6-3

SERVICE

SPARK PLUG SERVICE

Spark plugs should be removed, inspected and adjusted

periodically. Replace the spark plugs every 100 hours or

annually.

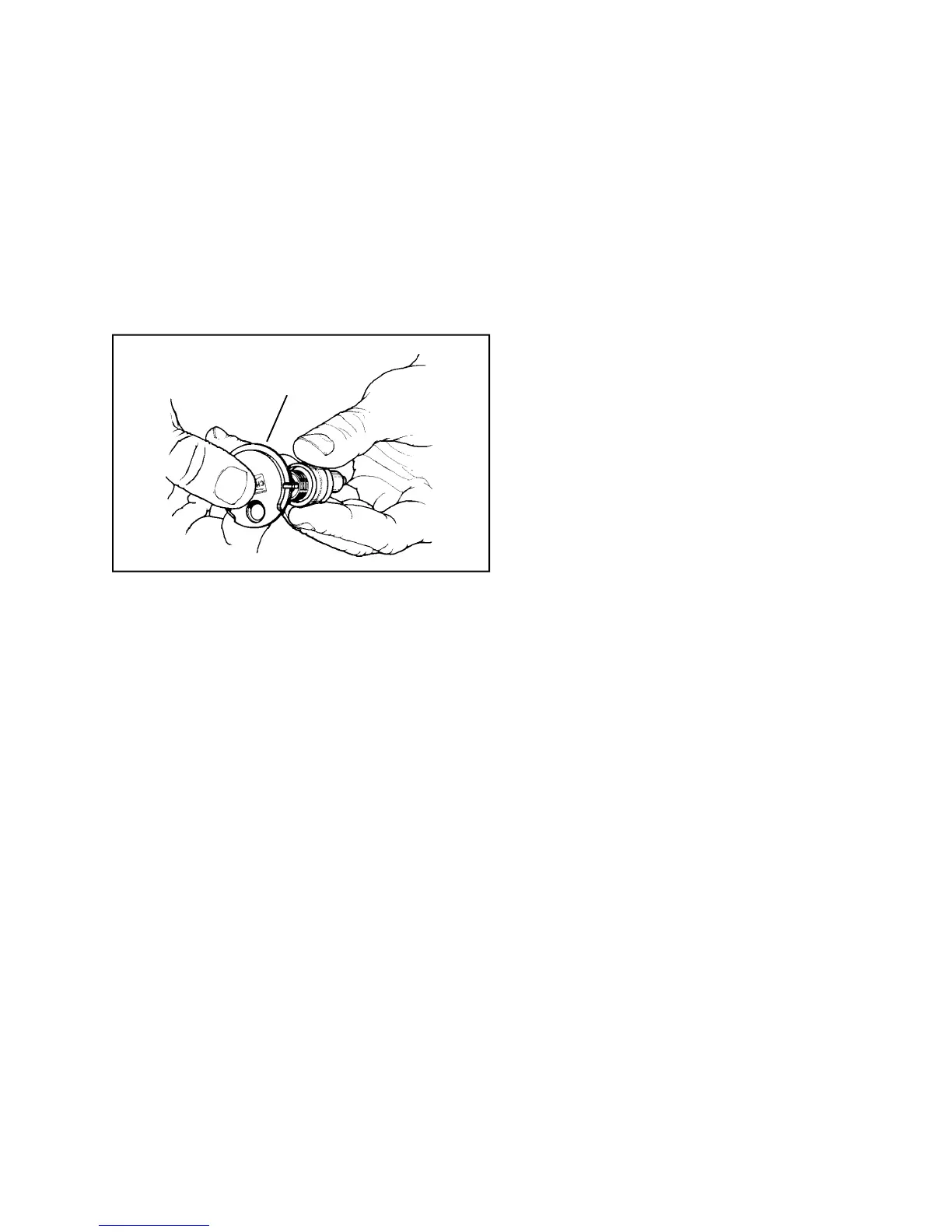

Check the air gap(s) with a spark plug gap gauge and

adjust accordingly. Set the spark plug gap at .030" (.762

mm). (Illust. 6-5)

6-5

CONDITIONS CAUSING FREQUENT

SPARK PLUG FOULING

1. Air cleaner is restricted. (Replace)

2. Partially closed choke shutter. (Check operation)

3. Poor grade of gasoline. (87 octane minimum)

4. Improper fuel. (Old, stale or mixed)

5. Restricted exhaust system. (Remove and inspect

muffler for restrictions or loose baffles)

6. Incorrect spark plugs. (Check reach and number)

7. Incorrect spark plug gap. (Adjust gap)

8. Oil level is too high, or the breather is restricted.

9. Worn piston rings.

10. Weak ignition system. (Air gap to wide, partially

grounding wires or faulty safety switches)

IGNITION TIMING

In order for an engine to run efficiently, the spark must

ignite the compressed air-fuel mixture when the piston

is in a specific position to deliver maximum power. This

position is known as Before Top Dead Center (BTDC). If

the mixture is ignited too soon, kickback can be

experienced due to pre-ignition. If the mixture is ignited

too late, loss of power can be experienced due to retarded

spark. A partially sheared or the wrong flywheel key can

cause kickback, loss of power, or an inability to start the

engine. Check the flywheel key if one of these symptoms

exist. See Chapter 7 under “Service” for the disassembly

procedure.

