5

LET’S GET STARTED

FIGURE 4

STEP 1

Assemble Console Support Bar

IMPORTANT: Do not pull or pinch the Console Wire

during the Console Support Bar installation.

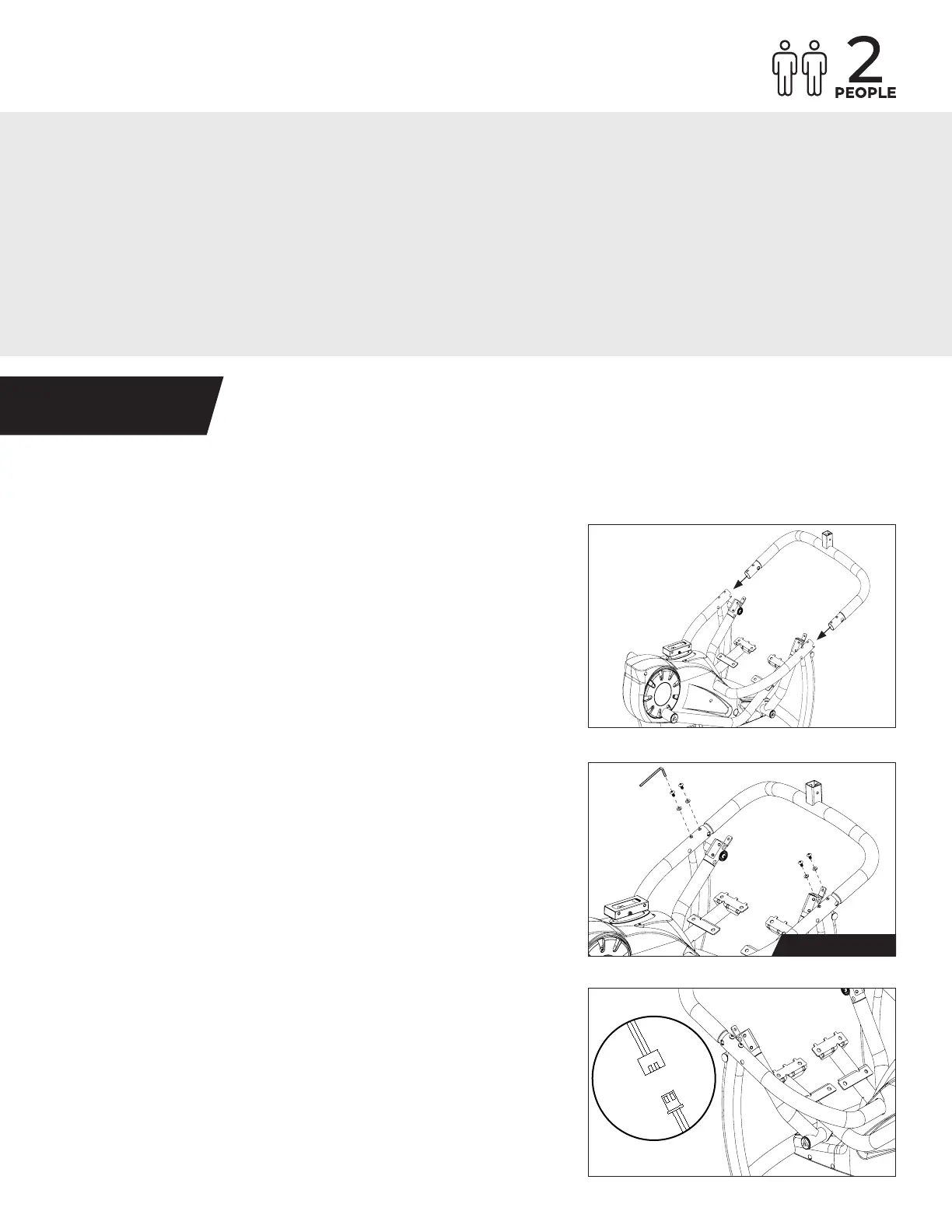

Figure 1: Insert Console Support Bar into the Base.

STEP 1 - INSERT CONSOLE SUPPORT BAR

INTO BASE.

STEP 2 - INSTALL FOUR (4) M8X15 BOLTS

AND WASHERS BY HAND. AFTER THE BOLTS

HAVE ALL BEEN STARTED BY HAND,

PROCEED TO FULLY TIGHTEN ALL FOUR (4)

BOLTS WITH THE 6MM ALLEN.

USE HK2063.

