7-9

RINGS

Specification English Std. Metric

Piston Ring .002-.005 Top .051-.127 Top

Side Clearance .001-.004 Center .025-.102 Center

.001-.004 Bottom .025-.102 Bottom

Piston Ring .007-.015 Top .178-.381-Top

End Gap .013-.021 Center .330-.533 Center

.005-.013 Bottom .127-.330 Bottom

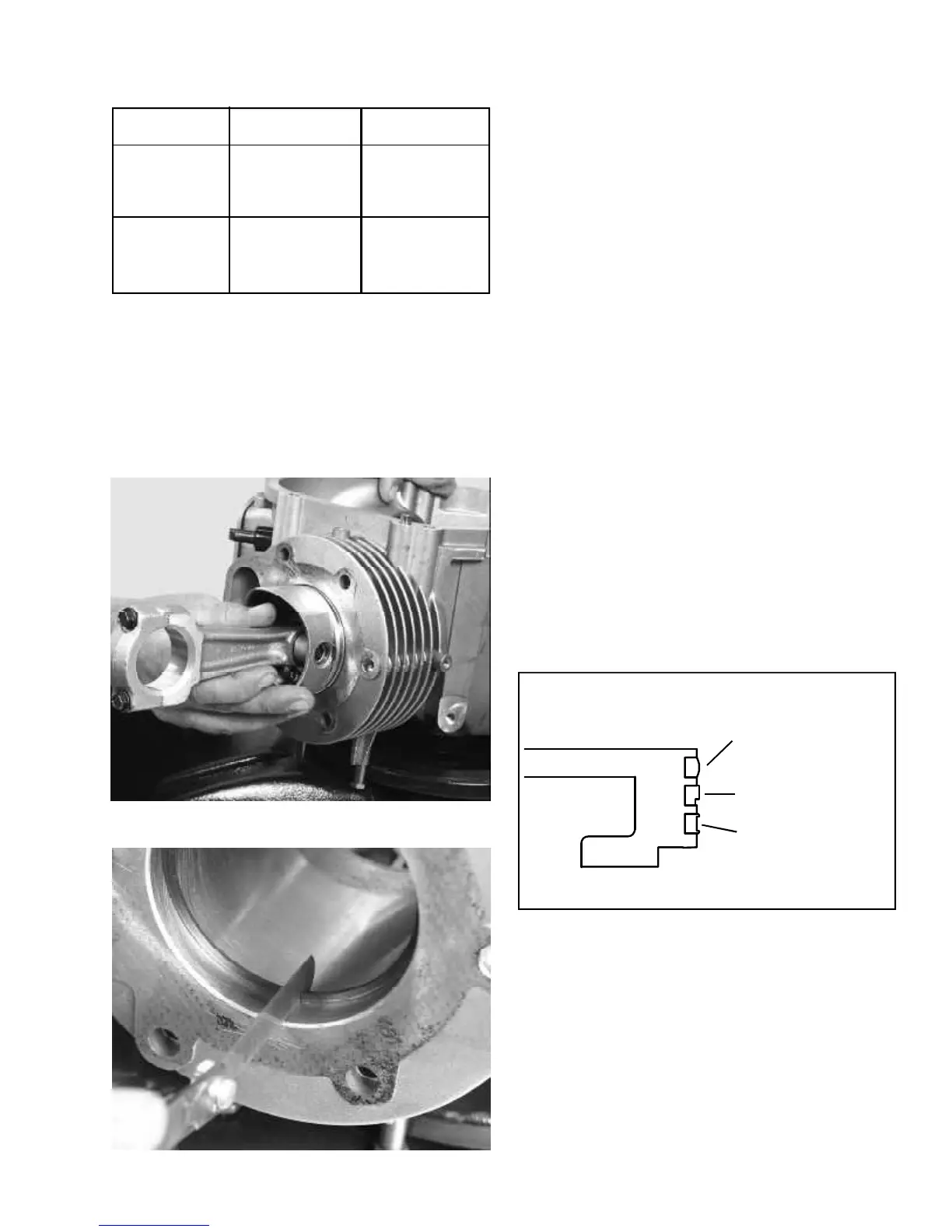

After the cylinder bore diameter has been checked and

is acceptable to rebuild, the ring end gap should be

checked using new rings. Place a new compression ring

squarely in the center of the ring travel area. Use the

piston upside down without rings to push the ring down

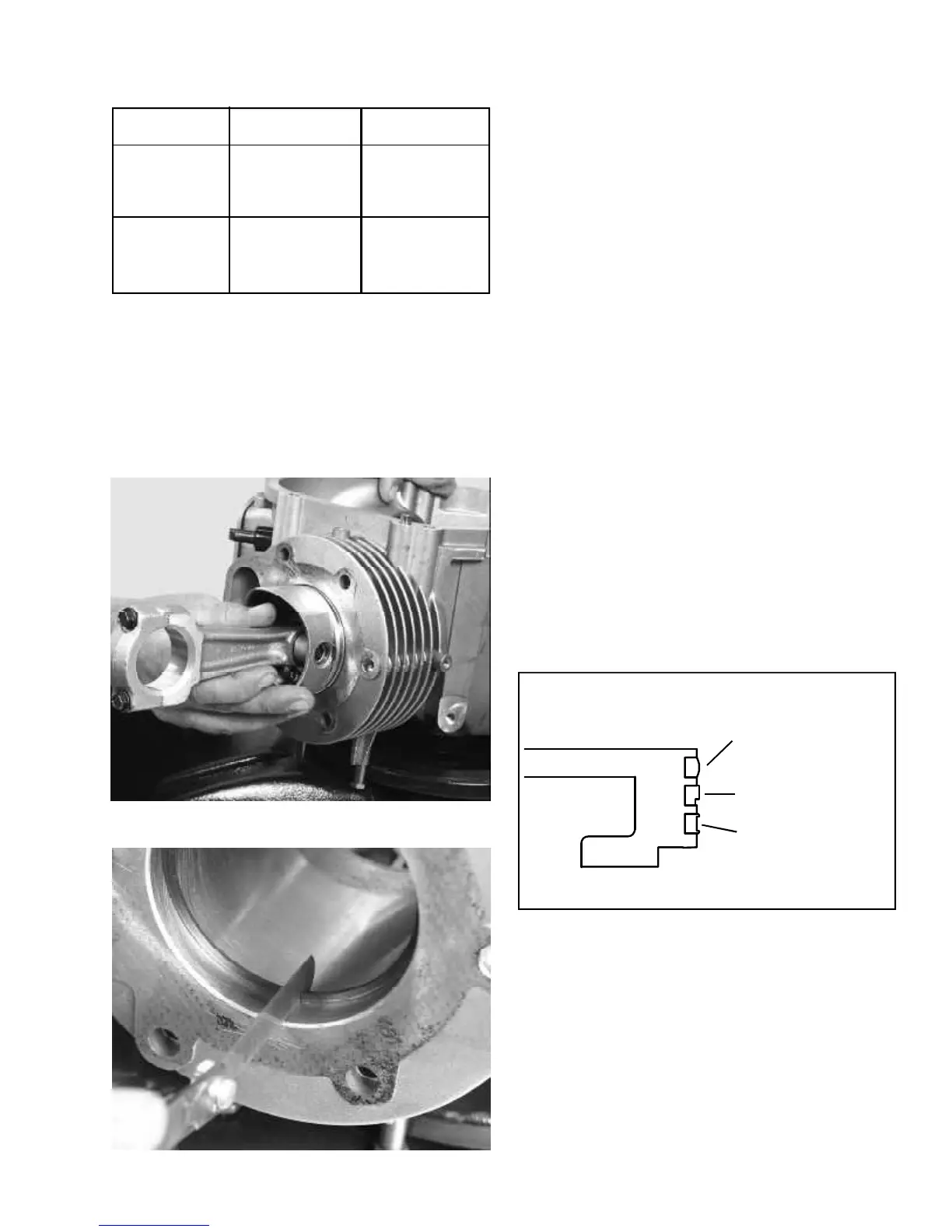

in the cylinder. (Illust. 7-26) Measure the gap with a feeler

gauge. (Illust. 7-27) The ring end gap must be within

specification to have adequate oil control.

7-26

7-27

NOTES:

1. A difference exists in piston ring end gaps between

the upper and center compression rings. Check the

specification table for the appropriate ring end gap.

2. Use a ring expander (Tecumseh tool part number

670117) to replace the piston rings. Do not spread

the rings too wide or breakage will result.

3. If installing new rings on a used piston, piston ring

side clearance must be checked.

4. Always replace the rings in sets.

5. Always install the piston and ring assembly in the

cylinder bore with the ring end gaps staggered.

6. When installing new rings in a used cylinder, the

cylinder wall should be de-glazed using a

commercially available de-glazing tool or hone with

380 grit stones. The crosshatch pattern should be

35-45 degree’s.

The emission ring set used on the TVT consists of two

compression rings and an oil control ring. The top

compression ring is barrel faced on the outside. This

ring can be installed with either side up. The second

compression ring will have an outside notch, which must

face down or towards the piston skirt. The oil control

ring can be installed with either side up. (Illust. 7-28)

7-28

EMISSION RINGS

1ST COMPRESSION RING

2ND COMPRESSION RING

3RD OIL CONTROL RING

Loading...

Loading...