7-12

CAUTION: NEVER ATTEMPT TO STRAIGHTEN A

BENT CRANKSHAFT.

Inspect the crankshaft oil galleys for blockage or

obstruction. (Illust. 7-32)

CAMSHAFTS

Check the camshaft bearing surfaces for wear using a

micrometer. Inspect the cam lobes for scoring or

excessive wear.

Specifications English Std. Metric

Camshaft Bearing Diameter .6235 15.836

.6240 15.849

Cylinder and Flange .6245 15.862

Camshaft Bearing Diameter .6255 15.887

7-32

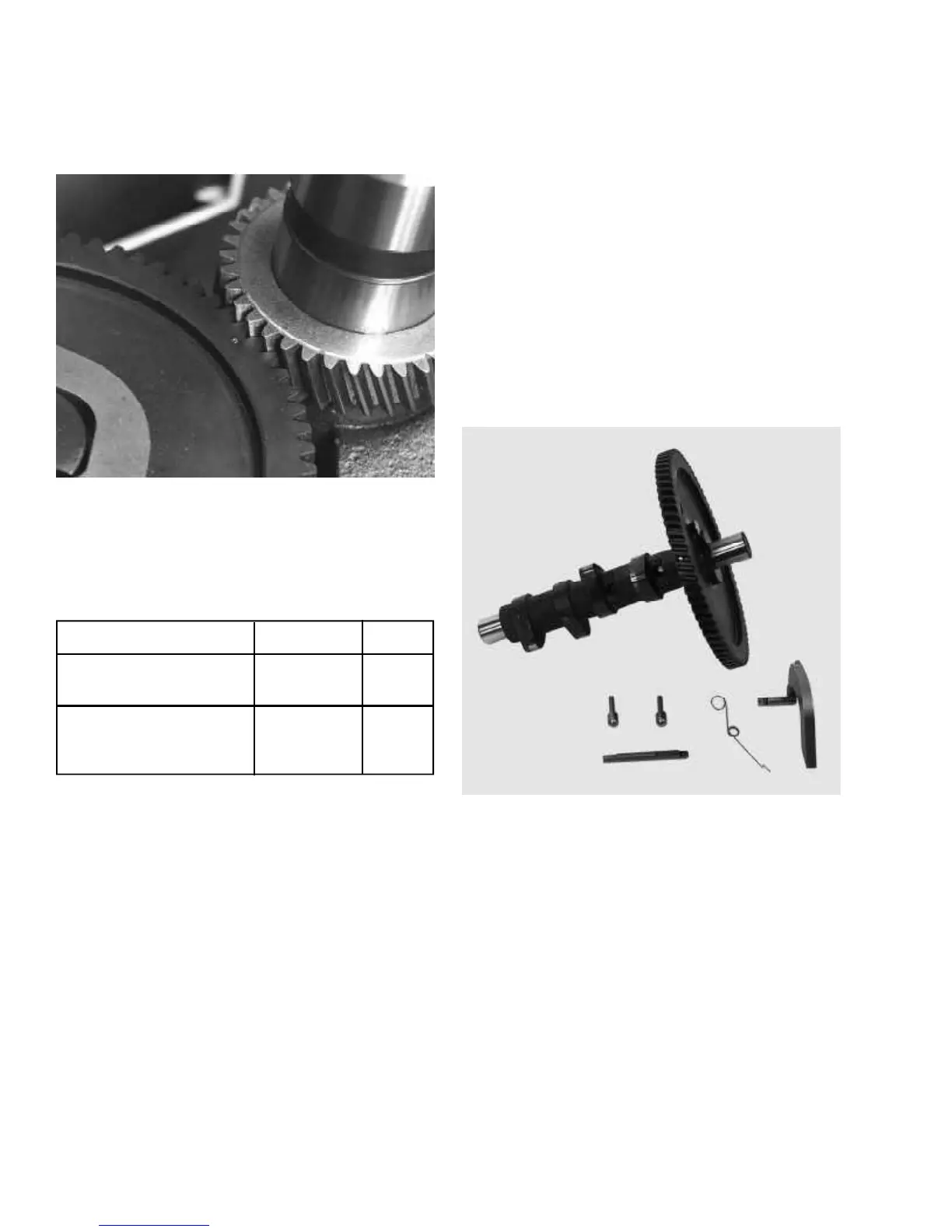

MECHANICAL COMPRESSION RELEASE

The Mechanical Compression Release (MCR)

incorporates pins located in the camshaft. The pins

extend above the exhaust cam lobes, lifting the valve

and relieving engine compression for easier starting.

When the engine starts, centrifugal force moves the

weight outward and the pin will drop back down. The

engine will now run at full compression.

The components of the MCR except for the internal pins

are serviceable. When servicing the MCR be cautious

not to misplace the pins, as a new camshaft would be

necessary.

Clean the camshaft with solvent and dry all parts with

compressed air. Make sure that the pins, weight and

shaft of the mechanical compression release are

operating freely and smoothly. (Illust. 7-33)

7-33

Loading...

Loading...