7-1

CHAPTER 7. INTERNAL ENGINE AND DISASSEMBLY

GENERAL INFORMATION

This chapter covers the cylinder block, piston and rod

assemblies, cylinder heads, crankshaft, camshaft, valve

train, breather, cylinder cover, flywheel, and lubrication

systems. The internal governor systems are covered in

Chapter 4.

The TVT series engines are made using aluminum alloy

die cast around a cast iron cylinder liners.

LUBRICATION SYSTEMS

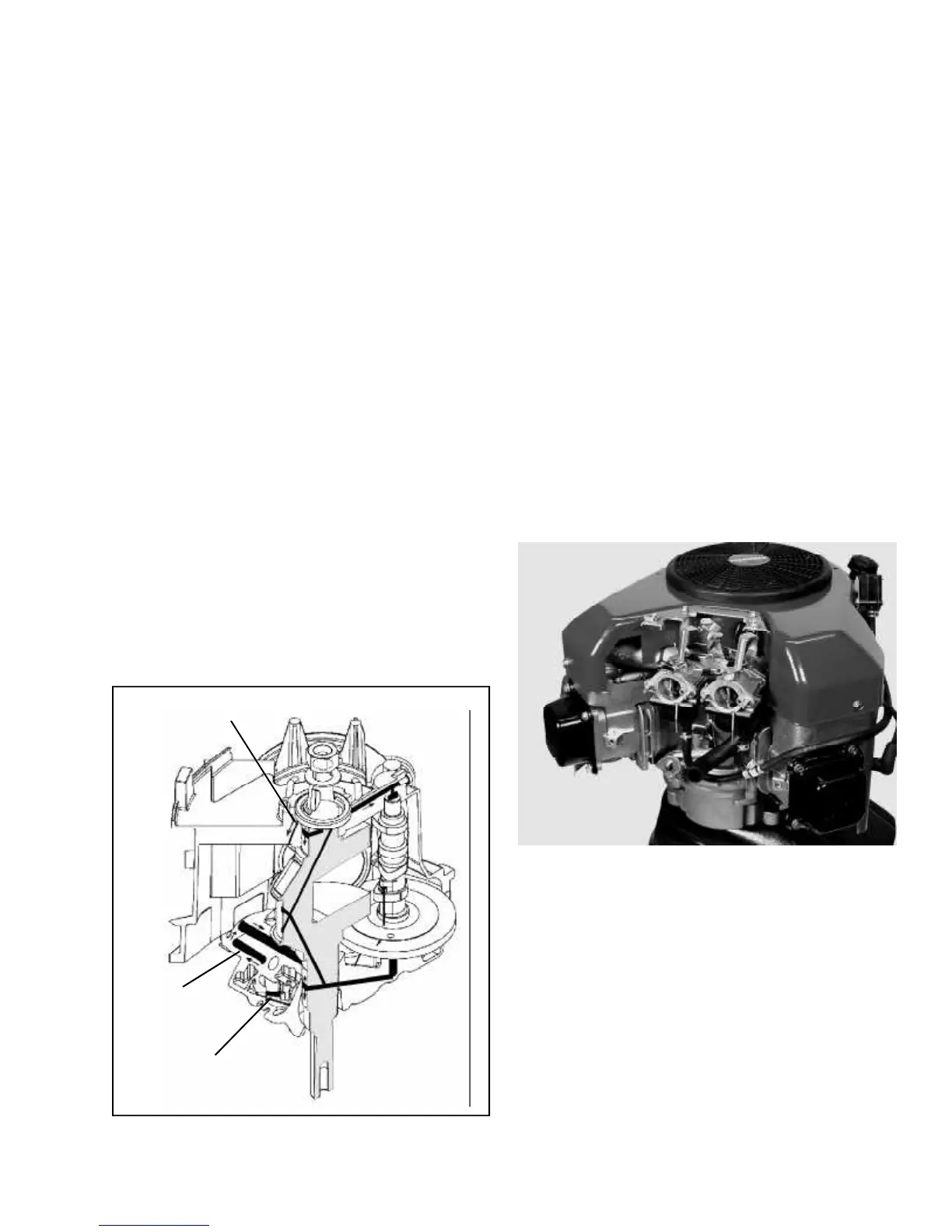

The TVT series engine uses an automotive type rotary

pump. Oil is drawn up to the pump from the pump inlet

screen area in the mounting flange cover/sump. Oil is

then pressurized and directed through the oil filter (if

equipped). This engine differs from OHV single cylinder

models in that the flange cover/sump bearings are also

pressure lubed.

From the oil filter the oil flows through the feed passages

to all crankcase bearings starting with the lower cam

and lower main bearing. The crankshaft has an undercut

around the bearing surface, which aligns with the oil feed

galley passage. The drilling of the crankshaft creates

the passage to the connecting rod bearings and the upper

main bearing. The upper camshaft bearing is fed oil by a

passage from the upper main bearing. See flow passage

(Illust. 7-1)

7-1

DISASSEMBLY PROCEDURE

1. Disconnect the high-tension leads from the spark

plugs. Remove the spark plugs. Evaluate each of

the spark plug(s) condition, for tips on areas

specifically in need of repair.