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

AI DRAWINGS

SHEET 2 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: NONE

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

BONNEY LAKE, WA 98391

DRAWING

LT7

Step 1 Hardware

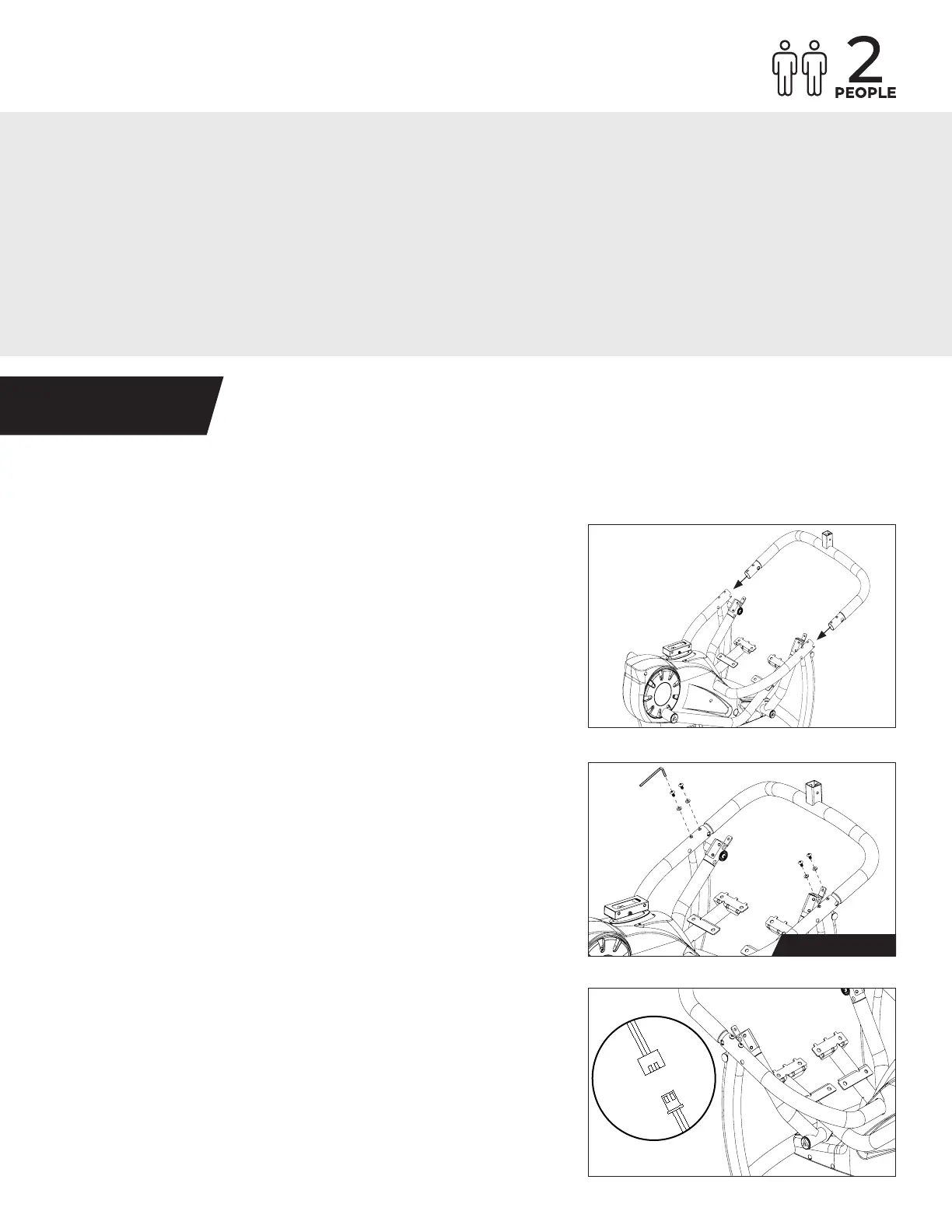

Figure 2: Use the Step 1 Hardware Kit to attach the

Console Support Bar. Insert 4 × Bolts with 4 × Washers

and hand tighten.

Proceed to fully tighten the Bolts with the 6 mm Allen

Wrench.

Figure 3: Carefully connect the Console Wires.

Figure 2

NOTES: The Front, Back, Right and Left of the equipment is labeled on Page 3. Always hand

tighten all bolts or screws in each step before fully tightening with the wrench or screwdriver.

STEP 2 - INSTALL FOUR (4) M8X15 BOLTS

AND WASHERS BY HAND. AFTER THE BOLTS

HAVE ALL BEEN STARTED BY HAND,

PROCEED TO FULLY TIGHTEN ALL FOUR (4)

BOLTS WITH THE 6MM ALLEN.

STEP 2 - INSTALL FOUR (4) M8X15 BOLTS

AND WASHERS BY HAND. AFTER THE BOLTS

HAVE ALL BEEN STARTED BY HAND,

PROCEED TO FULLY TIGHTEN ALL FOUR (4)

BOLTS WITH THE 6MM ALLEN.

STEP 2 - INSTALL FOUR (4) M8X15 BOLTS

AND WASHERS BY HAND. AFTER THE BOLTS

HAVE ALL BEEN STARTED BY HAND,

PROCEED TO FULLY TIGHTEN ALL FOUR (4)

BOLTS WITH THE 6MM ALLEN.

STEP 3 - PLUG CONSOLE WIRE TOGETHER.

MAKE CONNECTION HERE

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

AI DRAWINGS

SHEET 3 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: NONE

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

BONNEY LAKE, WA 98391

DRAWING

LT7

Figure 3

Unpack and Prepare Your Workspace

Follow the instructions on the outside of the box for the easiest unpacking process.

If possible, assemble the equipment at or near the space

in which you intend to use it to avoid moving it later. Ensure you are near a power source.

Unpack all parts and support materials.

Set aside packing materials and clear your work area.

Locate the Hardware Kits inside the box.

They are labeled to correspond with the assembly process.

STEP 1 - INSERT CONSOLE SUPPORT BAR

INTO BASE. BE SURE NOT TO PINCH THE

CONSOLE WIRE ON THE LEFT SIDE WHEN

INSERTING.

REVISIONS

ENGR

DATE

REV

SHT

ZONE

DESCRIPTION

NMS

11/16/2023

A

1

8D

A1: RELEASE FOR TEETER INTERNAL USE ONLY

PARTS LIST

ITEM

QTY

NET DIMENSIONS/DESCRIPTION NOTE

MATERIAL

SHT

REVISION STATUS

SHT

1

REV

A

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

AI DRAWINGS

SHEET 1 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: NONE

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

BONNEY LAKE, WA 98391

DRAWING

LT7

Figure 1

Loading...

Loading...