STEP 4.2 - REMOVE THE WOOD BLOCK

FROM THE REAR OF THE BASE. USE THE 6MM

ALLEN TO REMOVE TWO (2) M10X50 BOLTS

AND WASHERS. THE WOOD BLOCK, TWO

(2) BOLTS, AND TWO (2) WASHERS. THIS

WOOD BLOCK IS FOR SHIPPING PURPOSES.

ALSO REMOVE ONE (1) M10X50 BOLT THAT

IS NEAR THE CENTER LEVELING FOOT. THIS

BOLT IS TO HELP SECURE THE FLYWHEEL IN

SHIPPING.

THE REMOVED HARDWARE AND BLOCK

CAN BE THROWN AWAY AT THE END OF

ASSEMBLY AS THEY WILL NO LONGER BE

USED (BUT WE MIGHT WANT TO HAVE THE

CUSTOMER HOLD ONTO THEM FOR A LITTLE

SO THAT THEY COULD REUSE THEM TO SHIP

THE UNIT BACK IF THEY NEEDED TO).

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

LT7_AI

SHEET 5 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: FULL

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

PUYALLUP, WA 98391

DRAWING

PROJECT NAME HERE

6

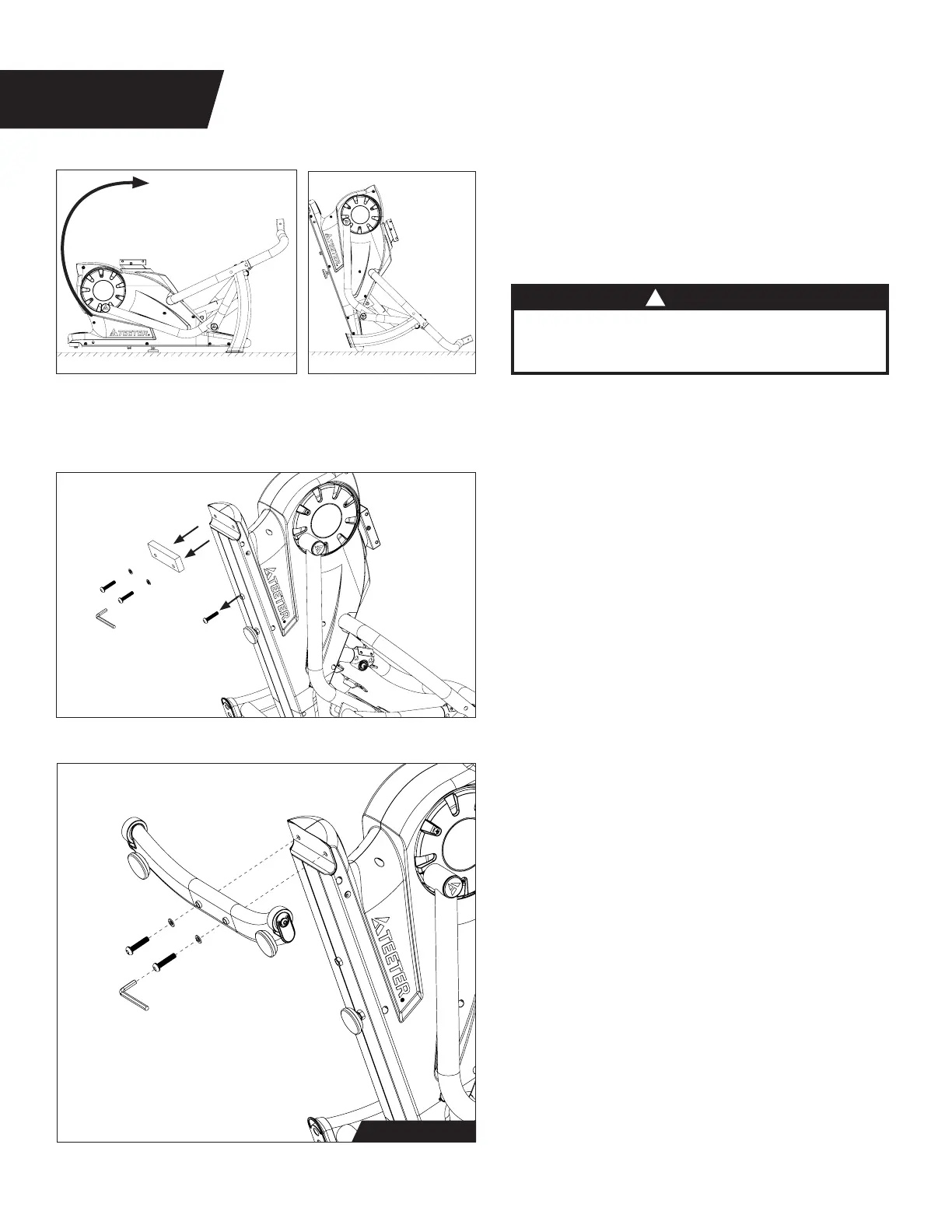

Figures 4-5: Lift the rear Base and tilt the

FreeStep forward so the Console Support

Bar is resting on the ground.

STEP 4.1 - FLIP THE MAHINE FORWARD AND

LET IT REST ON THE CONSOLE SUPPORT BAR.

IT IS RECCOMENDED TO USE SCRAP

CARDBOARD OR A BLANKET ON THE

FLOOR TO PROTECT THE FLOOR AND THE

MACHINE.

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

AI DRAWINGS

SHEET 4 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: NONE

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

BONNEY LAKE, WA 98391

DRAWING

LT7

STEP 4.1 - FLIP THE MAHINE FORWARD AND

LET IT REST ON THE CONSOLE SUPPORT BAR.

IT IS RECCOMENDED TO USE SCRAP

CARDBOARD OR A BLANKET ON THE

FLOOR TO PROTECT THE FLOOR AND THE

MACHINE.

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

AI DRAWINGS

SHEET 4 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: NONE

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

BONNEY LAKE, WA 98391

DRAWING

LT7

CAUTION

!

Use caution to avoid tipping and when