Replace the plug if the points on the base of the plug are

pitted or burned, or if the porcelain is cracked anywhere.

When reinstalling the plug make sure it is clean and free

of all foreign material.

NOTE: NEVER use a sand blaster to clean plugs,

microscopic particles left in the plug can score the engine

cylinder during operation. Use a solvent and a wire brush

to clean. Using eye protection, blow out thoroughly with

compressed air.

Replace the spark plug with the proper spark plug.

Consult the parts breakdown for the spark plug to be

used in the engine being serviced.

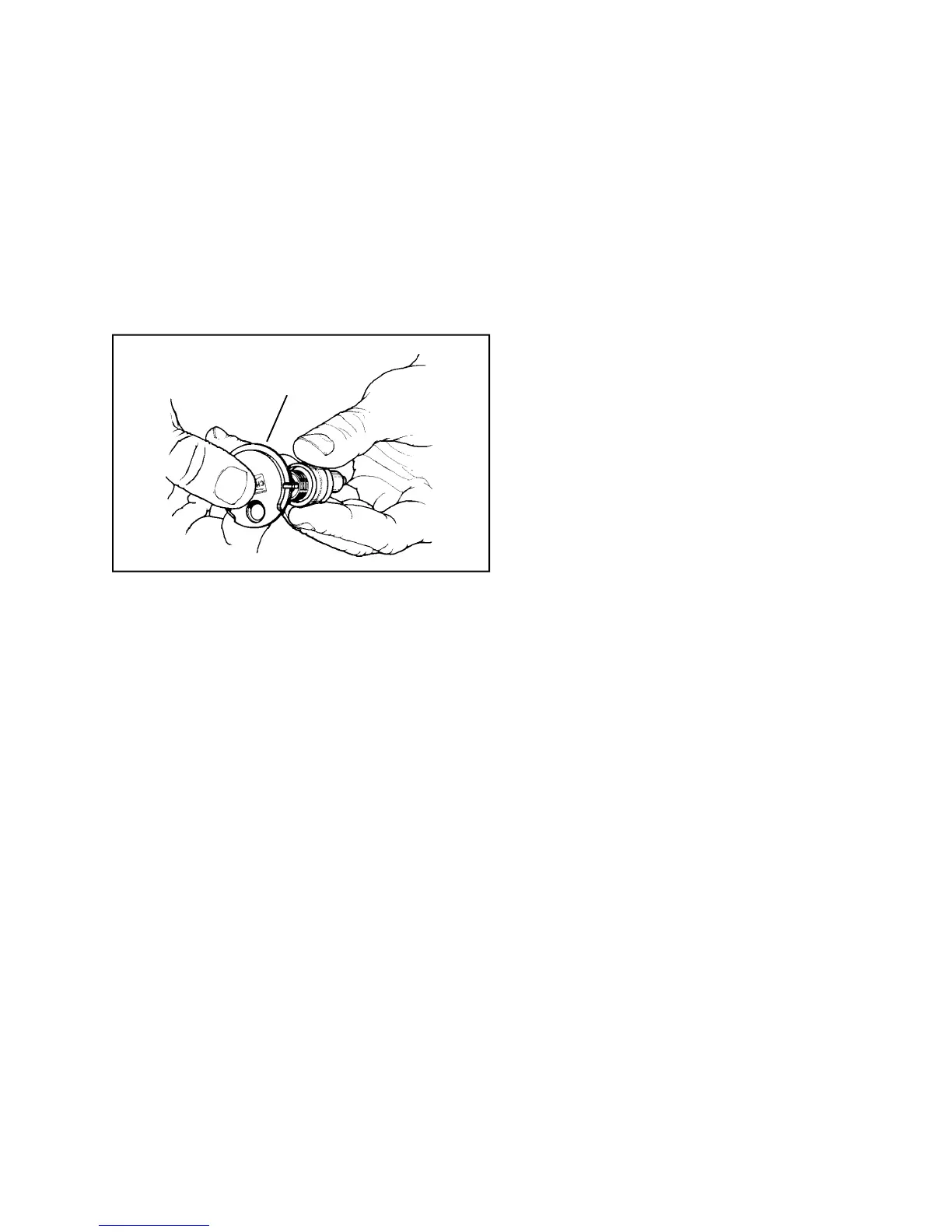

Install the spark plug, being careful not to cross thread.

Tighten the spark plug to 21 foot pounds (28 Nm) of

torque. If a torque wrench is not available, turn the spark

plug in as far as possible by hand, then use a spark plug

wrench to turn the plug 1/2 turn further. If installing a

used plug, only 1/8 to ¼ turn after seat is needed.

GAP GAUGE

.030”

(.762 mm)

Loading...

Loading...