7-5

VALVES

Specification English Metric

Min Valve Stem Dia.

Intake .3095 7.861

Exhaust .3080 7.823

Min Valve Face .031 .794

Max Valve Guide .316 8.026

Inside Dia.

Valve condition is critical for proper engine performance.

The valves should be inspected for both sealing, and

wear.

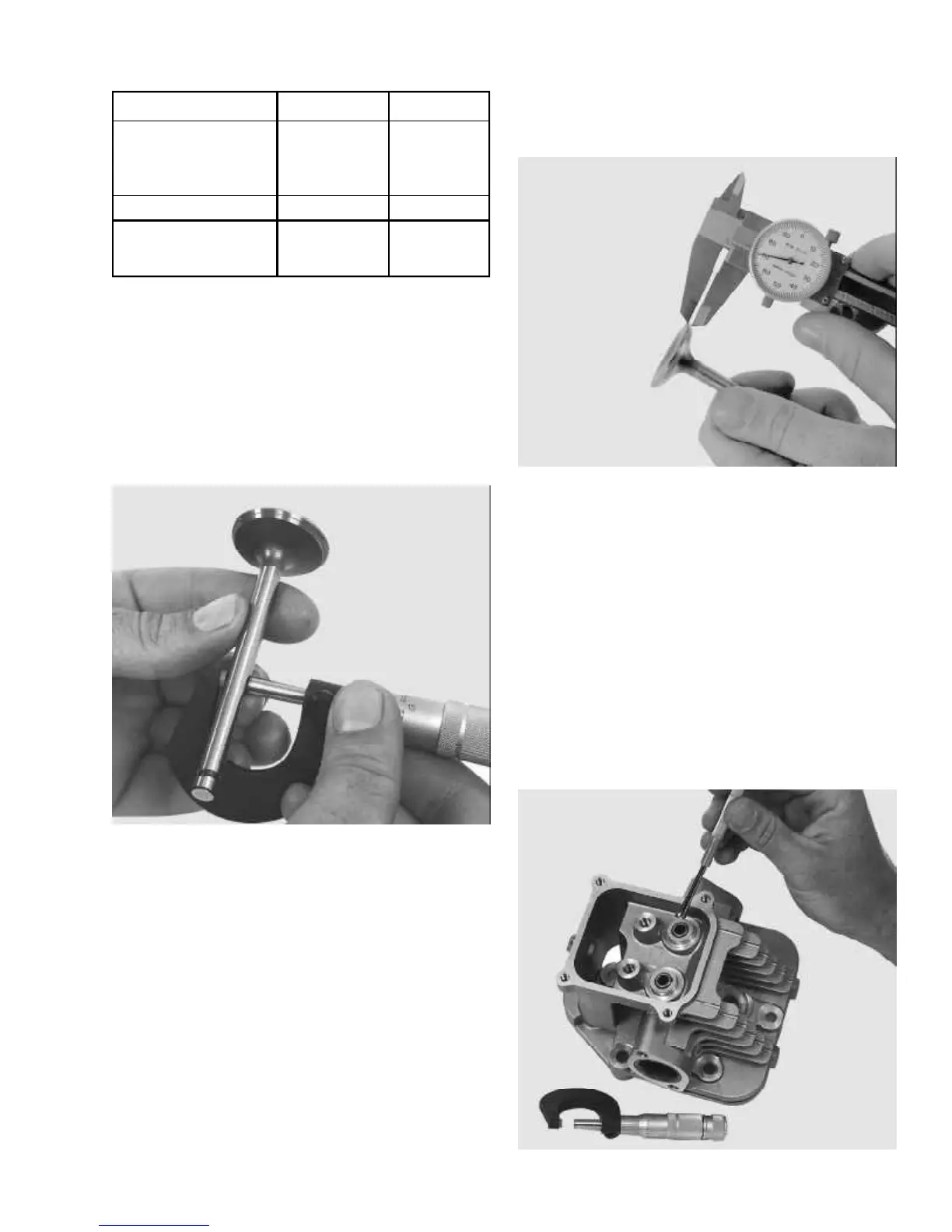

Clean and inspect each valve face for distortion or

corrosion. Check the valve stem for wear. (Illust. 7-13)

Replace valve if stem diameter is less than: Intake .3095

(7.861 mm) Exhaust .3080 (7.823 mm).