lifting heavy objects.

FIGURE 4

STEP 2

Figure 6: Use the 6 mm Allen Wrench to

remove the 2 × Bolts and 2 × Washers from

the wood block on the Base.

Use the 6 mm Allen Wrench to remove the

1 × Bolt from the Base.

NOTE: Discard wood block and hardware.

They are for shipping purposes only and are

not needed for use of the FreeStep.

Figure 6

Figure 4 Figure 5

Assemble Rear Stabilizer

Figure 7: Use the Step 2 Hardware Kit to

attach the Rear Stabilizer.

Align the Rear Stabilizer with the rear of

the Base and hand tighten 2 × Bolts and 2 ×

Washers.

Proceed to fully tighten each Bolt with the

6 mm Allen Wrench.

Once the Rear Stabilizer is assembled, return

the FreeStep to the upright position by lifting

up on the Console Support Bar until the Rear

Stabilizer is resting on the ground.

STEP 5 - INSTALL THE REAR STABILIZER WITH

THE TWO (2) M10X50 BOLTS AND WASHERS

BY HAND. AFTER THE BOLTS HAVE BEEN

STARTED BY HAND, PROCEED TO FULLY

TIGHTENING ALL TWO (2) BOLTS WITH THE

6MM ALLEN.

USE HK2060.

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

8

A

1234567

D

C

B

C

A

D

B

5 3 16 248 7

AI DRAWINGS

SHEET 6 OF 40

REV

PROJECT:

DRAWN

UNLESS OTHERWISE NOTED

SURFACE ROUGHNESS PER ANSI B46.1

DIMENSIONING PER ASME Y14.5-2009

WELD SYMBOLS PER AWS A2.4

FINISH:

UOS 63RMS ON

MACHINED

SURFACES OR

AS PROCURED

.X

.XX

.XXX

ANGLE

EXPECTATIONS PROPRIETARY

THE INFORMATION CONTAINED HEREIN

IS PROPRIETARY TO EXPECTATIONS AND

SHALL NOT BE REPRODUCED IN WHOLE

OR IN PART OR USED FOR ANY PURPOSE

EXCEPT WHEN SUCH USER POSSESSES

DIRECT WRITTEN AUTHORIZATION

FROM EXPECTATIONS LLC

SCALE: NONE

SIZE:

D

A

TOLERANCES

UNLESS NOTED

=

.1

=

.03

=

.005

=

1

NICK SOLLER

FILLET RADII: .005-.010

CORNER BREAK: .005-.010

ALL DIMENSIONS IN INCHES

EXPECTATIONS LLC

BONNEY LAKE, WA 98391

DRAWING

LT7

Figure 7

Step 2 Hardware

Loading...

Loading...