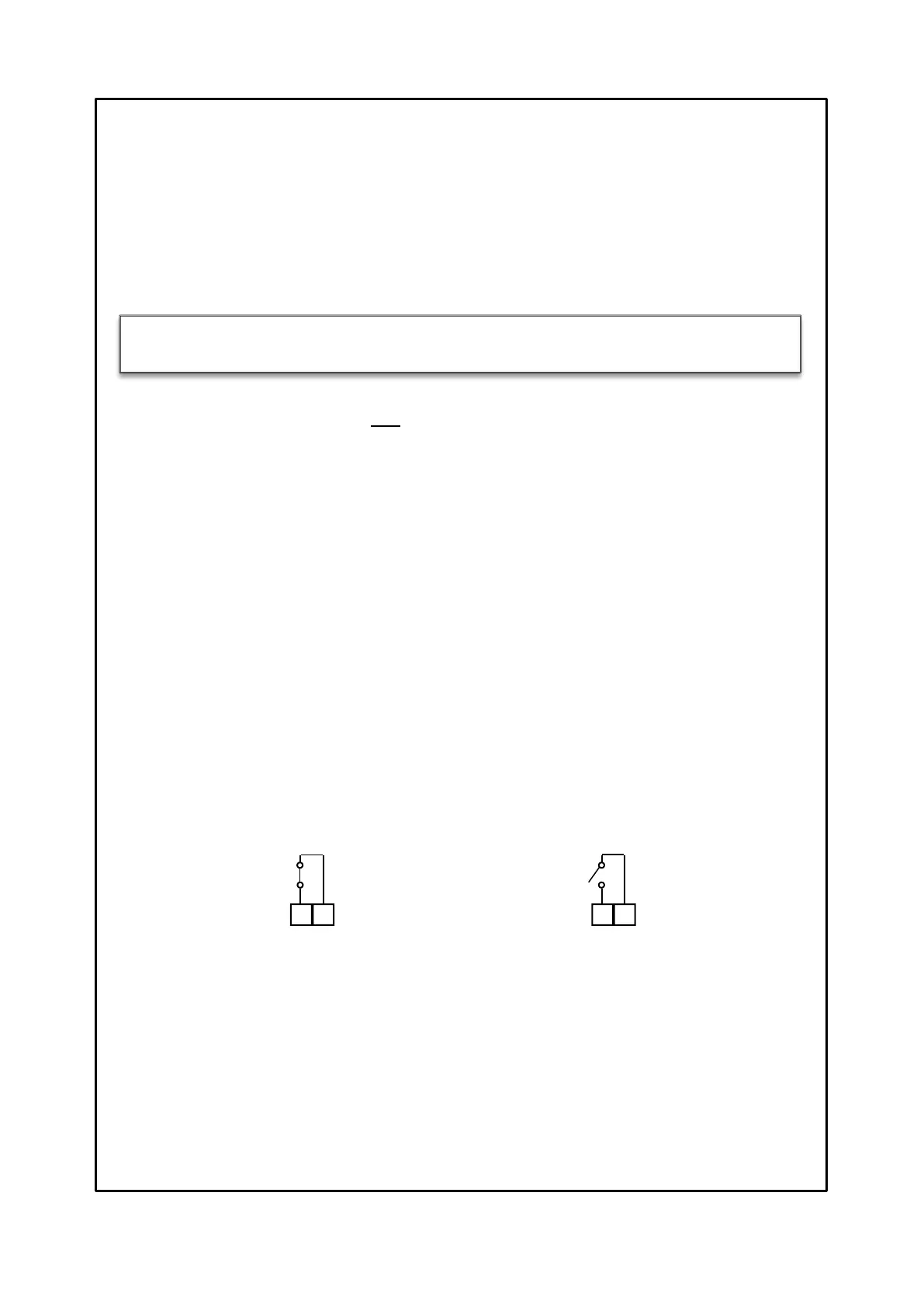

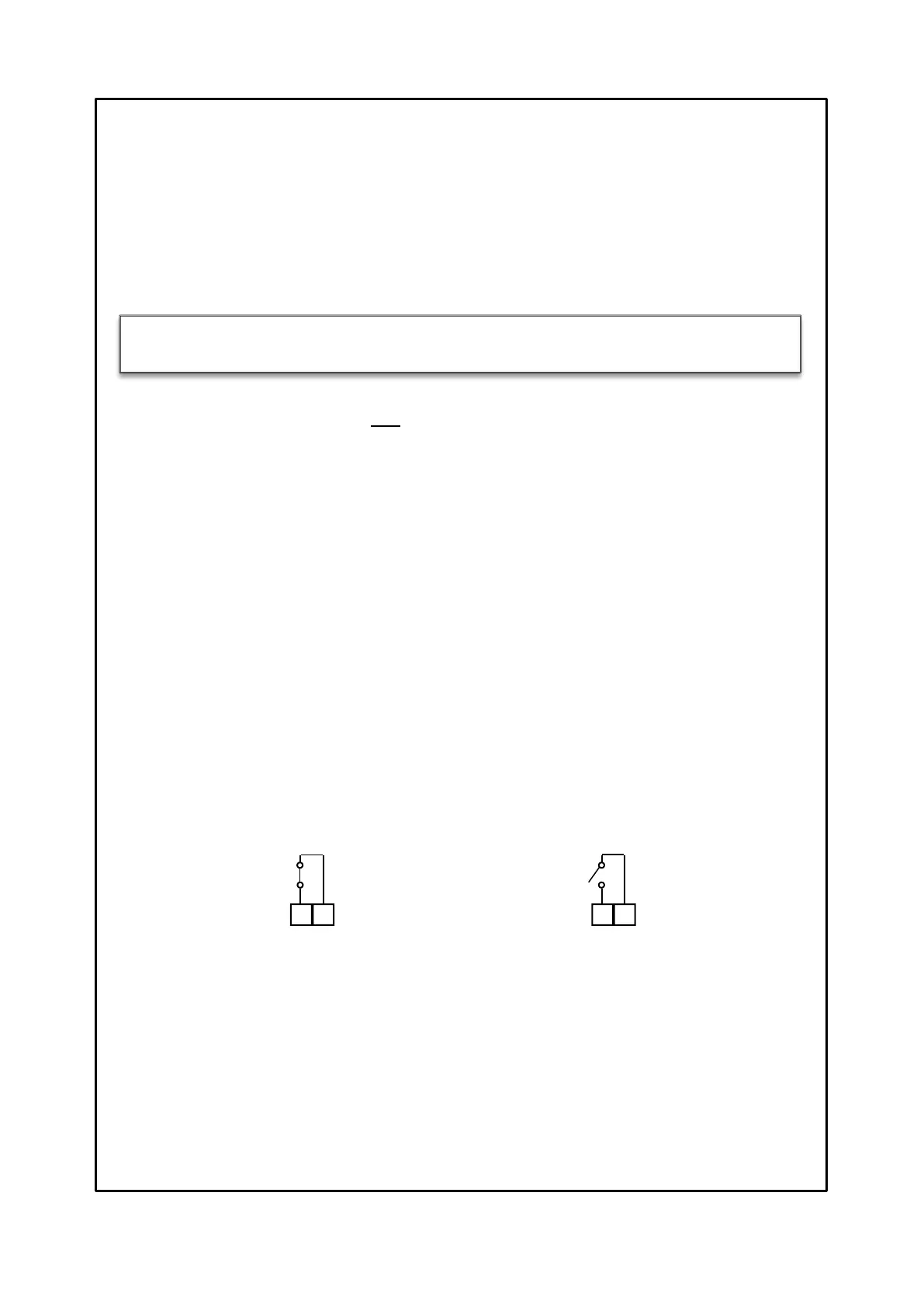

FAULT 11-12 NC: ALARM FAULT OR POWER OFF

FAULT 11-12 NO: POWER ON OR NO FAULT

FAULT CONTACT (failsafe active)

eeprom fault

measurement circuit fault

quick temp. increase fault

FCC or FOC sensor fault

erasable message

erasable message

resettable condition

non-resettable condition

To protect the control unit against line overvoltages, the PT-73-220 electronic arrester, designed by TECSYSTEM S.r.l.

for this specific purpose, is recommended. Alternatively, it is advisable to use 110 V AC supply voltages or, even better,

110 VDC.

Loading...

Loading...