2. Drain the oil from the crankcase. Drain or shut off

the fuel supply and disconnect the fuel line at the

pump or carburetors.

3. Remove the negative battery lead. Remove the

positive cable to the starter. Unplug the charging/

ignition shut-off wires and the fuel shut-off solenoid

wires.

4. Remove the electric starter motor from the engine.

5. Disconnect the exhaust system from the engine.

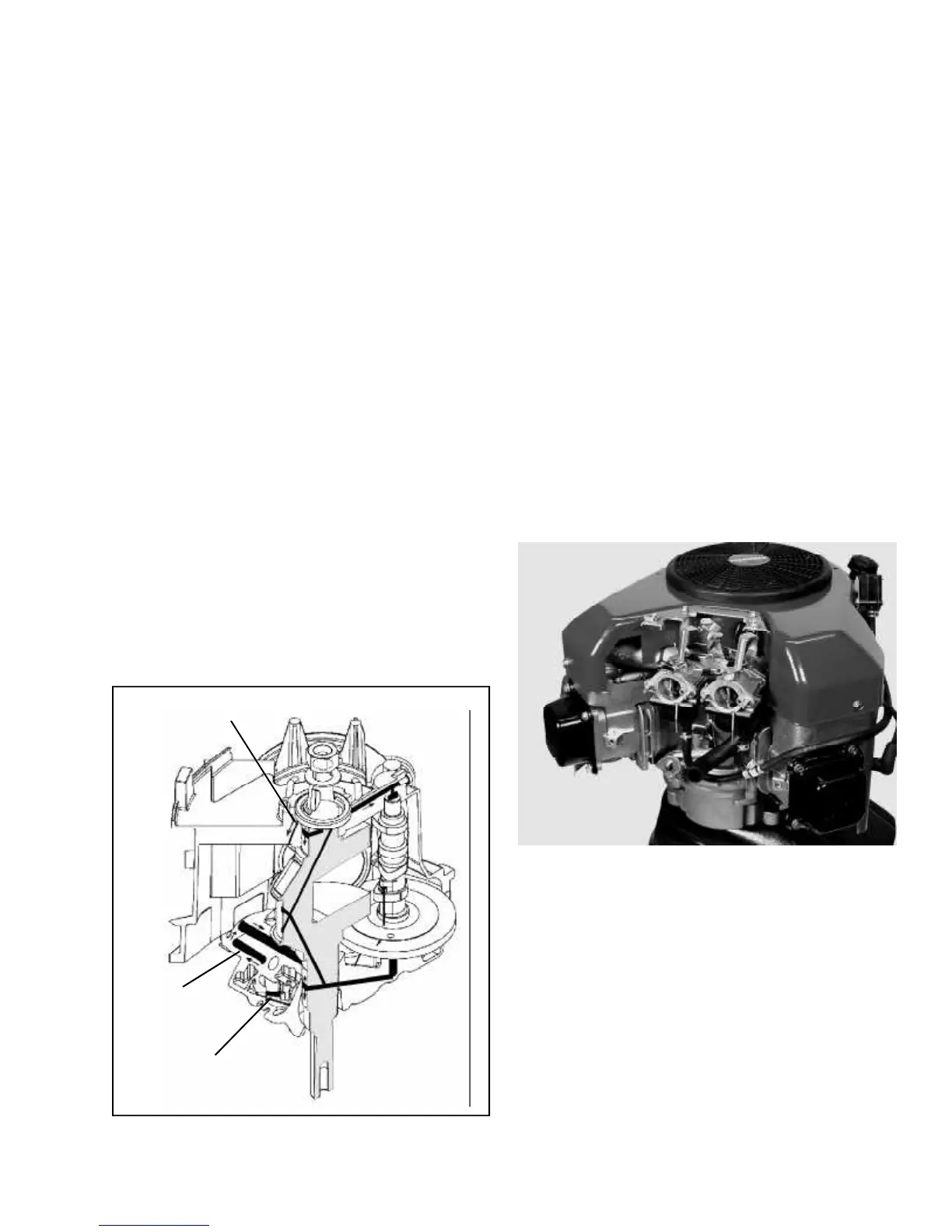

6. Remove the air cleaner assembly. (Cover, Filters,

deflector, control cover and air filter body).

(Illust. 7-2)

7. Remove the flywheel-rotating screen.

8. Remove the blower housing by first removing the

screw holding the dipstick tube and fuel pump to the

blower housing. Remove the remaining three bolts

holding on the blower housing.

9. Unplug the ignition ground wire from the terminal on

top of the ignition modules and remove the ignition

modules.

10. Locate the piston at top dead center (TDC) on the

number one cylinder (lowest cylinder) at the

compression stroke for easier valve train service.

7-2

OIL PICK UP

OIL RETURN

TO OIL FILTER

Loading...

Loading...