If the valves have been checked and are in a usable

condition, the valve face should be ground at a 45 degree

angle. If after grinding the valve face the top margin is

less than .03125 (.794 mm), the valve should be

replaced. (Illust. 7-14)

7-13

7-14

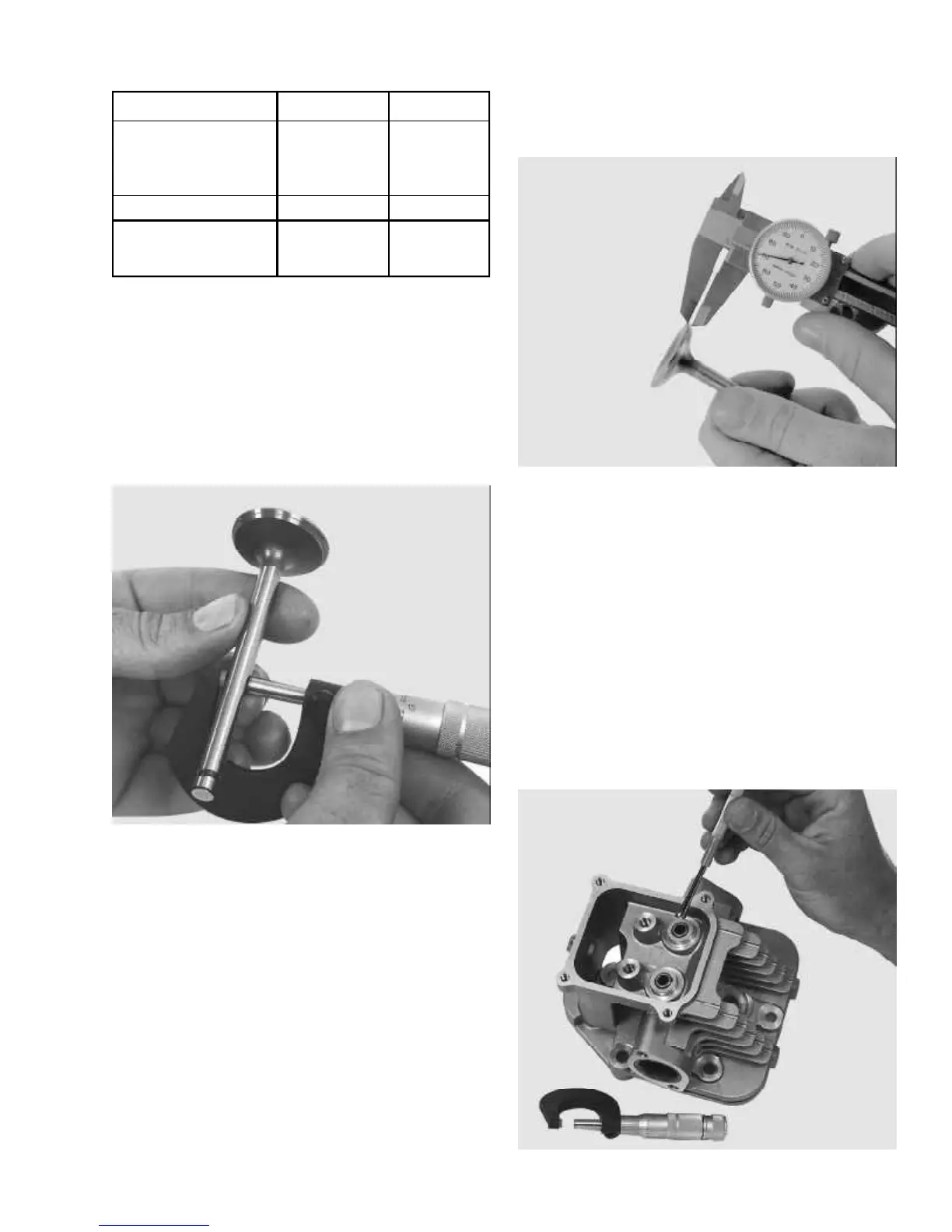

7-15

The valves are not identical. Valves marked “EX” or “X”

are installed in the exhaust valve location. Valves marked

“I” are installed in the intake valve location. If the valves

are unmarked, the smaller valve (head) is installed in

the exhaust valve location.

VALVE GUIDES

The valve guides are not replaceable but should be

checked for wear. Using a split ball gauge and a

micrometer, measure the inside diameter of the valve

guides. (Illust. 7-15) This measurement should not

exceed .316 (8.026 mm) If a guide is found to be out of

specification the cylinder head will need to be replaced

as a complete assembly.

Loading...

Loading...