System Maintenance—

TM

504

TROUBLESHOOTING

AIDS

Introduction

The

following

is provided

to augment

information

contained elsewhere

in this

and other

TM

500 Series family

manuals

when troubleshooting

becomes necessary.

Circuit

Descriptions

Each

manual has

a

section

devoted

to explaining circuit

operating

theory.

Used conjointly with

the

schematics, this

can

be

a

powerful analytic

tool.

Diagrams

Block

diagrams

and detailed circuit

schematics

are

located

on foldout pages in the

service

section

of most of

the

TM 500 Series family manuals.

The

schematic

diagrams

show the component

values and

assigned circuit

reference

numbers

of

each part necessary

to the circuit

design.

Usually

the first

page of the service

section defines

the

circuit

symbols and reference

designators

used in that

particular instrument.

Major circuits

are usually

identifiable

by

a

series of

component numbers.

Important waveforms

and

voltages

may

be

shown

within the

diagrams

or on

adjoining

aprons.

Those portions

of the circuits

located

on

circuit

boards are

enclosed with

a

blue or grey

tint outline.

Cam Switch

Charts

Cam switches shown

on the diagrams are coded on

comprehensive

charts

to

locate

the

cam

number of the

switch contract

in

the

complete switch assembly,

counting

from

the

front,

or

knob end, toward

the rear

of

the switch.

The charts also

indicate with

a

solid

dot

when each contact

is

closed.

Circuit

Board Illustrations

Line illustrations

showing component

locations

keyed

with

a

grid

scheme for each circuit

board

are usually

placed

on the back

of

a

foldout

page

and sequenced

as

close

as

possible

to an associated schematic.

The

GRID

LOG

columns

located near the

Parts

Location Grid keys

each

component

to easy location

on the

board.

Component

and

Wiring

Color Codes

Colored

stripes or dots on

electrical components

signify

electrical values, tolerances, etc.,

according

to

EIA stand-

ards. Components

not color-coded

usually have information

printed on

the

body.

The

wiring

coding

follows the

same

EIA standards

.

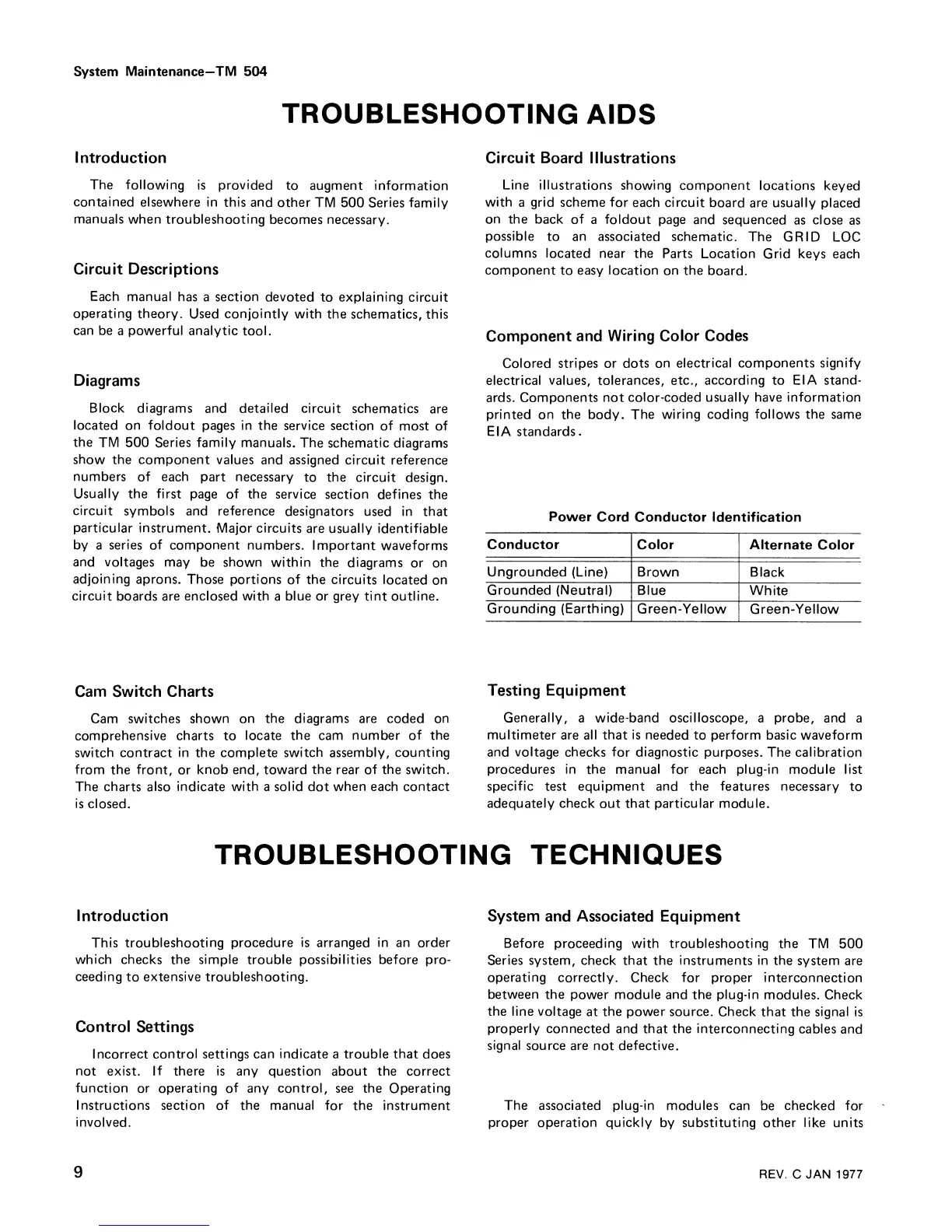

Power

Cord Conductor

Identification

Conductor

Color

Alternate Color

Ungrounded

(Line) Brown

Black

Grounded

(Neutral) Blue

White

Grounding (Earthing)

Green-Yellow

Green-Yellow

Testing Equipment

Generally,

a

wide-band oscilloscope,

a

probe,

and a

multimeter are all that is

needed to perform basic waveform

and voltage checks for diagnostic

purposes. The calibration

procedures in

the

manual for

each plug-in module list

specific

test

equipment

and the features necessary

to

adequately check

out

that particular module.

TROUBLESHOOTING

TECHNIQUES

Introduction

This troubleshooting

procedure

is

arranged

in an

order

which

checks the

simple

trouble possibilities before pro-

ceeding

to

extensive

troubleshooting.

Control Settings

Incorrect control settings can

indicate

a trouble

that

does

not exist. If there is any question

about

the

correct

function

or

operating of any control,

see

the

Operating

Instructions section of the manual

for the instrument

involved.

System

and Associated Equipment

Before

proceeding with troubleshooting

the

TM 500

Series

system, check that the instruments in the

system

are

operating

correctly.

Check for proper interconnection

between the

power module and the plug-in

modules. Check

the line

voltage

at

the power source.

Check that the signal

is

properly

connected

and that

the

interconnecting cables

and

signal

source are

not

defective.

The associated plug-in

modules can

be

checked for

proper operation

quickly

by

substituting other like

units

9

REV.

C

JAN 1977

Loading...

Loading...